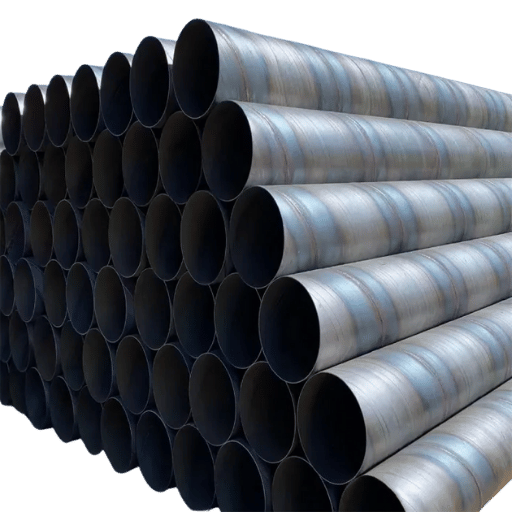

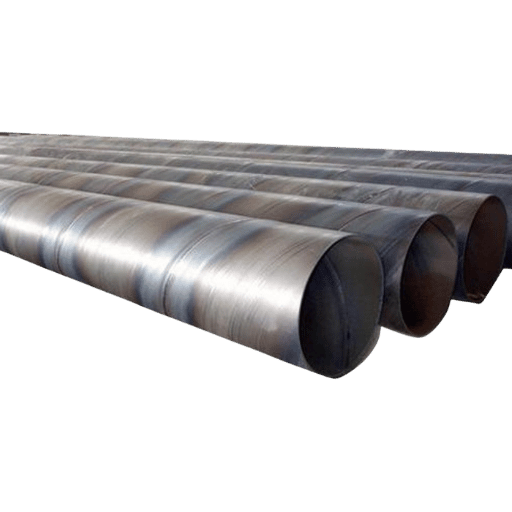

Spiral-welded pipes are widely used in various industries due to their versatility and strength in today’s rapidly evolving industrial landscape. Unique manufacturing processes, characterized by the use of a spiral steel coil and seam welding, make these pipes essential for many structural and infrastructural projects. For fluid transportation or any structural use, spiral-welded pipes are among the best solutions provided by the steel pipe industry, designed to meet stringent specifications and quality standards.

Introduction to Spiral Welded Pipes

What are Spiral Welded Pipes?

Spiral-welded pipes are welded steel pipes with helical seams made from a continuous coil of steel. The welds are made through double submerged arc welding, which produces strong welds to withstand high pressures. These pipes usually come in large diameters and thus find a broad range of applications. Their construction allows for considerable flexibility in wall thickness and length, enabling them to meet different specifications in industrial and structural applications.

Importance of Spiral Welded Pipes in Industry

Spiral-welded pipes have an essential value in industries such as the oil and gas industry, water transportation, and construction, due to their durability and competitive prices.

They are essential in projects where resistance to high pressure and structural integrity are paramount. Additionally, the fabrication process ensures that these pipes conform to stringent standards, which solidifies their place in critical infrastructure projects.

Applications of Spiral Welded Pipes

The applications of spiral-welded pipes come in various forms across multiple industries. In the oil and gas sector, they serve as pipeline systems to transport oil and gas over long distances. Construction projects for water supply include casing pipe and pipe piling, among other applications. Their seamless construction and rugged design make them suitable for structural steel applications for bridges and buildings. Furthermore, with improvements in their manufacturing processes, such as galvanization and quality control measures, their ability to last and remain dependable in various environments has been dramatically enhanced.

Top 15 Spiral Welded Pipe Manufacturers

1. Baling Steel

Year Founded: 1998

Introduction: A leading manufacturer specializing in high-quality spiral welded pipes for various industrial applications.

Main Products: Spiral welded pipes, structural steel pipes, and custom steel solutions.

Key Advantages: High-quality manufacturing standards, extensive customization options, and a strong reputation in the industry.

Website: Baling Steel

2. Nucor Skyline

Year Founded: 2003

Introduction: A prominent North American manufacturer with expertise in steel foundation products.

Main Products: Spiralweld pipes, pipe piling, and structural sections.

Key Advantages: Custom fabrication, large diameter options, and compliance with seismic standards.

Website: Nucor Skyline

3. Tianjin Youfa Steel Pipe Group

Year Founded: 1975

Introduction: One of the largest welded pipe manufacturers globally, based in China.

Main Products: Spiral welded pipes, galvanized pipes, and square/rectangular pipes.

Key Advantages: Extensive product range, global scale, and integrated supply chain.

