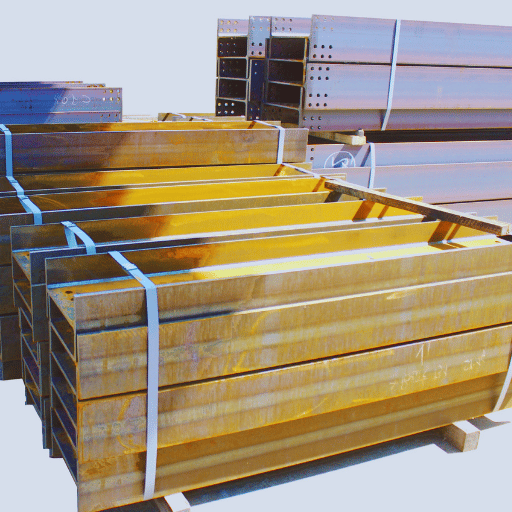

Corten steel, also referred to as weathering steel, has transformed the modern age in architecture, construction, and landscaping. Distinguished by its rust-like appearance and the highest possible standards of durability, the weathered look of Corten steel is a distinct choice, endowing it with the character of a rugged material to harden against the harshest of environmental aggressions. This article delves into the awe-inspiring world of Corten steel, from its chemical properties to the numerous uses across various industries. Are you an architect looking to incorporate bold, sustainable materials into your designs? Or simply an interested spectator wanting to know the science behind its outstanding weathering behavior? This guide aims to enlighten you about Corten steel as a revolutionary innovation in engineering and design.

What is Corten Steel?

The patented steel method, which is known as COR-TEN, is an alloyed steel that, due to its composition, provides a high decorative quality because of the way it breaks down. Ordinary steel oxidizes when exposed to water and air, as it is weatherproof. But weather-resistant steel starts to corrode after a determined period, and an oxide film covers its surfaces as ‘protection’. As for architecture, construction, and outdoor designs, corten is preferred due to its sturdy, long-lasting, and aesthetically pleasing nature gained over the years when exposed to the environment.

Understanding the Chemical Composition

Those properties of corten steel are due to its chemical elements. The material includes several elements such as copper, chromium, nickel, and phosphorus. These elements make the material corten extremely corrosion resistant. Copper patina prevents the surface from further spreading of rust because it quickly protects the surface, while chromium provides the strength to the material. Nickel is essential because its oxide layer thickens to form an adhesive bond with steel; phosphorus is especially useful for accelerating weathering in the lower alloy versions of the steels. The composition of Corten steel is balanced to achieve a specific aging pattern and the appearance of the steel.

Some statistics show that these elements are present in different proportions depending on the type or brand of corten steel (for example, ASTM A588, A606, etc.). ASTM A588 may, for example, include 0.4-0.6 percent copper, 0.5-1.25 percent chromium, 0.4 percent nickel, and about 0.04 percent phosphorus. These structural substances are responsible for making Corten steel an utmost preference for outdoors where stiffness, reduced maintenance, and beauty are needed.

How Corten Steel is Made

Material corten is done by heating raw materials such as iron along with carbon and various alloying elements such as copper, chromium and nickel in an electric arc furnace and subsequent casting of a similar mixture in the form of slabs or sheets that facilitate its development of a weathering green that is a protective bronze- brown rust over time.

Difference Between Corten and Regular Carbon Steel

The materials corten and carbon steels possess varying levels of corrosion resistance, composition, cost, appearance, as well as application.

