Drill Pipe

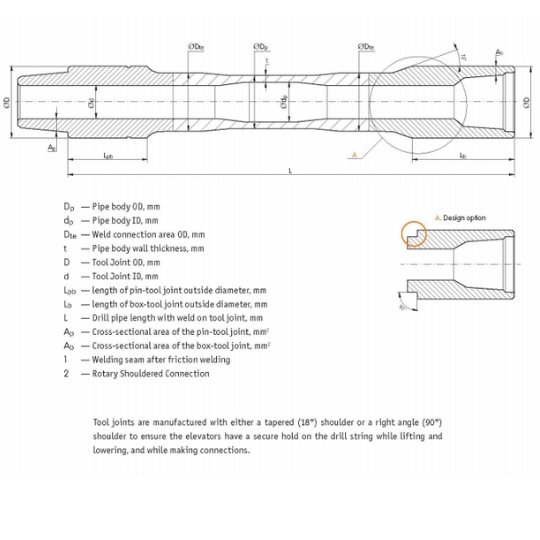

Drill Pipe Is A Major Player In Oil Extraction, And It Is Highly Resistant To Abrasion, Corrosion And Torque. The Normal Diameter Of the Drill Pipe Is 2^6 Inches And The Common Length Is About 9 Meters.

Balingsteel Can Produce High-Quality Drill Pipe In Accordance With API SPEC 5D, API SPEC 7-1, ISO 11960, And NACE MR0175.

Recommended Products By Balingsteel

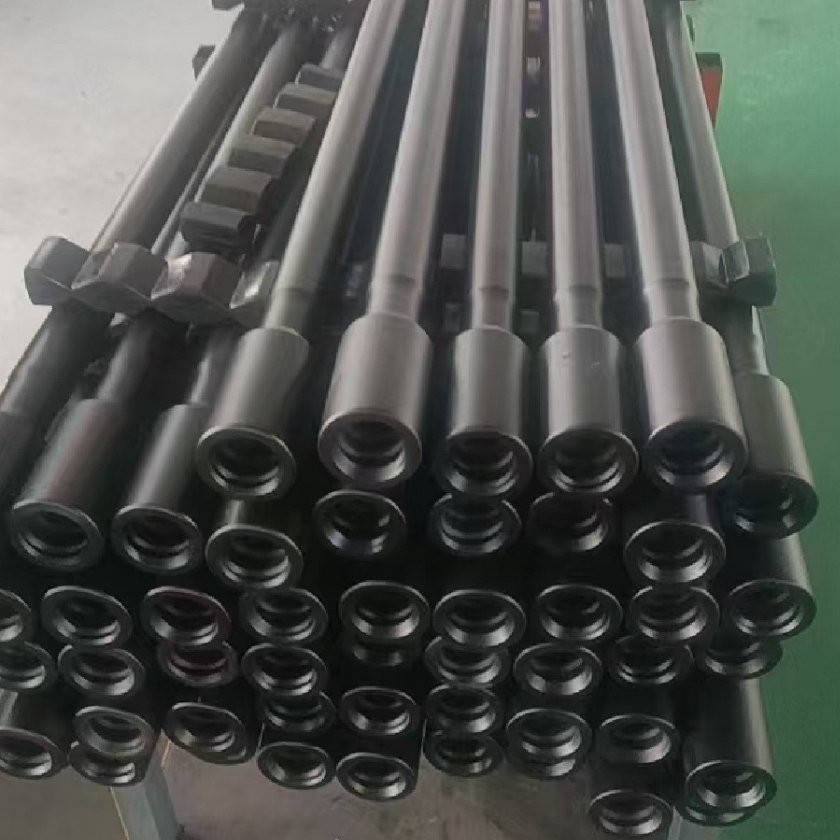

High Quality Drill Pipes

Balingsteel Offers You High-Quality Drill Pipes with the Following Advantages:

- High-Quality Raw Materials: We Will Purchase High-Quality Steel Raw Materials with Strong Impact and Metal Fatigue Resistance While Using Sophisticated Processing Methods to Improve the Stability of the Finished Product.

- Standardized Management: Combined with AI Digital Management, From Raw Materials to Production and Finally to the Finished Product, To Achieve Real-Time Control and Information Processing.

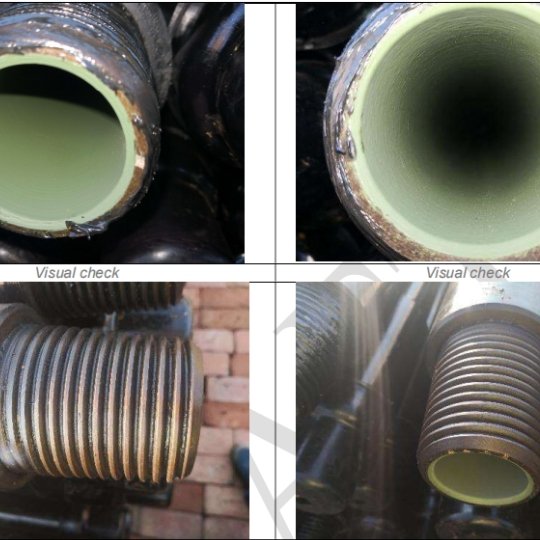

- Strict Inspection and Extra Service: We Will Strictly Inspect the Raw Materials, Finished Pipe Body, Pipe Ends, Joints and Welds. At the Same Time, We Provide You with Additional Services Such as Internal Coating and Customized Packaging.

Wide Range of Drill Pipe

Balingsteel Can Offer a Wide Range of Drill Pipes for Your Project as Follows:

- OD:2 3/8″,2 7/8″,3 1/2″,4″,4 1/2″,5″,5 1/2″,5 7/8″,6 5/8″,7 5/8″,8 5/8″

- Standards: API Spec 5DP, ISO 11961

- Apply: Premium Connection, Super High-Strength, Non-slip-Crush, Slip-Protected, Flush Hole, Double-Walled, Arctic Service, Landing String, Sour Service and Heavy Weight Drill Pipe.

If You Are Still Looking for Drill Pipe Suppliers, Please Feel Free to Contact Us!

Type of Drill Pipe

According to the Degree of Use of the Product, Balingsteel Categorizes Drill Pipes into the Following Three Types:

- N-Class Pipe (New Pipe): These Pipes Are New and Unused and Have the Best Performance. However, They Tend to Be the Most Expensive.

- P-Class Pipe (Premium Pipe): These Are Pipes That Have Been Used for Some Time and Can Be Interpreted as 90% New Drill Pipe. It Is the Most Cost-Effective and Frequently Used Product.

