ASTM A105 carbon steel finds extensive use in manufacturing and engineering, prominent for its outstanding mechanical properties and cost parameters. This blog post aims to provide a complete and thorough overview of ASTM A105 carbon steel concerning its composition, properties, and typical uses. Whether procurement professionals, engineers, or just curious about industrial materials, this guide will impart the key insights to appreciate why this steel grade is constantly used in crucial components like flanges, fittings, and valves. We will analyze everything about ASTM A105 carbon steel, including its strength, durability, the industries in which it is used, and how it is affected by modern-day manufacturing.

What are the Mechanical Properties of A105 Steel?

The ASTM A105 carbon steel is high in quality with mechanical properties; hence, it is suitable for pressure systems and industrial components. ASTM A105 steel has tensile strength ranging from 70,000 to 95,000 psi, yielding 36,000 psi as its minimum strength. It possesses good ductility and impact strength, resulting in satisfactory performance of ASTM A105 steel under varying temperature and pressure conditions. Besides, ASTM A105 steel also offers excellent machinability and weldability, making it the go-to option for fabrication without compromising strength. Owing to all these properties in the A105 steel grade, it is widely selected for making flanges, valves, and other highly critical purposes.

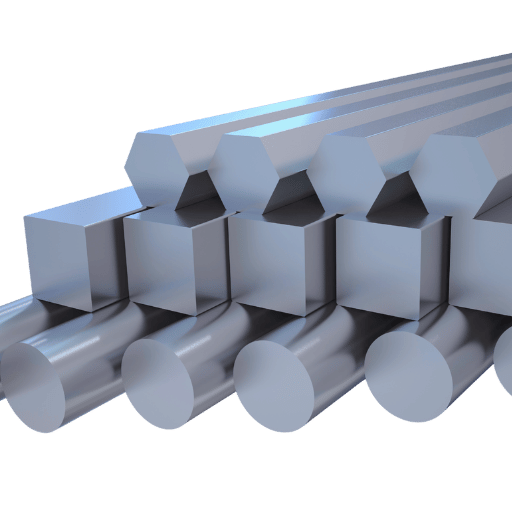

Understanding the specification for A105 Carbon Steel

Carbon steel A105 is the ASTM specification for forged carbon steel piping components such as flanges, fittings, and valves. Its use is primarily in pressure systems under ambient temperatures and the like. Variations in composition that restrict carbon, manganese, phosphorus, sulfur, and silicon are outlined within the specification to guarantee material consistency and performance. A105 carbon steel has some mechanical properties to complement these, such as tensile strength, yield strength, and elongation, to guarantee its use in critical applications. These properties ensure stability, reliability, and durability in demanding environments.

How ASTM A105 Forgings Behave Under Pressure Systems

ASTM A105 forging is superior in pressure systems performance by strength, ductility, and resistance to deformation. These forgings possess uniform material composition and thereby present uniform performance under varying pressure and temperature conditions. A105 forging mechanical properties bear tensile and yield strength to resist internal pressures and failure. Their resisting corrosion and mechanical wear properties make them reliable in prolonged operation and pressure-containing applications, thus making the forgings appropriate for critical systems.

Exploring Heat Treatment Processes for A105

Heat treatment processes for A105 forgings are carried out to improve mechanical properties, thereby ensuring optimal performance in severe applications. The primary heat treatments are normalization and tempering. In normalization, the material is heated above the upper critical temperature and then cooled in air to refine the grain structure, thereby obtaining strength and toughness. After this treatment, the metal will be reheated at a lower temperature and cooled slowly, reducing hardness and increasing ductility and resistance to stresses during tempering. These processes work toward developing the particular strength, ductility, and wear resistance of A105 forgings to carry out very critical pressure-containing applications.

Why is Chemical Composition Important for A105 Carbon Steel?

Key Elements in ASTM A105 Steel

The chemical makeup of ASTM A105 steel is very crucial as it ensures that the target mechanical properties and performance conditions are met in heavy-duty operations. Important elements include:

- Carbon (C): Imparts strength and hardness, with a reasonable amount of ductility. The carbon content is limited to 0.35% to maintain this balance.

- Manganese (Mn): This makes it tough and abrasion-resistant, with limits between 0.60% and 1.05%.

- Phosphorus (P) and Sulfur (S): Controlled to minimal levels, usually 0.035% maximum, to reduce brittleness and promote overall material integrity.

- Silicon (Si): Increases hardness and strength and is usually present in amounts ranging from 0.10% to 0.35%.

This carefully balanced composition of the elements ensures that A105 steel provides all the necessary strength, toughness, and other application performances at high pressure and temperatures.

How Chemical Composition Affects the Performance of Piping Components

The chemical composition of piping components affects their mechanical properties and corrosion resistance, rendering them more suitable for one application over another, as specified in the specification. Major elements like carbon govern the strength and hardness of the material, whereas manganese governs ductility and wear resistance. The control of trace elements like phosphorus and sulfur lessens brittleness and enhances strength and integrity under stress. On the other hand, with chromium or molybdenum present, corrosion and temperature resistance are highly favored. In other words, a balanced composition between such elements should be achieved to ensure adequate performance under demanding conditions like high-pressure and high-temperature environments.

