Regarding the usage of steel and metallic tubes, accuracy and cost-effectiveness cannot be overemphasized. For example, the correct equipment will go a long way in the case of a contractor, a plumber, or even in simple cases where one takes up some simple basic construction, such as fixing the sink. For various reasons, including but not limited to achieving a precise cut in the shortest possible time and minimizing the wastage of unnecessary materials, metal or steel pipe cutters are essential tools. The article below discusses the critical components, benefits, and uses of steel pipe cutters so you can find the right one to use. Should you be keen to improve your ability to work and produce better results, the following guide will offer you relevant information and ideas to help you make better choices.

Understanding Steel Pipe Cutters

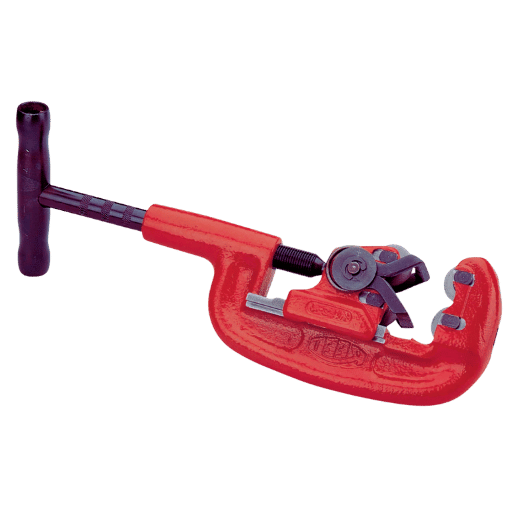

Specialized instruments known as steel pipe cutters are used to precisely and efficiently sever steel pipe sections. They are usually made of a sharp cutting wheel or blade, with an element for applying steady pressure to perfect the accuracy of the cut and avoid any damage. The effectiveness and efficiency of these powerful tools make them perfect for construction, plumbing, and manufacturing, to name a few practices. These strong and durable steel pipe cutters are designed in several types depending on the size of the pipes to be cut and the purpose of use. It is therefore necessary to set the diameter of the pipe, begin its treatment, and cut it with the appropriate cutter till the intended end is achieved. This will be more the case if it is a PVC pipe or copper tubbing.

What is a Steel Pipe Cutter?

High-strength tools such as steel pipe cutters are designed to cut steel pipes accurately and precisely. They do this by exerting compressive force along the circumference of the pipe and, therefore, cutting the pipe in an organized manner without applying bending forces. This is beneficial in various occupations, such as plumbing or manufacturing industries, where the pipes should be joined or used in a system precisely and correctly.

Types of Steel Pipe Cutters

|

Type |

Usage |

Material |

Pros |

Cons |

|---|---|---|---|---|

|

Manual |

Basic cutting |

Steel |

Portable |

Slow |

|

Hacksaw |

Versatile |

Various |

Affordable |

Labor-intensive |

|

Band Saw |

Precision |

Steel |

Clean cuts |

Bulky |

|

Reciprocating Saw |

Tight spaces |

Various |

Versatile |

Noisy |

|

Plasma |

Fast cutting |

Thick steel |

Precise |

Expensive |

|

Ratchet |

Confined areas |

Various |

Adjustable |

Limited size |

|

Spring-loaded |

Adjustable |

Various |

Precise |

Requires skill |

|

Cold Cut Saw |

Heavy-duty |

Steel |

Efficient |

Stationary |

How Steel Pipe Cutters Work

Steel pipe cutters score the pipe with a sharp rotating blade until the pipe is finally cut through. Inside the pipe cutter, the pipe is first secured with the help of an adjustable mouthpiece that facilitates the process of cutting the pipe with great accuracy. When the pipe is in place, the rotating blade or wheel is turned around with even force to cut through its surface into its thickness, which is significant in an inside pipe cutter.