- C-Class Pipe (Used Pipe): This Is the Lowest Grade of Drill Pipe and Is Subdivided into C-1, C-2, And C-3 Grades. It Can Only Be Used in Some Easy Environments and It Is Very Cheap.

Data Sheet

- Heavy Weight Drill Pipes Data

- Drill Pipes Data

- Sour Service Drill Pipes Data

- Drill Collars Data

- Connection Mechanical Characteristics

Table B.3 Heavy Weight Drill Pipes Data |

|||||||||

| Size | Pipe Body OD |

Pipe Body ID |

Central Upset OD |

Elevator Upset OD |

RSC Type | RSC Bevel Dia. |

Tool Joint OD |

Tool Joint ID |

Drift Size |

| OD | ID | Dc | Dte | Df | D | d | |||

| in | in | in | in | in | in | in | in | in | |

| 3 1/2 | 3 1/2 | 2 1/4 | 4.000 | 3.875 | NC38 | 4.578 | 4 3/4 | 2 1/4 | 2.000 |

| 3 1/2 | 3 1/2 | 2 1/16 | 4.000 | 3.875 | NC38 | 4.578 | 5 | 2 1/16 | 1.813 |

| 3 1/2 | 3 1/2 | 2 | 4.000 | 3.638 | BLIDS®31 | 3.953 | 4 1/8 | 2 | 1.750 |

| 3 1/2 | 3 1/2 | 2 1/16 | 4.000 | 3.638 | BLST®31 | 3.906 | 4 1/8 | 2 1/16 | 1.813 |

| 3 1/2 | 3 1/2 | 2 1/4 | 4.000 | 3.875 | BLIDS®38 | 4.578 | 4 3/4 | 2 1/4 | 2.000 |

| 3 1/2 | 3 1/2 | 2 1/4 | 4.000 | 3.875 | BLMT®38 | 4.578 | 4 3/4 | 2 1/4 | 2.000 |

| 4 | 4 | 2 9/16 | 4.500 | 4.188 | NC40 | 5.016 | 5 1/4 | 2 9/16 | 2.313 |

| 4 | 4 | 2 9/16 | 4.500 | 4.188 | BLIDS®40 | 5.016 | 5 1/4 | 2 9/16 | 2.313 |

| 4 | 4 | 2 9/16 | 4.500 | 4.188 | BLMT®40 | 4.875 | 5 1/4 | 2 9/16 | 2.313 |

| 4 | 4 | 2 9/16 | 4.500 | 4.188 | BLST®39 | 4.772 | 4 7/8 | 2 9/16 | 2.313 |

| 4 | 4 | 2 9/16 | 4.500 | 4.188 | BLIST®39 | 4.786 | 4 7/8 | 2 9/16 | 2.313 |

| 4 1/2 | 4 1/2 | 2 11/16 | 5.000 | 4.688 | NC46 | 5.719 | 6 1/4 | 2 11/16 | 2.438 |

| 4 1/2 | 4 1/2 | 2 11/16 | 5.000 | 4.688 | BLIDS®40 | 5.016 | 5 1/4 | 2 11/16 | 2.438 |

| 4 1/2 | 4 1/2 | 2 11/16 | 5.000 | 4.688 | BLST®40 | 5.063 | 5 1/4 | 2 11/16 | 2.438 |

| 5 | 5 | 3 | 5.500 | 5.125 | NC50 | 6.063 | 6 5/8 | 3 | 2.750 |

| 5 | 5 | 3 | 5.500 | 5.125 | BLIDS®50 | 6.063 | 6 5/8 | 3 | 2.750 |

| 5 1/2 | 5 1/2 | 4 | 6.000 | 5.688 | 5-1/2FH | 6.719 | 7 | 4 | 3.750 |

| 5 1/2 | 5 1/2 | 3 1/4 | 6.000 | 5.688 | 5-1/2FH | 6.719 | 7 | 3 1/4 | 3.000 |

| 5 1/2 | 5 1/2 | 3 1/4 | 6.000 | 5.688 | BLIST®50 | 6.318 | 6 1/2 | 3 1/4 | 3.000 |

| 5 1/2 | 5 1/2 | 3 1/4 | 6.000 | 5.688 | BLIDS®5-1/2FH | 6.719 | 7 | 3 1/4 | 3.000 |

| 5 1/2 | 5 1/2 | 4 | 6.000 | 5.688 | BLST®54 | 6.472 | 6 3/4 | 4 | 3.750 |

| 5 1/2 | 5 1/2 | 4 | 6.000 | 5.688 | BLIST®54 | 6.469 | 6 5/8 | 4 | 3.750 |

| 5 7/8 | 5 7/8 | 4 | 6.375 | 6.000 | BLIDS®5-1/2FH | 6.719 | 7 1/4 | 4 | 3.750 |

| 5 7/8 | 5 7/8 | 4 1/8 | 6.375 | 6.000 | BLST®57 | 6.764 | 7 | 4 1/8 | 3.875 |

| 5 7/8 | 5 7/8 | 4 1/4 | 6.375 | 6.000 | BLIST®57 | 6.721 | 7 | 4 1/4 | 4.000 |

| 6 5/8 | 6 5/8 | 4 1/2 | 7.125 | 6.938 | 6-5/8FH | 7.703 | 8 1/4 | 4 1/2 | 4.250 |

| 6 5/8 | 6 5/8 | 5 | 7.125 | 6.938 | 6-5/8FH | 7.703 | 8 | 5 | 4.750 |

| 6 5/8 | 6 5/8 | 5 | 7.125 | 6.937 | BLIDS®6-5/8 | 7.703 | 8 | 5 | 4.750 |

Table B.1 Drill Pipes Data |

||||||

| Pipe Body OD | Nominal Weight | Upset Type | Grade | RSC Type | Tool Joint | |

| (in) | (lb/ft) | OD (in) | ID (in) | |||

| 2 3/8 | 6.65 | EU | E / X / G | NC26 | 3 3/8 | 1 3/4 |

| 2 3/8 | 6.65 | EU | G / S / Z / V | BLIDS®26 | 3 3/8 | 1 3/4 |

| 2 3/8 | 6.65 | EU | S / Z / V | BLST®26 | 3 3/8 | 1 3/4 |