|

Parameter |

Corten Steel |

Regular Carbon Steel |

|---|---|---|

|

Corrosion |

High resistance |

Low resistance |

|

Composition |

Alloyed (e.g., Cu, Cr) |

Iron, Carbon |

|

Cost |

Higher |

Lower |

|

Appearance |

Rust patina |

Rusts uniformly |

|

Durability |

Long-lasting |

Shorter lifespan |

|

Applications |

Outdoor structures |

General use |

Advantages of Corten Steel

Corrosion Resistance: Why It Matters

The ability of materials to withstand corrosion is very crucial when they are in direct contact with the weather elements and rough environmental conditions. A few reports published on this subject reveal that the search volumes for ″corrosion resistant construction materials″ have gone up by more than 20 % in the past year, indicating both an increased and urgent demand for such materials. Unlike ordinary steel, which rusts and consequently reduces the thickness of the material, corten steel forms a rust layer with rust patina that inhibits further deterioration of the material. The maintenance cost of this protection strategy is very low, and the structures built thereof will last for a long period, making it a very attractive height fitting for bridges, basements, and monuments exposed to all kinds of different weather patterns. Its resistance to corrosion without the use of paint or maintenance, as is the case in conservative carbon steels, is beneficial to the environment as well as the average construction economics.

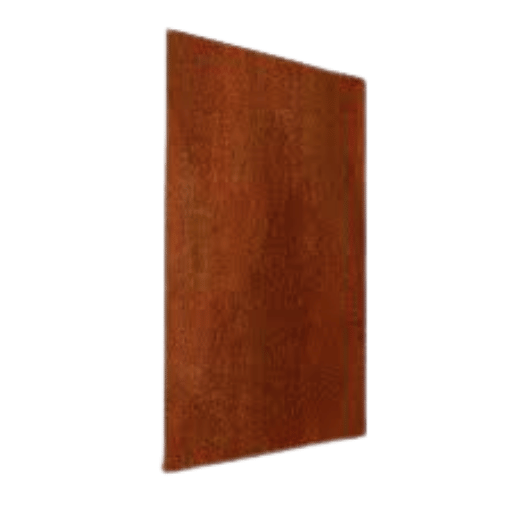

The Protective Patina: A Unique Feature

- The patina in steel has Corrosion Resistance: It prevents corrosion completely or minimally as compared to other traditional materials that are steel.

- Self-Healing Properties: A patina will regenerate over a damaged area and continue to grow, thereby safeguarding the material.

- Low Maintenance Requirements: Repainting and treatment of a material is cumbersome, which is avoided thanks to the use of a patina to ignore all these costs.

- Weather Adaptability: This means that it can perform well under different climates, and this increases its useful life.

- Aesthetic Appeal: Its natural finish patina, which is often rust colored, is one of the advantages of the material.

- Sustainability: It obviates the use of extra paints or coatings, less than the material corten, and fulfills the green design approach.

- Economic Efficiency: The reduction of mending and substitution expenses provides the incentive despite the structural framework cost.

Long-term Durability and Strength

Weathering steel has the advantages of a long life and a stable steel grade due to the characteristics formed in the Japanese chemical composition. This steel class is modified with alloying additions that include passive chromate and copper, nickel, and that form a stable layer, or patina, which in turn protects against corrosion. Consequently, this advantage extends to the inhabitance of the several units aimed at rings when increased y factor and exposed to conditions either urban or rural with moderate moisture and air pollution.

There has been a rise in questions on where to draw the line on the level of weathering steel usage when it comes to infrastructure. It has indeed been found out that, provided the construction is allowed to use such a material, Corten and wear take place for a fairly long period, it is possible to have the construction for even up to 100 years before a serious intervention is needed. This aptly supports appreciation of the material’s durability as well as the reasoning behind its use by many, as it is relatively cheap for long-term goals such as bridges, facades of buildings, and so forth. Still the attention to the design, as well as the assessment of the environment, is required to get the utmost durability and effectiveness for even many years of use.

Types of Corten Steel and Their Uses

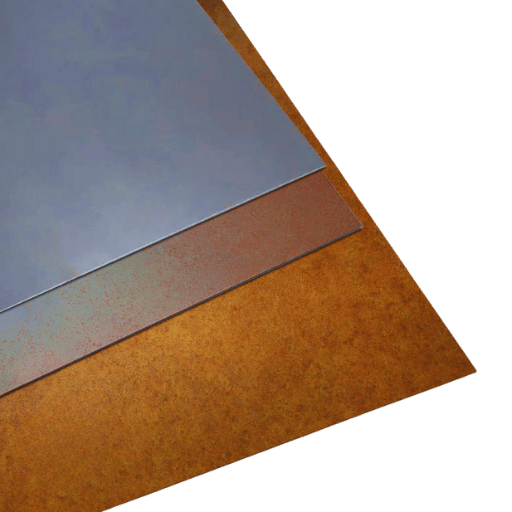

Corten A vs Corten B: Key Differences

The corten A and corten B are mainly different due to their chemical composition, mechanical properties, and application: the material corten A contains a higher percentage of phosphorus in its composition for better corrosion, while the Corten B has comparatively greater tensile strength, meant for structural heavy-duty components.