Website: Youfa Steel

4. American SpiralWeld Pipe Company

Year Founded: 1905

Introduction: A major U.S. manufacturer specializing in large-diameter spiral-welded pipes (Subsidiary of American Cast Iron Pipe Company).

Main Products: Spiral-welded steel pipes, ductile iron pipes, and fire hydrants.

Key Advantages: Expertise in large-diameter pipes and infrastructure projects.

Website: American SpiralWeld

5. Naylor Pipe Company

Year Founded: 1983

Introduction: A U.S.-based manufacturer known for its spiral buttweld pipes.

Main Products: Spiral buttweld pipes for industrial and structural applications.

Key Advantages: Uniform wall thickness, accurate diameter, and cost-effective solutions.

Website: Naylor Pipe

6. Metal Zenith

Year Founded: 1967

Introduction: A premium steel manufacturing company with a global reach.

Main Products: High-strength steel coils and spiral pipes.

Key Advantages: Advanced quality control and customization capabilities.

Website: Metal Zenith

7. Gnee Steel

Year Founded: 1984

Introduction: A Chinese manufacturer offering a wide range of steel products.

Main Products: API 5L spiral welded pipes, carbon steel pipes, and fittings.

Key Advantages: High-quality materials, cost-effective solutions, and extensive inventory.

Website: Gnee Steel

8. Spiral Manufacturing Co., Inc.

Year Founded: 1962

Introduction: A U.S.-based specialist in spiral pipe production.

Main Products: Spiral pipes for industrial and high-pressure applications.

Key Advantages: Decades of expertise and high precision in manufacturing.

Website: Spiral Manufacturing

9. Turner Industries Group, LLC

Year Founded: 1970

Introduction: A U.S. industrial services company with a focus on pipe fabrication.

Main Products: Carbon and alloy pipes for construction and infrastructure.

Key Advantages: Large-scale fabrication and innovative techniques.

Website: Turner Industries

10. Metallica

Year Founded: 1975

Introduction: An Indian manufacturer with a broad portfolio of piping solutions.

Main Products: SSAW pipes, seamless pipes, and fittings.

Key Advantages: Versatility and long-standing market presence.

Website: Metallica

11. Industrial Tube and Steel Corporation

Year Founded: 1956

Introduction: A Midwest U.S. supplier of steel tubing and cast iron products.

Main Products: Seamless and welded carbon steel pipes.

Key Advantages: Large inventory and regional expertise.

Website: Industrial Tube and Steel

12. Metal Works Corporation

Year Founded: 1958

Introduction: A custom manufacturer specializing in spiral pipe solutions.

Main Products: Custom spiral pipes and value-added services.

Key Advantages: Deep customization capabilities and material diversity.

Website: Metal Works

13. The Tin Knockers Industrial

Year Founded: 1967

Introduction: A niche manufacturer for specialized industrial applications.

Main Products: Spiral buttweld and lock seam pipes.

Key Advantages: Expertise in abrasion and corrosion-resistant pipes.

Website: Tin Knockers

14. Marstan, Inc.

Year Founded: 1985

Introduction: A U.S.-based specialist in spiral pipe and fittings.

Main Products: Spiral ductwork and piping.

Key Advantages: High customer satisfaction and product reliability.

Website: Marstan

15. API Steel Pipe

Year Founded: 1993

Introduction: A manufacturer specializing in API 5L standard pipes.

Main Products: Spiral welded pipes for oil and gas industries.

Key Advantages: High strength and versatility in applications.

Website: API Steel Pipe

⚠️ Industry Challenges Facing Spiral Welded Pipe Manufacturers

💼 Market Competition and Pricing Pressure

The spiral-welded pipe manufacturing industry faces stiff competition and pricing pressure. Manufacturers seek methods of offering competitive prices while providing the necessary quality considerations demanded by the client. The spiral-welded pipe market comprises lots of suppliers who compete for significant projects in the oil and gas, water, and construction sectors. Manufacturers must therefore ensure superior efficiency in the production process, saving costs through the adoption of advanced technologies, such as spiral buttweld and submerged arc welding, among others. Manufacturers must innovate, strategize their pricing, and manage the intangibility of market share in a fiercely competitive environment.

🏭 Raw Material Sourcing and Supply Chain Issues

Spiral-welded pipe producers confront yet another set of challenges related to raw material sourcing and the supply chain. The production of high-quality welded steel pipes requires a consistent supply of carbon steel, alloys, and other materials. Disruptions in the supply chain can delay manufacturers, increase costs, or put manufacturers at odds with natural disasters and geopolitical tensions. Hence, manufacturers should establish robust supplier networks and diversify their sourcing strategies, along with contingency plans for any weaknesses in sourcing raw materials. Changes in the prices of raw materials affect the final cost of pipe production, prompting manufacturers to adopt a flexible pricing strategy and refine their inventory management systems to strike a balance between profitability and meeting specifications and industry standards.