| 2 3/8 | 6.65 | IU | G / S | BLIDS®23 | 3 | 1 3/8 |

| 2 3/8 | 6.65 | IU | G / S | BLMT®2-3/8PAC | 2 7/8 | 1 3/8 |

| 2 7/8 | 10.40 | EU | E | NC31 | 4 1/8 | 2 1/8 |

| 2 7/8 | 10.40 | EU | X / G | NC31 | 4 1/8 | 2 |

| 2 7/8 | 10.40 | EU | S | NC31 | 4 3/8 | 1 5/8 |

| 2 7/8 | 10.40 | EU | G / S / Z / V | BLIDS®31 | 4 1/8 | 2 |

| 2 7/8 | 10.40 | EU | G / S / Z / V | BLST®31 | 4 1/8 | 2 |

| 2 7/8 | 10.40 | IU | E / X / G | BLIDS®26 | 3 3/8 | 1 3/4 |

| 2 7/8 | 10.40 | IU | E / X / G | BLMT®2-7/8PAC | 3 1/8 | 1 1/2 |

| 2 7/8 | 10.40 | IU | E / X / G | BLST®26 | 3 3/8 | 1 3/4 |

| 3 1/2 | 13.30 | EU | E | NC38 | 4 3/4 | 2 11/16 |

| 3 1/2 | 13.30 | EU | X | NC38 | 5 | 2 9/16 |

| 3 1/2 | 13.30 | EU | G | NC38 | 5 | 2 7/16 |

| 3 1/2 | 13.30 | EU | S | NC38 | 5 | 2 1/8 |

| 3 1/2 | 13.30 | EU | G | BLIDS®38 | 5 | 2 9/16 |

| 3 1/2 | 13.30 | EU | S / Z | BLIDS®38 | 5 | 2 7/16 |

| 3 1/2 | 13.30 | EU | V | BLIDS®38 | 5 | 2 1/8 |

| 3 1/2 | 13.30 | EU | G | BLMT®38 | 4 3/4 | 2 11/16 |

| 3 1/2 | 13.30 | EU | S / Z / V | BLMT®38 | 4 3/4 | 2 9/16 |

| 3 1/2 | 13.30 | EU | G | BLST®36 | 4 3/4 | 2 7/16 |

| 3 1/2 | 13.30 | EU | S / Z / V | BLST®36 | 4 3/4 | 2 1/8 |

| 3 1/2 | 13.30 | EU | G | BLST®39 | 4 7/8 | 2 13/16 |

| 3 1/2 | 13.30 | EU | S | BLST®39 | 4 7/8 | 2 11/16 |

| 3 1/2 | 13.30 | EU | Z / V | BLST®39 | 5 | 2 9/16 |

| 3 1/2 | 13.30 | EU | G | BLIST®38 | 4 3/4 | 2 11/16 |

| 3 1/2 | 13.30 | EU | S / Z / V | BLIST®38 | 4 3/4 | 2 9/16 |

| 3 1/2 | 13.30 | EU | G / S / Z / V | BLIST®39 | 4 7/8 | 2 11/16 |

| 3 1/2 | 13.30 | IU | E / X / G | BLIDS®31 | 4 1/8 | 2 |

| 3 1/2 | 13.30 | IU | S | BLIDS®31 | 4 1/4 | 2 |

| 3 1/2 | 13.30 | IU | E | BLST®31 | 4 | 2 1/4 |

| 3 1/2 | 13.30 | IU | X / G / S | BLST®31 | 4 1/8 | 2 |

| 3 1/2 | 15.50 | EU | E | NC38 | 5 | 2 9/16 |

| 3 1/2 | 15.50 | EU | X | NC38 | 5 | 2 7/16 |

| 3 1/2 | 15.50 | EU | G | NC38 | 5 | 2 1/8 |

| 3 1/2 | 15.50 | EU | S | NC40 | 5 1/2 | 2 1/4 |

| 3 1/2 | 15.50 | EU | E / X | BLIDS®38 | 5 | 2 9/16 |

| 3 1/2 | 15.50 | EU | G | BLIDS®38 | 5 | 2 7/16 |

| 3 1/2 | 15.50 | EU | S / Z / V | BLIDS®38 | 5 | 2 1/8 |

| 3 1/2 | 15.50 | EU | G | BLMT®38 | 4 3/4 | 2 9/16 |

| 3 1/2 | 15.50 | EU | S / Z | BLMT®38 | 4 7/8 | 2 7/16 |

| 3 1/2 | 15.50 | EU | V | BLMT®38 | 5 | 2 1/4 |

| 3 1/2 | 15.50 | EU | X | BLST®36 | 4 3/4 | 2 9/16 |

| 3 1/2 | 15.50 | EU | G | BLST®36 | 4 3/4 | 2 7/16 |

| 3 1/2 | 15.50 | EU | S / Z / V | BLST®36 | 4 3/4 | 2 1/8 |

| 3 1/2 | 15.50 | EU | G / S | BLST®39 | 5 | 2 9/16 |

| 3 1/2 | 15.50 | EU | Z / V | BLST®39 | 5 | 2 7/16 |

| 3 1/2 | 15.50 | EU | G | BLIST®38 | 4 3/4 | 2 9/16 |

| 3 1/2 | 15.50 | EU | S / Z / V | BLIST®38 | 4 3/4 | 2 7/16 |

| 3 1/2 | 15.50 | EU | G / S / Z / V | BLIST®39 | 4 7/8 | 2 9/16 |

| 4 | 14.00 | IU | E | NC40 | 5 1/4 | 2 13/16 |

| 4 | 14.00 | IU | X | NC40 | 5 1/4 | 2 11/16 |

| 4 | 14.00 | IU | G | NC40 | 5 1/2 | 2 7/16 |

| 4 | 14.00 | IU | S | NC40 | 5 1/2 | 2 |

| 4 | 14.00 | IU | E / X | BLIDS®38 | 5 | 2 11/16 |

| 4 | 14.00 | IU | G | BLIDS®38 | 5 | 2 9/16 |

| 4 | 14.00 | IU | S | BLIDS®38 | 5 | 2 7/16 |

| 4 | 14.00 | IU | E / X | BLIDS®40 | 5 1/4 | 2 13/16 |

| 4 | 14.00 | IU | G | BLIDS®40 | 5 1/4 | 2 11/16 |

| 4 | 14.00 | IU | S / Z / V | BLIDS®40 | 5 1/4 | 2 9/16 |

| 4 | 14.00 | IU | G | BLMT®38 | 5 | 2 9/16 |