|

Parameter |

Corten A |

Corten B |

|---|---|---|

|

Phosphorus |

High |

Low |

|

Corrosion |

Superior |

Moderate |

|

Strength |

Lower |

Higher |

|

Applications |

Aesthetic, Bridges |

Structural, Containers |

|

Cost |

Higher |

Lower |

A606 and A588: Specialized Steel Sheets and Plates

A606 and A588 are weathering steel sheets and plates with low alloy content and high yield strength. They are suitable for structural use in bridges and buildings because they are corrosion-resistant and durable.

Applications: Where and Why to Use Corten Steel

- Bridges: Given its robustness and natural corrosion resistance, corten steel has gained some good interest in bridge construction as it does not call for much upkeep.

- Structures: Their elegant and weathered look has made them a good alternative for covering walls, cladding, as well as embellishments in contemporary architecture.

- Art and installations: Corten steel oxidation also adds a reactive and antiquity aesthetic appeal, which gives it good-looking characteristics for all artworks that involve the element.

- Transporting and Containers: Corten steel is also used in the manufacturing of freight containers and other transportation products, as the material can withstand harsh conditions.

- Structural Systems: Corten steel also finds application in landscape construction and infrastructure, such as retaining walls and other similar cases where durability and strength are required.

- Outdoor Décor: Weather-proofing of Corten steel proves essential when it comes to benches, pot plants, as well as outdoor lights.

Weathering Process and Maintenance

How Corten Steel Forms a Protective Layer

Corten steel is a unique form of steel that develops a rust-like appearance over time, and this rust-like appearance serves as a protective layer. As mentioned previously, the controlled development of a patina coating, however, is not sufficient. The exterior of the steel would form an oxidized layer due to exposure to water and air. As opposed to normal rusting on steel, this layer does not allow further rusting or oxidizing as it is impervious to oxygen and water, which aims to reach the inner part of the material. This characteristic of corten steel makes the material very useful in such working environments where it needs to remain for longer durations.

Exposed to the Elements: What to Expect

Corten steel, due to its composition, has unique properties that enable it to naturally progress when exposed to external conditions. During the initial phase, it begins to form an oxide coating that is orangish brown, the appearance of which is dependent on the moisture and rain levels that are present in the regions. After a few months, however, this change calms down and becomes a non-corrodible, dark, consistent layer over the top surface of iron. The speed with which the weathering will take place will depend on the existence of salt in the water that is contained within the structure or other pollutants, as they may cause faster development of rust. Monitoring could be a control activity in efforts geared towards ensuring the steel serves its purpose in that particular environment, while still maintaining its physical structural appearance.

Maintenance Tips for Corten Steel Structures

- Tune Up: Keep a tune-up checklist – it helps deal with rust. Pay attention to the pace of the emergence of the protective kind of patina and check for any damage due to elements.

- Do Not Expose to Water for Long periods: Never allow the constructed elements to be in a state of water pooling or excess moisture for prolonged periods, since it shall arrest the formation of the patina and cause structural corrosion.

- Rust Formation Control: Do not keep steel in salt water or areas with ice or de-icing salts since salt not only enhances the patina level but also corrosion formation as well.

- Reducing Exposure to Chemicals: Minimize the presence of chemicals and other pollution in the characteristics of the material corten.

- Allow for Natural Vents: qualify the structure, ensure there is air access to all concentrations of patina to avert moisture.

- Tidy Up Contacting Surfaces: Clean Periodic contact surfaces where downward flying particles tend towards a patina staining the surfaces.