The Role of Manganese in A105 Steel

Manganese, an alloying element, is essential in A105 steel, primarily as a deoxidizer and contributor to the mechanical properties. It induces strengthening, hardenability, and wear resistance so that it can be used in heavy-stress and high-pressure industrial environments. Usually, the manganese content in A105 steel is between 0.6% and 1.05%, and the levels are controlled to balance ductility and tensile strength.

Another vital function of manganese is counteracting the undesirable effects of sulfur, which usually occurs as an impurity. Manganese reacts with sulfur to form manganese sulfides instead of iron sulfides, thereby minimizing hot-shortness. This condition impedes steel’s workability at high temperatures. Manganese also assists heat treatment, assuring the steel’s good performance throughout thermal and mechanical stresses. Manganese is an indispensable element for forging high-grade A105 steel in critical applications.

How is A105 Steel Forged for Piping Applications?

Steps in the forging Process for Carbon Steel

- Heating the Raw Material: The carbon steel is placed in a furnace to be heated to a uniform temperature, while the usual temperature range is between 2,200°F (1,200°C). This condition makes the steel malleable for forging.

- Forming the Shape: When the steel is hot, it is put into dies or placed under a press to take its shape. Controlled force is used at this stage to provide precision in dimension and structure.

- Quenching: It is the rapid cooling of steel in either water or oil after forming. Although this need not be done, it helps to get the hardness and strength of the material by changing the microstructure.

- Tempering: Tempering reduces brittleness and increases toughness by reheating the forged steel to a lower temperature, followed by slow cooling. This provides an acceptable balance between strength and ductility.

- Finishing and Inspection: Forged parts go through machining processes to their required specifications. Every piece undergoes inspection for quality, dimensions, and defect checks before acceptance for piping applications.

Advantages of Using carbon steel forgings for piping

- High Strength and Durability: All carbon steel forgings possess mechanical strength and durability, making them suitable for applications in a piping system that requires high pressure.

- Cost-Effectiveness: Carbon steels are cheaper than other types of materials, and while providing striking performance, they can be a cost-effective solution for any industrial application.

- Versatility in Applications: Carbon steel forgings are customized to various specifications, so multiple applications will be attempted in the oil and gas, power generation, and chemical processing industries.

- Resistance to Wear and Tear: Carbon steels resist wear excellently because of their strong physical properties, making them suitable for long-term application in harsh settings.

- Ease of Maintenance and Repair: Carbon steel forgings are easy to maintain and repair, resulting in lower downtime and ultimately ensuring the piping systems remain efficient in the long term.

Common Uses of Forged Fittings in Industry

- Oil and Gas Industry: They are essential for high-pressure pipelines, processing plants, and refineries because of their strength and resistance to harsh environments.

- Chemical Industry: They are used in any system with high corrosion resistance and temperatures.

- Power Generation: The plant considers steam, gas, and nuclear power plants, especially their systems that operate at high pressure and temperature, of the utmost importance.

- Construction: Also used in plumbing, heating, and ventilation setups and structural frames for reliability and longevity.

- Marine Applications: These are used in shipbuilding and for offshore platforms, as they can withstand extreme conditions and resist wear.

What Heat Treatment Methods are Applied to A105 Steel?

Importance of Normalizing and Tempering

Normalizing and tempering are heat treatments for A105 steel used to enhance its mechanical properties and to ensure it works satisfactorily in arduous ventures. Normalizing in short refines the grain structure, boosting strength, toughness, and an adequate level of uniformity. Tempering releases the residual stresses retained in the material during normalizing, followed by adjusting the hardness to attain the desired balance of ductility and strength. These processes, combined, make A105 steel fit for holding pressure, working for durability, and serving as a reliable material for industrial and structural works.

How to Anneal A105 Steel for Durability

Annealing of A105 steel is a heat treatment generally applied to increase ductility, reduce internal stress, and obtain better machining properties for more demanding applications. This involves slow heating in the temperature range from 1550°F (843°C) to 1650°F (899°C), depending on the desired property and the thickness of the material. After reaching the temperature, the steel is soaked for a period sufficient to allow uniform heat penetration. This action is necessary for carbon steel forged components.

After soaking, the steel is cooled at a controlled rate; often it is cooled inside the furnace or in other media that prevent hardening. Controlled cooling may minimize distortion and residual stresses and give a fine-grained structure suitable for durability and performance.

The microstructure of annealed A105 steel comprises an equal quantity of ferrite and pearlite. This distribution yields the mechanical property of higher elongation and lower hardness. The steel possesses mechanical qualities that are sought after when machining or welding is done on the product or when the product undergoes dynamic loading. Adherence to the proper annealing methodology ensures that the material complies with ASTM specification requirements and meets structural and industrial use performance criteria.