| 4 | 14.00 | IU | S | BLMT®38 | 5 | 2 7/16 |

| 4 | 14.00 | IU | G | BLMT®40 | 5 1/4 | 2 11/16 |

| 4 | 14.00 | IU | S / Z / V | BLMT®40 | 5 1/4 | 2 9/16 |

| 4 | 14.00 | IU | E / X | BLST®36 | 4 3/4 | 2 9/16 |

| 4 | 14.00 | IU | G | BLST®36 | 4 3/4 | 2 7/16 |

| 4 | 14.00 | IU | S | BLST®36 | 4 3/4 | 2 1/8 |

| 4 | 14.00 | IU | E / X | BLST®39 | 4 7/8 | 2 13/16 |

| 4 | 14.00 | IU | G | BLST®39 | 4 7/8 | 2 11/16 |

| 4 | 14.00 | IU | S | BLST®39 | 4 7/8 | 2 9/16 |

| 4 | 14.00 | IU | Z / V | BLST®39 | 5 | 2 9/16 |

| 4 | 14.00 | IU | G | BLIST®38 | 4 3/4 | 2 9/16 |

| 4 | 14.00 | IU | S | BLIST®38 | 4 3/4 | 2 7/16 |

| 4 | 14.00 | IU | G | BLIST®39 | 4 7/8 | 2 11/16 |

| 4 | 14.00 | IU | S / Z / V | BLIST®39 | 4 7/8 | 2 9/16 |

| 4 | 15.70 | IU | E / X | BLIDS®40 | 5 1/4 | 2 13/16 |

| 4 | 15.70 | IU | G | BLIDS®40 | 5 1/4 | 2 11/16 |

| 4 | 15.70 | IU | S | BLIDS®40 | 5 1/4 | 2 9/16 |

| 4 | 15.70 | IU | Z / V | BLIDS®40 | 5 1/2 | 2 7/16 |

| 4 | 15.70 | IU | G | BLMT®40 | 5 1/4 | 2 11/16 |

| 4 | 15.70 | IU | S / Z | BLMT®40 | 5 1/4 | 2 9/16 |

| 4 | 15.70 | IU | V | BLMT®40 | 5 1/4 | 2 7/16 |

| 4 | 15.70 | IU | G | BLST®39 | 4 7/8 | 2 9/16 |

| 4 | 15.70 | IU | S / Z / V | BLST®39 | 5 | 2 7/16 |

| 4 | 15.70 | IU | G / S | BLST®40 | 5 1/4 | 2 11/16 |

| 4 | 15.70 | IU | Z / V | BLST®40 | 5 3/8 | 2 9/16 |

| 4 | 15.70 | IU | G | BLIST®39 | 4 7/8 | 2 9/16 |

| 4 | 15.70 | IU | S / Z / V | BLIST®39 | 5 | 2 7/16 |

| 4 1/2 | 16.60 | IEU | E | NC46 | 6 1/4 | 3 1/4 |

| 4 1/2 | 16.60 | IEU | X / G | NC46 | 6 1/4 | 3 |

| 4 1/2 | 16.60 | IEU | S | NC46 | 6 1/4 | 2 3/4 |

| 4 1/2 | 16.60 | IEU | E / X / G | BLIDS®46 | 6 | 3 1/4 |

| 4 1/2 | 16.60 | IEU | S / Z / V | BLIDS®46 | 6 | 3 |

| 4 1/2 | 16.60 | IEU | G / S / Z / V | BLMT®46 | 6 | 3 1/4 |

| 4 1/2 | 16.60 | IEU | G / S / Z / V | BLST®46 | 6 | 3 1/4 |

| 4 1/2 | 16.60 | IEU | G / S / Z / V | BLIST®46 | 6 | 3 1/4 |

| 4 1/2 | 16.60 | IEU | G | BLIDS®40 | 5 1/4 | 2 11/16 |

| 4 1/2 | 16.60 | IEU | S | BLIDS®40 | 5 1/4 | 2 9/16 |

| 4 1/2 | 16.60 | IEU | G / S | BLST®40 | 5 1/4 | 2 11/16 |

| 4 1/2 | 20.00 | IEU | E | NC46 | 6 1/4 | 3 |

| 4 1/2 | 20.00 | IEU | X | NC46 | 6 1/4 | 2 3/4 |

| 4 1/2 | 20.00 | IEU | G | NC46 | 6 1/4 | 2 1/2 |

| 4 1/2 | 20.00 | IEU | S | NC46 | 6 1/4 | 2 1/4 |

| 4 1/2 | 20.00 | IEU | E / X / G | BLIDS®46 | 6 | 3 |

| 4 1/2 | 20.00 | IEU | S / Z / V | BLIDS®46 | 6 | 2 3/4 |

| 4 1/2 | 20.00 | IEU | G / S / Z / V | BLMT®46 | 6 | 3 |

| 4 1/2 | 20.00 | IEU | G / S / Z / V | BLST®46 | 6 | 3 |

| 4 1/2 | 20.00 | IEU | G / S / Z / V | BLIST®46 | 6 | 3 |

| 5 | 19.50 | IEU | E | NC50 | 6 5/8 | 3 3/4 |

| 5 | 19.50 | IEU | X | NC50 | 6 5/8 | 3 1/2 |

| 5 | 19.50 | IEU | G | NC50 | 6 5/8 | 3 1/4 |

| 5 | 19.50 | IEU | S | NC50 | 6 5/8 | 2 3/4 |

| 5 | 19.50 | IEU | E | BLIDS®50 | 6 1/2 | 3 3/4 |

| 5 | 19.50 | IEU | X | BLIDS®50 | 6 5/8 | 3 3/4 |

| 5 | 19.50 | IEU | G | BLIDS®50 | 6 5/8 | 3 1/2 |

| 5 | 19.50 | IEU | S / Z / V | BLIDS®50 | 6 5/8 | 3 1/4 |

| 5 | 19.50 | IEU | G / S / Z / V | BLMT®50 | 6 5/8 | 3 1/2 |

| 5 | 19.50 | IEU | E / X | BLST®46 | 6 | 3 1/2 |

| 5 | 19.50 | IEU | G | BLST®46 | 6 | 3 1/4 |

| 5 | 19.50 | IEU | S / Z / V | BLST®46 | 6 | 3 |

| 5 | 19.50 | IEU | E / X / G | BLST®52 | 6 1/2 | 4 |