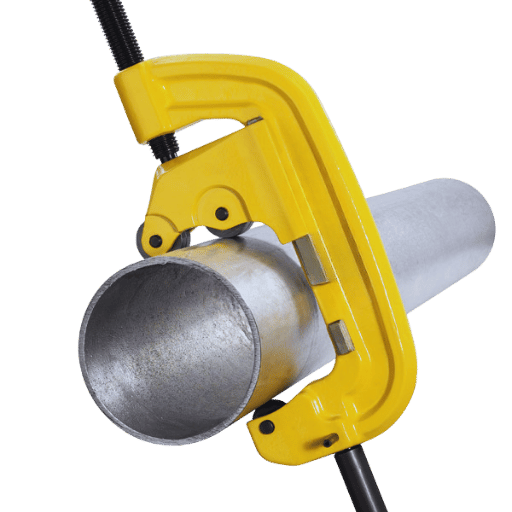

New-generation pipe cutter designs have incorporated elements such as easy-to-grip handles to improve ease of use, the ability to adjust the depth of cut, and durable construction shaped by the material being used. Specialized tools like rotary pipe cutters are ubiquitous in instances where clean cuts without burrs are needed, especially in several plumbing works, HVAC installation, and even piping in industrial processes.

The thickness, the available space in the setting, and the accuracy needed often dictate the type of steel pipe cutter to use. Manual cutters, for example, are very effective in tight spaces because they are small in size, while powered ones, such as plasma cutters and cold cut saws, have proven the best when cutting large and heavy-duty materials. Applying steel pipe cutters guarantees efficiency, safety, and accuracy in many contexts.

Selecting the Right Pipe Cutter

Factors to Consider When Choosing a Pipe Cutter

- Pipe Material: Various pipe cutters are specific to the material of the pipe, e.g., cutters for steel, copper, plastic, and pvc pipes are available. Hence, this will ensure the cut’s cleanliness and avoid unnecessary damage to the tool. Choosing the right cutting tool for a pipe made of a specific material is compulsory.

- Pipe Diameter: The cutter that will be used must fit the diameter of the pipe being tied. The cutting devices are sometimes universal, whereas some are only available for specific pipe dimensions.

- Cutting Environment: Consider the environment where the project will be done, such as bringing in some equipment for cutting purposes in limited spaces, whether a power supply should be available for some equipment, and whether it requires portable or stationary cutting equipment.

- Precision Requirements: Smooth cuts are also preferred in cases where cutting must be exact. Proper cutters, such as powered or rotary cutters, as well as heavy-duty cutters, are required.

- Frequency of Use: If the cutting task is occasional, then simple steel pipe cutters would be enough. However, if the work is regular or continuous, power-operated cutters would be the best savers in terms of cost and time for robustness and power.

Capacity and Size of the Cutter

When choosing a pipe cutter, it is essential to consider the capacity and size since they determine its suitability for various applications, including cutting copper tubes. Pipe cutters are constructed to fit specific diameter pipes, and knowing such construction limits ensures maximum efficiency. For instance, hand cutters are usually designed for smaller pipes, as they fit most 2-inch diameter pipes and can be used for basic home plumbing or light-duty cutting work. In contrast, steel pipe cutters are designed to cater to a much larger pipe, with some of them able to cut to a diameter of more than 12 inches, which is required in infrastructure or oil and gas industry areas.

It could further be said that the material to be cut also determines the size of the cutter. For instance, cutters with specific sizes and functions, such as cutting PVC or plastic tubes, which are much softer than metals, may require less time and effort when working on the materials above. However, hard metals such as steel or cast iron require large-sized, heavy cutting tools that can produce a lot of force when cutting them. These days, pipe cutters with designs can create more than one pipe diameter using the same tool to enhance user capability and savings. Knowing the cutter’s dimensions and capacity enables full utilization of such a tool in long and hard jobs without causing unnecessary wear.

Effective Use of Steel Pipe Cutters

Techniques for Cutting Steel Pipe

- Mark the Cutting Line Accurately: Extend a tape measure along the length of the steel pipe until the desired cut point is reached. With a continuous marker stroke, trace the line so it bisects the circumference; the visible mark will guide the blade and help avert drift.