Impact of Quench Processes on A105 Steel Strength

Quenching mostly determines the strength and hardness of A105 steel. By quenching, a newly heated material is cooled rapidly, and thereby, its microstructure is altered to increase hardness and tensile strength while reducing ductility. For specific applications, the material must be high-strength and wear-resistant. Poor water quenching might cause residual stresses or distortion resulting from the object’s functioning under consideration. Industry standards must be strictly followed to control the quench rate and cooling medium.

Where are A105 Carbon Steel Flanges & Fittings Used?

Applications in Pressure Vessel Systems

A105 carbon steel flange and fitting find extensive application in pressure vessel systems due to their strength, durability, and ability to withstand high pressure and temperature. These components are found, among others, in the oil and gas, chemical processing, and power generation industries, where they connect pipes, valves, and equipment firmly. Compatibility with high-pressure and high-temperature systems makes this passive component reliable for critical applications.

Significance in Higher-Temperature Service Settings

Components destined for higher-temperature service must be engineered to ensure system reliability and safety. Materials so employed must have excellent thermal stability, resist oxidation, and retain their mechanical properties under long hours of heat exposure. This ensures uniform performance and limits the chances of failure under extreme conditions, such as those found in power plants and chemical reactors.

Selecting the Right Valve for Your Pressure System

Selecting the appropriate pressure system valve considers key factors such as system pressure, temperature, fluid handling, and specification of forged materials. Firstly, identify the operational ranges of pressure and temperature, as this directly relates to the material and design requirements of the valve. Considering the mechanical properties of the material for the valve and its compatibility with the fluid being handled by the system will create resistance against corrosion and leakage. Their valve control capacity could then be evaluated to allow for regulating, isolating, or diverting flow within the scope of application of the specification. Finally, the valve should be sized correctly so that its specifications match the flow rate in the system, which will help optimize performance and safety.

Frequently Asked Questions (FAQs)

Q: What is ASTM A105 carbon steel?

A: ASTM A105 is a specification covering forged carbon steel piping components. Carbon steel forged components are generally used for making flanges, fittings, and valves, which find application in pressure systems at ambient and higher temperatures.

Q: How is ASTM A105 carbon steel used in weld applications?

A: With its chemical composition and mechanical properties, ASTM A105 carbon steel is suitable for weld applications. It is used in piping systems, especially where weld strength and integrity are paramount.

Q: What are the ASTM A105 pipe fittings used for?

A: ASTM A105 pipe fittings are used for standard pressure systems and as steel forgings for piping applications. They are also used for seamless component joining in the oil and gas, petrochemical, and power generation industries.

Q: How does the ASTM A105 vary from the alloy steel?

A: ASTM A105 is the more commonly used designation for carbon steel material, especially for pressure systems in ambient and higher-temperature service. This contrasts with alloy steel, with other alloying additions promoting specific properties.

Q: What consideration is there regarding the hardness of ASTM A105?

A: The hardness of ASTM A105 is a very critical consideration, especially for service in pressure systems, which is stipulated in the specification for forged materials. The hardness of the material must satisfy specific hardness requirements so that the material can withstand the operating pressures and temperatures.

Q: What is the importance of ASME Standards about ASTM A105?

A: ASME Standards often refer to ASTM specifications, which, in the case of ASTM A105, ensure the consistent quality and performance of certain key elements, such as forged carbon steel piping components and pipe fittings used in pressure systems.

Q: Is ASTM A105 meant for higher-temperature service?

A: ASTM A105 is meant for ambient and higher-temperature service in pressure systems, making it a versatile choice in many industrial applications.

Q: What does “followed by quenching and tempering” mean?

A: This term means a heat treatment process applied to the ASTM A105 carbon steel to improve its mechanical properties. This enhances its durability and toughness for more demanding applications.

Q: Why is ASTM A105 the most commonly accepted material grade for piping components such as flanges?

A: ASTM A105 is the preferred material grade for flanges because of its excellent mechanical properties, weldability, and applicability for service in pressure systems at various temperatures.

Reference Sources

1. An Experimental and Numerical Study of Friction Coefficient for Steel A105 under Different Lubricants at High Temperature: This study is relevant for understanding ambient- and higher-temperature service performance.

- Authors: P. Kahhal et al.

- Published In: Tribology Transactions

- Publication Date: August 10, 2021

- Citation Token: (Kahhal et al., 2021, pp. 25–31)

- Summary:

- This research focused on determining the shear friction coefficient of A105 steel at high temperatures (1050°C) with different lubricants, including graphite, mica, and glass powder.

- The study revealed a coefficient of friction of 0.62 for dry samples and considerably lower values for lubricated samples, thus confirming that the lubricants effectively reduce friction.

- Methodology:

- Compression ring tests, along with finite element analysis of deformation in the inner diameter of the specimen, were carried out, enabling a comprehensive evaluation of friction coefficients.

2. ASTM A105 equivalent Indian Standard – This specification is for unwelded wrought carbon steel pipe fittings and is therefore essential to an engineering project.

3. Carbon steel