| 5 | 19.50 | IEU | S / Z / V | BLST®52 | 6 1/2 | 3 3/4 |

| 5 | 19.50 | IEU | G / S / Z | BLIST®46 | 6 | 3 1/2 |

| 5 | 19.50 | IEU | S / Z / V | BLIST®46 | 6 1/4 | 3 1/4 |

| 5 | 19.50 | IEU | G | BLIST®50 | 6 1/2 | 4 |

| 5 | 19.50 | IEU | S / Z / V | BLIST®50 | 6 1/2 | 3 3/4 |

| 5 | 25.60 | IEU | E | NC50 | 6 5/8 | 3 1/2 |

| 5 | 25.60 | IEU | X | NC50 | 6 5/8 | 3 |

| 5 | 25.60 | IEU | G | NC50 | 6 5/8 | 2 3/4 |

| 5 | 25.60 | IEU | S | 5-1/2FH | 7 1/4 | 3 1/4 |

| 5 | 25.60 | IEU | E | BLIDS®50 | 6 1/2 | 3 3/4 |

| 5 | 25.60 | IEU | X / G | BLIDS®50 | 6 5/8 | 3 1/2 |

| 5 | 25.60 | IEU | S / Z / V | BLIDS®50 | 6 5/8 | 3 |

| 5 | 25.60 | IEU | G | BLMT®50 | 6 5/8 | 3 1/2 |

| 5 | 25.60 | IEU | S / Z / V | BLMT®50 | 6 5/8 | 3 |

| 5 | 25.60 | IEU | E | BLST®46 | 6 | 3 1/2 |

| 5 | 25.60 | IEU | X | BLST®46 | 6 | 3 1/4 |

| 5 | 25.60 | IEU | G | BLST®46 | 6 1/4 | 3 |

| 5 | 25.60 | IEU | S | BLST®46 | 6 1/4 | 2 3/4 |

| 5 | 25.60 | IEU | E / X / G | BLST®52 | 6 5/8 | 3 3/4 |

| 5 | 25.60 | IEU | S / Z / V | BLST®52 | 6 5/8 | 3 1/4 |

| 5 | 25.60 | IEU | G | BLIST®50 | 6 5/8 | 3 3/4 |

| 5 | 25.60 | IEU | S / Z / V | BLIST®50 | 6 5/8 | 3 1/4 |

| 5 1/2 | 21.90 | IEU | E | 5-1/2FH | 7 | 4 |

| 5 1/2 | 21.90 | IEU | X | 5-1/2FH | 7 | 3 3/4 |

| 5 1/2 | 21.90 | IEU | G | 5-1/2FH | 7 1/4 | 3 1/2 |

| 5 1/2 | 21.90 | IEU | S | 5-1/2FH | 7 1/2 | 3 |

| 5 1/2 | 21.90 | IEU | E / X / G / S / Z / V / U | BLIDS®5-1/2FH | 7 | 4 |

| 5 1/2 | 21.90 | IEU | G / S / Z / V / U | BLMT®5-1/2FH | 7 | 4 |

| 5 1/2 | 21.90 | IEU | E / X / G | BLST®52 | 6 1/2 | 4 |

| 5 1/2 | 21.90 | IEU | S | BLST®52 | 6 5/8 | 3 3/4 |

| 5 1/2 | 21.90 | IEU | E / X / G | BLST®54 | 6 5/8 | 4 1/4 |

| 5 1/2 | 21.90 | IEU | S | BLST®54 | 6 3/4 | 4 |

| 5 1/2 | 21.90 | IEU | Z / V | BLST®54 | 6 7/8 | 3 7/8 |

| 5 1/2 | 21.90 | IEU | G / S / Z / V / U | BLST®57 | 7 | 4 1/4 |

| 5 1/2 | 21.90 | IEU | G | BLIST®54 | 6 5/8 | 4 1/4 |

| 5 1/2 | 21.90 | IEU | S / Z / V | BLIST®54 | 6 3/4 | 4 |

| 5 1/2 | 21.90 | IEU | G / S / Z / V / U | BLIST®57 | 7 | 4 1/4 |

| 5 1/2 | 24.70 | IEU | E | 5-1/2FH | 7 | 4 |

| 5 1/2 | 24.70 | IEU | X / G | 5-1/2FH | 7 1/4 | 3 1/2 |

| 5 1/2 | 24.70 | IEU | S | 5-1/2FH | 7 1/2 | 3 |

| 5 1/2 | 24.70 | IEU | E / X / G | BLIDS®5-1/2FH | 7 | 4 |

| 5 1/2 | 24.70 | IEU | S / Z / V / U | BLIDS®5-1/2FH | 7 1/4 | 3 3/4 |

| 5 1/2 | 24.70 | IEU | G / S | BLMT®5-1/2FH | 7 | 4 |

| 5 1/2 | 24.70 | IEU | Z / V / U | BLMT®5-1/2FH | 7 1/4 | 3 3/4 |

| 5 1/2 | 24.70 | IEU | G | BLST®54 | 6 3/4 | 4 |

| 5 1/2 | 24.70 | IEU | S / Z / V | BLST®54 | 6 7/8 | 3 3/4 |

| 5 1/2 | 24.70 | IEU | G / S / Z / V / U | BLST®57 | 7 1/8 | 4 |

| 5 1/2 | 24.70 | IEU | G | BLIST®54 | 6 3/4 | 4 |

| 5 1/2 | 24.70 | IEU | S / Z / V | BLIST®54 | 6 7/8 | 3 3/4 |

| 5 1/2 | 24.70 | IEU | G / S / Z / V / U | BLIST®57 | 7 1/8 | 4 |

| 5 7/8 | 23.40 | IEU | S / Z / V / U | BLIDS®5-1/2FH | 7 1/4 | 4 |

| 5 7/8 | 23.40 | IEU | S / Z / V / U | BLMT®5-1/2FH | 7 1/4 | 4 |

| Notes: | ||||||

| Abbreviated steel grade: E – E75; X – X95; G – G105; S – S135; Z – BLDT-SH®Z140; V – BLDT-SH®V150; U – BLDT-SH®U165. The tool joint OD and ID listed above are the dimensions commonly used in drilling. It can be customized according to the actual well conditions and user requirements. |