- Secure the Pipe Firmly: Position the pipe snugly in a heavy-duty vice or purpose-built pipe clamp, tightening the jaws until noticeable flex disappears. A stable hold prevents the workpiece from rocking or shifting during the operation, protecting both the conduit and the operator.

- Select the Appropriate Blade or Cutter: Choose a rotary pipe cutter or a bi-metal saw blade specified for high-carbon steel; inspect the teeth for nicks and examine the weld line for signs of fatigue. An undamaged edge bites evenly into the material and spares the user from repeated passes.

- Apply Consistent Cutting Pressure: Crank the threaded screw of a handheld cutter in small increments, letting the wheel carve a groove rather than forcing the handle. Steady, measured grip permits the steel to yield gradually, maintaining the circular profile for later fittings.

- Finish the Cut Edges: Deburring a fresh edge with a dedicated hand tool or a fine-file fling rounds any sharp lip the blade leaves. Removing these whiskers protects personnel and ensures that seals and couplings seat without obstruction.

Safety Tips for Using Pipe Cutting Tools

- Wear Protective Gear: Safety goggles and gloves must be worn to prevent bits of metal from hurting your eyes and sharp edges from cutting your hands during the cutting operation.

- Inspect the Tool Before Use: The cutter for steel pipe cutters has to be checked to see if there is damage, especially dull blades or any part that might have been loosened, for safe and efficient cutting.

- Secure the Pipe Firmly: The pipe to be cut should be held firmly inside the vise using any clamp or pipe to prevent movement that may cause accidents.

- Cut in a Clear Workspace: Avoid clutter and any other objects that may cause you to trip or fall while using the tool.

- Follow Manufacturer Guidelines: To prevent pre-code use and pre-ignition risks, all tool use procedures should be followed according to the guidelines provided by the tool manufacturer.

Common Mistakes to Avoid

- Using Dull Cutting Tools: When working with objects that require a cut, a dull cutting tool can cause numerous cut surfaces, among other things, because of increased pressure with reduced control.

- Ignoring Safety Gear: Cuts and burns are potential injuries that may arise from not wearing appropriate personal protective equipment, such as gloves or goggles.

- Incorrect Tool Selection: When an improper tool is selected for use on a particular material or workpiece, it can affect not only the effectiveness of the work but also its safety, as the workpiece may be damaged or even harmed.

- Rushing the Process: The risks of cutting at high speeds or using steel pipe cutters too hard are mistakes such as cutting at an angle or slipping the tool from the hand, which may cause injury or damage.

- Neglecting Regular Tool Maintenance: Tools not cared for—including sharp blades, clearing built-up materials, and inspecting for damage—can not provide optimal use and will contribute to dangerous conditions.

Maintenance Practices for Steel Pipe Cutters

Cleaning and Caring for Your Cutter

Maintaining steel pipe cutters in good working order is an important aspect that will make them last longer and work better. Always clean the cutter right after use to avoid the accumulation of any debris, dirt, and residual material. Wipe off the blade and its mechanism with a soft cloth or a small synthetic brush while removing dirt particles. When the remaining residue is considered stubborn, a light and safe solvent may be applied to the metal surface, and wipes must follow to avoid corrosion, especially with heavy-duty tools.

Check the sharpness or deterioration of the blade regularly because it is the part involved in cutting. A well-maintained cutting edge has no problems in cutting materials, but if it is blunt, it causes undue pressure on the tool. The solution to a dull cutting edge of a blade is stated in the instructions given by the manufacturer, which include ways of sharpening or replacing the blade. Moreover, the use of proper grease should be applied to the moveable parts of the pipe cutters like the screws and rollers to decrease wear and the lubrication of the parts during machine use.

It is advisable to store the cutter in dry and clean places to shield it from moisture, which may cause rust. To further protect the tool, a case or cover may also be used. Incorporating these habits into one’s daily work routine will drastically increase the cutter’s life and efficiency in performing various tasks.