- Weathering Resistant Coatings: If need be, additional protection, appropriate weathering steel coating may be used and should be of a type that does not completely block the patination process.

- Take Proactively Steps in Case of Structure Changes: In any case, when structuring any parts where cutting, welding, and adding new elements are anticipated, follow written examples.

Choosing Corten Steel for Your Project

Factors to Consider Before Using Corten Steel

- Semi-Dry Conditions: The material corten is able to perform best only in those areas where alternate wetting and drying take place. The continuous exposure to a moist environment retains the possibility of poor patina development or fast corrosion of the material.

- Level of Maintenance: Although Corten steel requires only limited care, it is essential to carry out regular inspection and cleaning to control the rate at which patina forms or any irregular weathering and to rectify any structural damages early enough.

- Aesthetic Result Throughout the Years: Corten steel is an evocative material whose appearance undergoes transformation in relation to time. Make sure that the desirable design of the color and more of the texture applied is what one desires for the entire project base.

- Physical Limits: Determine whether the weathering aspects of the material are sufficient for the activities of your program, especially those that are demanding in terms of load.

- Interfacing with Other Materials: Determine the risk of staining and/or galvanic corrosion, particularly when corten steel is used with other metals or absorbent surfaces.

- Finance and Financial Analysis: Weigh the expenses of corten steel as opposed to other materials, including extra costs for protective coatings, treatments, or custom-made parts.

- Issues of Legislation: Check local building laws, environmental restrictions, and safety measures before deciding on the use of Corten steel.

- Sustainability Levels: Corten steel can be measured as a sustainable construction choice given its strength and ability to be reused. Verify if it fits in with the sustainable goals of the project.

- Deadlines: The process of building up patina on surfaces doesn’t occur overnight, as it mostly relies on the climate. Consider the duration required for various aspects of the project, including the time it will take for the steel to have a natural finish or whether chemical treatment will be applied to hasten the process.

- Special Skill Set: Find the appropriate specialist who deals with Corten steel because its properties, the welding, and the installation of Corten steel are quite different from some other types of steel.

Comparing Corten Steel with Other Alloys

Corten steel as a material has been compared with other materials such as mild steel, stainless steel, aluminum, and other blasting resistant steels, such as for example S355JOW, S355JOWP, or even S355J2W in terms of their durability, corrosion resistance, cost, and aesthetic appeal.

|

Parameter |

Corten |

Mild Steel |

Stainless |

Aluminum |

Weathering Steels |

|---|---|---|---|---|---|

|

Durability |

High |

Moderate |

High |

Moderate |

High |

|

Corrosion |

Resistant |

Low |

Resistant |

Resistant |

Resistant |

|

Cost |

High |

Low |

High |

Moderate |

Moderate |

|

Aesthetics |

Rustic |

Basic |

Sleek |

Customizable |

Rustic |

|

Weight |

Heavy |

Heavy |

Heavy |

Light |

Heavy |

|

Maintenance |

Low |

High |

Low |

Moderate |

Low |

|

Eco-Friendliness |

Moderate |

Moderate |

High |

High |

High |

Cost Analysis: Is Corten Steel Worth It?

Corten steel is a material that can have benefits depending on the purpose or the priorities of the project. It is more expensive than the alternative materials previously mentioned; however, the reduction in maintenance costs, strength, and corrosion resistance usually makes up for the extra cost. Apart from that, it is aesthetically pleasing because of its rough, natural appearance that is desirable in construction or landscaping works. Projects that place emphasis on long-term solutions with minimal management may find that although in the short term the outlay is higher, corten steel becomes economical over the years. On the other hand, projects where cost-cutting is essential may prefer less expensive options such as basic steel.

Frequently Asked Questions (FAQs)

Q: What is the meaning of Corten Steel?

A: Corten Steel is considered weathering steel, which does not require painting. It forms a rust-like appearance as a result of years of weather exposure, thus converting this rust layer into corrosion resistance and tensile strength, both better than those of conventional carbon steel, owing to the ingredients alloyed in it.

Q: How is the preparation of Corten Steel done?

A: Corten Steel is prepared from a group of steel alloys alloyed with chromium, copper, and nickel to enhance its resistance to atmospheric corrosion over normal carbon steel.