||||||

Table B.2 Sour Service Drill Pipes Data |

||||||

| Pipe Body OD | Nominal Weight | Upset Type | Grade | RSC Type | Tool Joint | |

| (in) | (lb/ft) | OD (in) | ID (in) | |||

| 2 3/8 | 6.65 | EU | SS75 / SS95 / SS105 / BL110SS | NC26 | 3 3/8 | 1 3/4 |

| 2 3/8 | 6.65 | EU | SS75 / SS95 / SS105 / BL110SS / BL120S | BLIDS®26 | 3 3/8 | 1 3/4 |

| 2 3/8 | 6.65 | EU | SS105 / BL110SS / BL120S | BLST®26 | 3 3/8 | 1 3/4 |

| 2 3/8 | 6.65 | IU | SS105 / BL110SS / BL120S | BLIDS®23 | 3 | 1 3/8 |

| 2 3/8 | 6.65 | IU | SS105 / BL110SS / BL120S | BLMT®2-3/8PAC | 2 7/8 | 1 3/8 |

| 2 7/8 | 10.40 | EU | SS75 | NC31 | 4 1/8 | 2 1/8 |

| 2 7/8 | 10.40 | EU | SS95 / SS105 / BL110SS | NC31 | 4 1/8 | 2 |

| 2 7/8 | 10.40 | EU | SS105 / BL110SS / BL120S | BLIDS®31 | 4 1/8 | 2 |

| 2 7/8 | 10.40 | EU | SS105 / BL110SS / BL120S | BLST®31 | 4 1/8 | 2 |

| 2 7/8 | 10.40 | IU | SS75 / SS95 / SS105 / BL110SS | BLIDS®26 | 3 3/8 | 1 3/4 |

| 2 7/8 | 10.40 | IU | SS75 / SS95 / SS105 / BL110SS | BLMT®2-7/8PAC | 3 1/8 | 1 1/2 |

| 2 7/8 | 10.40 | IU | SS75 / SS95 / SS105 / BL110SS | BLST®26 | 3 3/8 | 1 3/4 |

| 3 1/2 | 13.30 | EU | SS75 | NC38 | 4 3/4 | 2 11/16 |

| 3 1/2 | 13.30 | EU | SS95 | NC38 | 5 | 2 9/16 |

| 3 1/2 | 13.30 | EU | SS105 / BL110SS | NC38 | 5 | 2 7/16 |

| 3 1/2 | 13.30 | EU | SS105 / BL110SS / BL120S | BLIDS®38 | 5 | 2 9/16 |

| 3 1/2 | 13.30 | EU | SS105 / BL110SS / BL120S | BLMT®38 | 4 7/8 | 2 9/16 |

| 3 1/2 | 13.30 | EU | SS105 / BL110SS / BL120S | BLST®36 | 4 3/4 | 2 1/4 |

| 3 1/2 | 13.30 | EU | SS105 / BL110SS / BL120S | BLST®39 | 4 7/8 | 2 11/16 |

| 3 1/2 | 13.30 | EU | SS105 / BL110SS / BL120S | BLIST®38 | 4 3/4 | 2 9/16 |

| 3 1/2 | 13.30 | EU | SS105 / BL110SS / BL120S | BLIST®39 | 4 7/8 | 2 11/16 |

| 3 1/2 | 13.30 | IU | SS75 / SS95 / SS105 / BL110SS | BLIDS®31 | 4 1/8 | 2 |

| 3 1/2 | 13.30 | IU | SS75 / SS95 / SS105 / BL110SS | BLST®31 | 4 1/8 | 2 |

| 3 1/2 | 15.50 | EU | SS75 | NC38 | 5 | 2 9/16 |

| 3 1/2 | 15.50 | EU | SS95 | NC38 | 5 | 2 7/16 |

| 3 1/2 | 15.50 | EU | SS105 / BL110SS | NC38 | 5 | 2 1/8 |

| 3 1/2 | 15.50 | EU | SS105 / BL110SS / BL120S | BLIDS®38 | 5 | 2 7/16 |

| 3 1/2 | 15.50 | EU | SS105 / BL110SS / BL120S | BLMT®38 | 4 7/8 | 2 7/16 |

| 3 1/2 | 15.50 | EU | SS105 / BL110SS / BL120S | BLST®36 | 4 3/4 | 2 1/8 |

| 3 1/2 | 15.50 | EU | SS105 / BL110SS / BL120S | BLST®39 | 5 | 2 9/16 |

| 3 1/2 | 15.50 | EU | SS105 / BL110SS / BL120S | BLIST®38 | 4 3/4 | 2 7/16 |

| 3 1/2 | 15.50 | EU | SS105 / BL110SS/ BL120S | BLIST®39 | 4 7/8 | 2 9/16 |

| 4 | 14.00 | IU | SS75 | NC40 | 5 1/4 | 2 13/16 |

| 4 | 14.00 | IU | SS95 | NC40 | 5 1/4 | 2 11/16 |

| 4 | 14.00 | IU | SS105 / BL110SS | NC40 | 5 1/2 | 2 7/16 |

| 4 | 14.00 | IU | SS105 / BL110SS / BL120S / BL125S | BLIDS®38 | 5 | 2 9/16 |

| 4 | 14.00 | IU | SS105 / BL110SS / BL120S / BL125S | BLIDS®40 | 5 1/4 | 2 11/16 |

| 4 | 14.00 | IU | SS105 / BL110SS / BL120S / BL125S | BLMT®38 | 5 | 2 9/16 |

| 4 | 14.00 | IU | SS105 / BL110SS / BL120S / BL125S | BLMT®40 | 5 1/4 | 2 11/16 |

| 4 | 14.00 | IU | SS105 / BL110SS / BL120S / BL125S | BLST®36 | 4 3/4 | 2 1/8 |

| 4 | 14.00 | IU | SS105 / BL110SS / BL120S / BL125S | BLST®39 | 4 7/8 | 2 9/16 |

| 4 | 14.00 | IU | SS105 / BL110SS / BL120S / BL125S | BLIST®38 | 4 3/4 | 2 7/16 |

| 4 | 14.00 | IU | SS105 / BL110SS / BL120S / BL125S | BLIST®39 | 4 7/8 | 2 9/16 |

| 4 | 15.70 | IU | SS105 / BL110SS / BL120S / BL125S | BLIDS®40 | 5 1/4 | 2 9/16 |

| 4 | 15.70 | IU | SS105 / BL110SS / BL120S / BL125S | BLMT®40 | 5 1/4 | 2 9/16 |

| 4 | 15.70 | IU | SS105 / BL110SS / BL120S / BL125S | BLST®39 | 4 7/8 | 2 9/16 |

| 4 | 15.70 | IU | SS105 / BL110SS / BL120S / BL125S | BLST®40 | 5 1/4 | 2 11/16 |

| 4 | 15.70 | IU | SS105 / BL110SS / BL120S / BL125S | BLIST®39 | 4 7/8 | 2 9/16 |

| 4 1/2 | 16.60 | IEU | SS75 | NC46 | 6 1/4 | 3 1/4 |

| 4 1/2 | 16.60 | IEU | SS95 / SS105 / BL110SS | NC46 | 6 1/4 | 3 |

| 4 1/2 | 16.60 | IEU | BL120S / BL125S | NC46 | 6 1/4 | 2 3/4 |

| 4 1/2 | 16.60 | IEU | SS105 / BL110SS / BL120S / BL125S | BLIDS®46 | 6 | 3 1/4 |

| 4 1/2 | 16.60 | IEU | SS105 / BL110SS / BL120S / BL125S | BLMT®46 | 6 | 3 1/4 |