Replacing Cutting Wheels and Blades

Steel pipe cutters, for example, have wheels or blades that are subject to wear and/or even chips that need to be energetically replaced, reducing their performance and efficiency. The first step is to consult the user’s manual to understand the kind of cutting wheel or blades that can go with their equipment. Most modern cutting tools use either screw mechanisms or snap fixtures for easy and quick replacement.

Shut off the tool, ensure it is unplugged from the power source (including battery), and cease operation by introducing the battery or wiring into the unit, for many other steps. Press the proper wrench or other accessory added to the clipper to break the retention mechanism. Remove the cut-off wheel in the same manner, more carefully this time, and if it is razor-edged or thin, use protective gloves. Clean the bearing seat and make sure no smudge or damage impacts the reassembly, as this ensures correct engagement and alignment during reassembly.

Place the wheel or blade into the spindle and rotate, making sure that it fits with the respective grooves or holes. After that, tighten all fasteners with balance so as not to have unnecessary shaking during use. Experts advise buying only approved and hard-wearing parts made by the manufacturer, as they fit most of the time.

Finally, carry out testing on the cutter in a semi-real but safe condition after the replacement to check if it was implemented correctly and if the cutter is functioning as well. If followed to the letter, these steps not only help maintain the optimal performance of your cutting tool but also increase its working period, which saves time and money.

Storage Tips for Longevity

- Clean the Tool Before Storage: A brisk wipe-down with a soft rag removes chips and coolant; skipping this step invites rust to settle into every crack.

- Use Protective Covers: A snug case or even a simple slip of oiled cloth acts like armor, blocking dust, moisture, and the surprise nicks that pop up in transit.

- Maintain a Dry Environment: A dark, climate-controlled cabinet holds steady at room temperature, starving damp air of the chance to creep onto metal surfaces.

- Lubricate Moving Parts: A dab of quality grease on gears and slides keeps them ready; a tool that sits dry for months rewards only those who remember to oil.

- Organize Properly: Hanging brackets or a foam-lined drawer cradle the tool without crowding it, guarding cutting edges from bruises that pile up in storage.

Comparative Analysis of Top Models

Heavy-Duty vs. Portable Pipe Cutters

|

Parameter |

Heavy-Duty |

Portable |

|---|---|---|

|

Weight |

Heavy |

Lightweight |

|

Material |

Thick pipes |

Thin pipes |

|

Portability |

Low |

High |

|

Durability |

High |

Moderate |

|

Cutting Power |

High |

Moderate |

|

Usage |

Industrial |

DIY/Small tasks |

|

Cost |

Higher |

Lower |

|

Precision |

High |

Moderate |

Features of High-Performance Cutters

- Superior Cutting Accuracy: Known for its sharp edge and delivery when it comes to cuts, there is minimal wastage of the material to be cut.

- Enhanced Durability: They are crafted from high-stress materials, which makes them resistant to wearing out or losing shape for a long time.

- Ergonomic Design: It is specially designed to be comfortable to hold in the hand. The handles are covered with anti-slip material, and the product has a nice balance to reduce the user’s fatigue during usage.

- Adjustable Cutting Capacity: They work in different modes to assist in cutting steel pipe cutters and other tubes of various sizes and materials.

- High Cutting Efficiency: It uses even the latest cutting tools, such as blades or cutter wheels, which exert minimal forces during material cutting processes, unlike before, thereby enhancing efficiency.

Price Range and Value Comparison

The cost of steel pipe cutters varies depending on the type of user and the budget available. Simple and basic tools can be purchased for as little as $10 to $20. Handheld tools are generally less expensive than other options and are made for occasional or light-duty use. Most pipe cutters fall within the range of $30 to $70; however, more expensive models include higher quality and more comfortable handles. These are ideal for professionals with several tools but do not need all the extreme features of the expensive ones. For industries and professionals where the tools must be used frequently, high-end pipe cutters worth $100 up to $300 are designed for sale, or even more. These cutting machines are usually more expensive as they have more sophisticated cutting mechanisms, better materials such as hardened steel, and additional functionalities such as quick mate systems or multi-purpose multiple pipe cutting.