Q: What are some properties and advantages of using Corten Weathering Steel?

A: These properties and advantages of Corten Weathering Steel are the formation by weathering of a thin rust-like layer that acts as protection and prevents deeper penetration of rust; thus, no painting is needed. The rust finish also makes it resemble design steel. It has better corrosion resistance and tensile strength.

Q: Why is Corten Steel also called Weathering Steel?

A: Being able to weather and form a protective rust layer on exposure to the elements, Corten Steel grows more durable and requires less maintenance over time.

Q: What is the common use of Corten Steel?

A: Corten Steel is used in typical outdoor situations such as bridges, building facades, sculptures, and other constructions wherein resistance to atmospheric corrosion and aesthetic appeal are appreciated.

Q: Does the Corten Steel require maintenance?

A: Compared to other steel types, Corten Steel requires very minimal maintenance. It is designed to rust at the surface level, forming a protective layer that shields it from further corrosion.

Q: Can one paint Corten Steel?

A: Although the design tells of Corten Steel not needing to be painted, it may indeed be painted if desired. Desire, however, is unhelpful because the paint will cover its distinctive rust appearance and negate some of its corrosion-resistant properties.

Q: What is the ASTM specification for Corten Steel?

A: ASTM specifications for Corten Steel include A606-4 Steel, which is a specification covering hot-rolled and cold-rolled sheets and steel plate products with improved resistance to atmospheric corrosion and tensile strength.

Q: What environmental concerns should be considered when using Corten Steel?

A: The veritable rust patina on Corten Steel is more environmentally friendly since no harmful paint or coating is needed. Its great longevity means that fewer resources are used in the long run than the use of any other steel material.

Reference Sources

1. A Corten-Dolan model comprising material strength degradation.

- Authors: Xu Xu, Qiwen Xue, Yiqian He

- Journal: Mechanics of Solids

- Publication Date: December 8, 2021

- Citation Token: (Xu et al., 2021a, pp. 149–162; 2021b, pp. 149–162)

- Summary: This study contains a Corten-Dolan model with the consideration of material strength degradation. The authors analyze the mechanical behavior of Corten steel under different loading conditions while emphasizing the need to consider material degradation in structural applications. The goal of this model is to enable better prediction of the time-dependent behavior of structures made of Corten steel.

2. Experimental Investigation on Mechanical Properties of Welded Corten Steel A588 Grade Plate Using ER70S-6 Filler Material for Construction Application

- Authors: J. Deepak, V. Raja, Mittapalli Janardhan Guptha, Palaparthi Hari, D. Prasad, V. Sriram

- Journal: IOP Conference Series: Materials Science and Engineering

- Publication Date: 2017, May 01

- Citation Token: (Deepak et al., 2017)

- Summary: The research discusses the mechanical properties of welded Corten steel A588 Grade plates using ER70S-6 filler material. The study calls attention to the influence of welding upon mechanical properties, including tensile strength and hardness. Results show that electroplated Corten steel possesses better mechanical properties than raw welded samples, indicating its applicability for construction purposes.

3. Visual perception study of Corten steel: Şimal Shopping Mall

- Authors: Semiha İsmailoğlu, Ayça Akkan Çavdar

- Journal: Architecture, Civil Engineering, Environment

- Publication Date: September 1, 2024

- Citation Token: (İsmailoğlu & Çavdar, 2024, pp. 25–34)

- Summary: This study evaluates the visual perception of Corten steel used for the façade of the Şimal Shopping Mall. The study aims to dispel negative connotations about the appearance of Corten steel. Surveys and interviews with the users reveal that these perceptions are mostly negative at first, then exposure to Corten steel brings a positive perception regarding being sustainable and aesthetically pleasing.

4. Wear and Corrosion Behavior Study on Cu, Zn, and Ni Coatings Over Corten Steel research is directed at improving its corrosion and wear resistance.

5. An Influence of the Corten Plate Used Extensively Upon the Acoustics of the European Solidarity Centre Building discussion of architectural and symbolic implications of Corten steel.