| 4 1/2 | 16.60 | IEU | SS105 / BL110SS / BL120S / BL125S | BLST®46 | 6 | 3 1/4 |

| 4 1/2 | 16.60 | IEU | SS105 / BL110SS / BL120S / BL125S | BLIST®46 | 6 | 3 1/4 |

| 4 1/2 | 16.60 | IEU | SS105 / BL110SS / BL120S / BL125S | BLIDS®40 | 5 1/4 | 2 9/16 |

| 4 1/2 | 16.60 | IEU | SS105 / BL110SS / BL120S / BL125S | BLST®40 | 5 1/4 | 2 11/16 |

| 4 1/2 | 20.00 | IEU | SS75 | NC46 | 6 1/4 | 3 |

| 4 1/2 | 20.00 | IEU | SS95 | NC46 | 6 1/4 | 2 3/4 |

| 4 1/2 | 20.00 | IEU | SS105 / BL110SS | NC46 | 6 1/4 | 2 1/2 |

| 4 1/2 | 20.00 | IEU | BL120S / BL125S | NC46 | 6 1/4 | 2 1/4 |

| 4 1/2 | 20.00 | IEU | SS105 / BL110SS / BL120S / BL125S | BLIDS®46 | 6 | 3 |

| 4 1/2 | 20.00 | IEU | SS105 / BL110SS / BL120S / BL125S | BLMT®46 | 6 | 3 |

| 4 1/2 | 20.00 | IEU | SS105 / BL110SS / BL120S / BL125S | BLST®46 | 6 | 3 |

| 4 1/2 | 20.00 | IEU | SS105 / BL110SS / BL120S / BL125S | BLIST®46 | 6 | 3 |

| 5 | 19.50 | IEU | SS75 | NC50 | 6 5/8 | 3 3/4 |

| 5 | 19.50 | IEU | SS95 | NC50 | 6 5/8 | 3 1/2 |

| 5 | 19.50 | IEU | SS105 / BL110SS | NC50 | 6 5/8 | 3 1/4 |

| 5 | 19.50 | IEU | SS105 / BL110SS / BL120S / BL125S | BLIDS®50 | 6 5/8 | 3 1/2 |

| 5 | 19.50 | IEU | SS105 / BL110SS / BL120S / BL125S | BLMT®50 | 6 5/8 | 3 1/2 |

| 5 | 19.50 | IEU | SS105 / BL110SS / BL120S / BL125S | BLST®46 | 6 | 3 1/4 |

| 5 | 19.50 | IEU | SS75 / SS95 / SS105 / BL110SS | BLST®52 | 6 1/2 | 4 |

| 5 | 19.50 | IEU | BL120S / BL125S | BLST®52 | 6 1/2 | 3 3/4 |

| 5 | 19.50 | IEU | SS105 / BL110SS / BL120S / BL125S | BLIST®46 | 6 | 3 1/2 |

| 5 | 19.50 | IEU | SS105 / BL110SS / BL120S / BL125S | BLIST®50 | 6 1/2 | 3 3/4 |

| 5 | 25.60 | IEU | SS75 | NC50 | 6 5/8 | 3 1/2 |

| 5 | 25.60 | IEU | SS95 | NC50 | 6 5/8 | 3 |

| 5 | 25.60 | IEU | SS105 / BL110SS | NC50 | 6 5/8 | 2 3/4 |

| 5 | 25.60 | IEU | SS105 / BL110SS / BL120S / BL125S | BLIDS®50 | 6 5/8 | 3 |

| 5 | 25.60 | IEU | SS105 / BL110SS / BL120S / BL125S | BLMT®50 | 6 5/8 | 3 |

| 5 | 25.60 | IEU | SS105 / BL110SS / BL120S / BL125S | BLST®46 | 6 1/4 | 2 3/4 |

| 5 | 25.60 | IEU | SS105 / BL110SS / BL120S / BL125S | BLST®52 | 6 5/8 | 3 3/8 |

| 5 | 25.60 | IEU | SS105 / BL110SS / BL120S / BL125S | BLIST®50 | 6 5/8 | 3 1/2 |

| 5 1/2 | 21.90 | IEU | SS75 | 5-1/2FH | 7 | 4 |

| 5 1/2 | 21.90 | IEU | SS95 | 5-1/2FH | 7 | 3 3/4 |

| 5 1/2 | 21.90 | IEU | SS105 / BL110SS | 5-1/2FH | 7 1/4 | 3 1/2 |

| 5 1/2 | 21.90 | IEU | SS105 / BL110SS / BL120S / BL125S | BLIDS®5-1/2FH | 7 | 4 |

| 5 1/2 | 21.90 | IEU | SS105 / BL110SS / BL120S / BL125S | BLMT®5-1/2FH | 7 | 4 |

| 5 1/2 | 21.90 | IEU | SS105 / BL110SS / BL120S / BL125S | BLST®52 | 6 1/2 | 3 3/4 |

| 5 1/2 | 21.90 | IEU | SS105 / BL110SS / BL120S / BL125S | BLST®54 | 6 3/4 | 4 |

| 5 1/2 | 21.90 | IEU | SS105 / BL110SS / BL120S / BL125S | BLST®57 | 7 | 4 1/8 |

| 5 1/2 | 21.90 | IEU | SS105 / BL110SS/ BL120S / BL125S | BLIST®54 | 6 5/8 | 4 |

| 5 1/2 | 21.90 | IEU | SS105 / BL110SS / BL120S / BL125S | BLIST®57 | 7 | 4 1/8 |

| 5 1/2 | 24.70 | IEU | SS75 | 5-1/2FH | 7 | 4 |

| 5 1/2 | 24.70 | IEU | SS95 / SS105 / BL110SS | 5-1/2FH | 7 1/4 | 3 1/2 |

| 5 1/2 | 24.70 | IEU | SS105 / BL110SS / BL120S / BL125S | BLIDS®5-1/2FH | 7 | 4 |

| 5 1/2 | 24.70 | IEU | SS105 / BL110SS / BL120S / BL125S | BLMT®5-1/2FH | 7 | 4 |

| 5 1/2 | 24.70 | IEU | SS105 / BL110SS / BL120S / BL125S | BLST®54 | 6 7/8 | 3 7/8 |

| 5 1/2 | 24.70 | IEU | SS105 / BL110SS / BL120S / BL125S | BLST®57 | 7 | 4 |

| 5 1/2 | 24.70 | IEU | SS105 / BL110SS / BL120S / BL125S | BLIST®54 | 6 3/4 | 3 7/8 |

| 5 1/2 | 24.70 | IEU | SS105 / BL110SS / BL120S / BL125S | BLIST®57 | 7 | 4 |

| 5 7/8 | 23.40 | IEU | SS75 | 5-1/2FH | 7 | 4 |

| 5 7/8 | 23.40 | IEU | SS95 / SS105 / BL110SS | 5-1/2FH | 7 1/4 | 3 1/2 |

| 5 7/8 | 23.40 | IEU | BL120S / BL125S | BLIDS®5-1/2FH | 7 | 4 |

| 5 7/8 | 23.40 | IEU | BL120S / BL125S | BLMT®5-1/2FH | 7 | 4 |

| 5 7/8 | 23.40 | IEU | BL120S / BL125S | BLST®57 | 7 | 4 1/4 |

| Note: Abbreviated steel grade | ||||||

| SS75 – BLDT-SS®75; SS95 – BLDT-SS®95; SS105 – BLDT-SS® 105; BL110SS – BLDT-SS® 110; BL120S – BLDT-S® 120; BL125S – BLDT-S® 125. |