In terms of pricing and value for money, the beginning or entry level category will always be more attractive to the “do it yourself “ and those who do not often need such gadgets, while the mid level stands for those category that possesses the balance of strength, performance and affordability for the majority of jobs. Durable and precise high-end cutters will be required by experts whose cutting activities do not allow them to relax even a little bit. Finally, let us note that in the process of choosing what cutting tool to choose, the specific conditions and tasks of a user should be clearly outlined, and the prospects of usage as compared to the cost to be incurred should be considered, often in the context of a case that comes with diverse tools.

Frequently Asked Questions (FAQs)

Q: What is a tube cutter, and how does it work?

A: In simple terms, a tube cutter is a cutting tool designed to cut all types of tubing, including metal and plastic. It is usually round with a small, sharp wheel that goes around the tube and cuts through it after a few seconds. Such a tool is helpful in events where extreme precision is needed, such as plumbing and HVAC jobs.

Q: How do I choose the right tubing cutter for my project?

A: When choosing a tube Cutter, the first thing to consider is the material to be cut. It could be copper, PVC, stainless steel, or galvanized steel. The second consideration is the pipe or tubing size, and the last is the cutting capacity you need for your project. Furthermore, factors supporting ease of use, such as ergonomic handles and ratchet functionality for enhanced cutting rates during the operation, are also preferred.

Q: What are hinged pipe cutters, and when should I use them?

A: Hinged pipe cutters are tools for cutting large-diameter pipes and tubes. Instead of wrestling with complex and unwieldy cutting materials, they feature a hinge that allows them to pivot, allowing for easier working and cutting in almost any location. This cutter type is beneficial for heavy-duty work requiring precise cuts using simple implements.

Q: Can I use a tubing cutter for plastic pipe?

A: A tubing cutter can also be used to cut plastic pipes. Many cutters are manufactured with fixed cutting diameters and depth lengths so that plumbers and other tradesmen can use them on polyvinyl chloride (PVC) or any other type of plastic manhole. The specification will state what thickness the tool can cut before needing to be sharpened or changed.

Q: What is the cutting capacity of steel pipe cutters?

A: The cutting capacity of different steel pipe cutters varies, but some can even easily cut pipes with a 4-inch diameter. Ensure that the adverse cases with the pipe cutter you plan to use are acceptable to your project.

Q: Are electric pipe cutters available for heavy-duty applications?

A: Electric pipe cutters are also available for heavy applications. Such automatic/electric devices can be great for jobs that require solid throughput and a sense of urgency. This also includes extensive tasks that involve the use of hand pipe-cutting tools.

Q: How do I maintain my steel pipe cutter for optimal performance?

A: To keep your steel pipe cutter in top working order, it is essential to clean and sharpen the cutting wheel regularly. The blade should be cleaned or wiped so that no dirt or debris is left on it. The moving parts should be lubricated, and the tool should undergo thorough inspection for any damage or signs of wear that may reduce its performance. Moisture–sensitive tools benefit from being kept in a dry area.

Q: What accessories can enhance the use of my tubing cutter?

A: Tubing cutters can improve functionality through spares like cutting wheels, cases, or additional handles. A cutting guide is also valuable in correctly making cuts, particularly when working with longer straight pipe sections.

Q: Is a ratchet pipe cutter more efficient than a manual cutter?

A: A ratchet pipe cutter is generally more efficacious than a manual pipe cutter. It facilitates more seamless and faster cutting with less energy expended, making it better suited for use in multiple installations and projects that may have more robust materials.

Q: What are the benefits of using a cordless pipe cutter?

A: Cordless pipe cutters offer portability and convenience in general. They reduce the chaos of cross lines and facilitate distant operational sites with no electrical sockets. Many also maintain speed easily; hence, they can work in DIY settings requiring professionalism.

Reference Sources

Pipe Wrenches – Procedures Academy – NC State ISE – This page from North Carolina State University gives an overview of the different kinds of hand tools using pipe cutters with the emphasis on their uses in application.