⚙️ Technological Advancements and Adaptation

Technology advancement and adaptation, in general, keep spiral-welded pipe manufacturers at the forefront of competition. Incorporating new-age technologies into manufacturing serves as a force multiplier, ensuring greater precision and efficiency in pipe production. Automated quality control systems and double-submerged arc welding techniques are part of this new generation. Furthermore, manufacturers must invest heavily in research and development to innovate and adapt to new technologies that can enhance the performance of both their spiral-weld pipes and the structural steel applications they utilize. Embracing a technological approach would grant manufacturers increased operational efficiency while leaving them open to fulfilling growing demands for larger diameter pipes, customized specifications, and sustainable practices.

🚀 Emerging Technologies in Spiral Welded Pipe Production

🤖 Automation and Smart Manufacturing

The marriage of automation and smart manufacturing has brought revolutionary changes to the spiral-welded pipe production process. Using modern technological developments, robotics, and AI enables manufacturers to enhance the welding process for greater accuracy and efficiency, thereby reducing human error and increasing output. The automation process can also monitor in real-time or make adjustments during the production of spiral-weld pipes, ensuring quality is assured throughout. Smart manufacturing also manages resources efficiently, thereby providing the best use of materials (e.g., carbon steel, alloys) and minimizing waste.

⚡ Innovations in Welding Techniques

The advancements in welding technology have significantly improved the quality and durability of spiral-welded pipes. New and advanced welding procedures have been developed, utilizing double submerged arc welding and spiral buttweld techniques, to produce high-strength weld seams that can withstand the highest pressures and environmental effects with ease. The wall thickness and weld integrity can be controlled using these techniques, which are critically essential for satisfying both ASTM and API requirements. As these techniques continue to develop, manufacturers will be able to produce larger-diameter pipes with sound structural integrity for various applications.

🌐 Impact of Industry 4.0 on Pipe Manufacturing

Industry 4.0 is perceived as a transformative force in pipe manufacturing, imparting digitalization and connectivity into manufacturing processes. IoT and data analytics enable manufacturers to gain insight into every step of pipe production, from coil fabrication to quality control. This connectivity then enables the preventive maintenance of the machinery while simultaneously optimizing the manufacturing line; such measures decrease downtime and increase productivity. Thus, spiral-welded pipe manufacturers produce high-quality products efficiently and flexibly to meet the demands of customized and environmentally friendly pipe solutions.

🌱 Sustainability Practices in the Pipe Manufacturing Industry

♻️ Recycling and Waste Management Strategies

Recycling and waste management strategies are sustainability practices that spiral-welded pipe manufacturers have adopted to minimize their environmental impact. Steel and metals in a recycled form are used by companies in their manufacturing processes with the ultimate goal of saving on virgin materials and conserving natural resources. In these industries, proficient waste management systems aim to handle scrap materials and by-products, taking responsibility for their own recycling. These practices serve the dual role of caring for the environment and saving on probable costs, as recycled materials are often cheaper than newly sourced raw materials.

⚡ Energy Efficiency in Production Processes

Energy efficiency remains a buzzword among pipe manufacturers, as they strive to reduce carbon emissions and lower operational costs. Production innovations, such as energy-efficient welding techniques and automation systems, help reduce energy consumption. Energy management and production equipment optimization enable manufacturers further to limit energy use in the production of spiral-welded pipes. Energy efficiency is a key focus of the global call for sustainable development, offering a competitive advantage to manufacturers of eco-friendly steel products.

📋 Environmental Compliance and Regulations

Given the need for environmental compliance and regulation, the commitment to sustainability is evident in the setup of spiral-welded pipes. The manufacturer must comply with a range of local and international laws governing emissions, waste disposal, and resource usage. Products are made to comply with ASTM standards and meet environmental requirements, while maintaining high quality. With respect for these national regulations applied to environmental protection, manufacturers safeguard the environment and hence slowly destroy risk acknowledgment from non-complianc,e such as fines and litigation.

📈 Conclusion

The making of spiral-welded pipes is an ever-changing production line; technological improvements and sustainability efforts drive it. The top 15 manufacturers portrayed above are the pioneers defining this sector, each with its own unique characteristics and capabilities to satisfy the growing demand of the variety of modern industrial applications. The spiral-welded pipe industry faces challenges in competition, supply chain management, and environmental compliance; however, the above manufacturers will be well-equipped to adapt and succeed in the fluid market setting of the year 2025 and beyond.