||||||

Table B.4 Drill Collars Data |

|||||||

| Size | OD | Bore | RSC Type | Length | RSC Bevel Dia. |

Reference Bending Strength Ratio |

Drift |

| D | d | L | Df | BSR | |||

| in | in | in | FT | in | in | ||

| 3 1/8 | 3 1/8 | 1 1/4 | NC23 | 30 | 3.000 | 2.57 | 1.375 |

| 3 1/2 | 3 1/2 | 1 1/2 | NC26 | 30 | 3.266 | 2.42 | 1.625 |

| 4 1/8 | 4 1/8 | 2 | NC31 | 30 or 31 | 3.953 | 2.43 | 2.125 |

| 4 3/4 | 4 3/4 | 2 | NC35 | 30 or 31 | 4.516 | 2.58 | 2.125 |

| 5 | 5 | 2 1/4 | NC38 | 30 or 31 | 4.766 | 2.38 | 2.375 |

| 6 | 6 | 2 1/4 | NC44 | 30 or 31 | 5.688 | 2.49 | 2.375 |

| 6 | 6 | 2 13/16 | NC44 | 30 or 31 | 5.688 | 2.84 | 2.938 |

| 6 1/4 | 6 1/4 | 2 1/4 | NC44 | 30 or 31 | 5.875 | 2.91 | 2.375 |

| 6 1/4 | 6 1/4 | 2 13/16 | NC46 | 30 or 31 | 5.906 | 2.63 | 2.938 |

| 6 1/2 | 6 1/2 | 2 1/4 | NC46 | 30 or 31 | 6.094 | 2.76 | 2.375 |

| 6 1/2 | 6 1/2 | 2 13/16 | NC46 | 30 or 31 | 6.094 | 3.05 | 2.938 |

| 6 3/4 | 6 3/4 | 2 1/4 | NC46 | 30 or 31 | 6.281 | 3.18 | 2.375 |

| 7 | 7 | 2 1/4 | NC50 | 30 or 31 | 6.484 | 2.54 | 2.375 |

| 7 | 7 | 2 13/16 | NC50 | 30 or 31 | 6.484 | 2.73 | 2.938 |

| 7 1/4 | 7 1/4 | 2 13/16 | NC50 | 30 or 31 | 6.672 | 3.12 | 2.938 |

| 7 3/4 | 7 3/4 | 2 13/16 | NC56 | 30 or 31 | 7.297 | 2.70 | 2.938 |

| 8 | 8 | 2 13/16 | NC56 | 30 or 31 | 7.484 | 3.02 | 2.938 |

| 8 1/4 | 8 1/4 | 2 13/16 | 6-5/8REG | 30 or 31 | 7.703 | 2.93 | 2.938 |

| 9 | 9 | 2 13/16 | NC61 | 30 or 31 | 8.375 | 3.17 | 2.938 |

| 9 1/2 | 9 1/2 | 3 | 7-5/8REG | 30 or 31 | 8.813 | 2.81 | 3.125 |

| 9 3/4 | 9 3/4 | 3 | NC70 | 30 or 31 | 9.156 | 2.57 | 3.125 |

| 10 | 10 | 3 | NC70 | 30 or 31 | 9.344 | 2.81 | 3.125 |

| 11 | 11 | 3 | 8-5/8REG | 30 or 31 | 10.500 | 2.84 | 3.125 |

Table B.5 BLIDS® Connection Mechanical Characteristics |

|||||

| RSC Type | Tool Joint OD (in) |

Tool Joint ID (in) |

Torsional Strength (ft-lb) |

Tensile Strength (lb) |

Recommended Makeup Torque (ft-lb) |

| BLIDS®23 | 3.000 | 1.375 | 6500 | 284200 | 3900 |

| BLIDS®26 | 3.375 | 1.750 | 8900 | 313700 | 5300 |

| BLIDS®31 | 4.375 | 1.625 | 24000 | 623800 | 14400 |

| 4.125 | 2.125 | 15300 | 447100 | 9200 | |

| 4.125 | 2.000 | 17700 | 495700 | 10600 | |

| BLIDS®38 | 5.000 | 2.563 | 26600 | 649200 | 16000 |

| 5.000 | 2.438 | 30000 | 708100 | 18000 | |

| 5.000 | 2.125 | 37500 | 842400 | 22500 | |

| 4.750 | 2.688 | 22800 | 587300 | 13700 | |

| 4.750 | 2.563 | 25400 | 649200 | 15300 | |

| BLIDS®40 | 5.500 | 2.000 | 51800 | 1080100 | 31100 |

| 5.250 | 2.813 | 29500 | 711600 | 17700 | |

| 5.250 | 2.688 | 33400 | 776400 | 20100 | |

| 5.250 | 2.563 | 37200 | 838300 | 22300 | |

| 5.250 | 2.438 | 40300 | 897200 | 24200 | |

| BLIDS®46 | 6.000 | 3.250 | 44000 | 901200 | 26400 |

| 6.000 | 3.000 | 54100 | 1048400 | 32500 | |

| 6.000 | 2.750 | 63200 | 1183900 | 37900 | |

| BLIDS®50 | 6.625 | 3.750 | 48800 | 939100 | 29300 |

| 6.625 | 3.500 | 61600 | 1109900 | 37000 | |

| 6.625 | 3.250 | 73400 | 1269000 | 44000 | |

| 6.625 | 3.000 | 84100 | 1416200 | 50500 | |

| 6.625 | 2.750 | 93900 | 1551700 | 56300 | |

| 6.500 | 3.750 | 48600 | 939100 | 29200 | |

| BLIDS®5-1/2FH | 7.500 | 3.250 | 117000 | 1778300 | 70200 |

| 7.500 | 3.000 | 128700 | 1925500 | 77200 | |

| 7.250 | 3.750 | 89800 | 1448400 | 53900 | |

| 7.250 | 3.625 | 96900 | 1535300 | 58100 | |

| 7.250 | 3.500 | 103600 | 1619200 | 62200 | |

| 7.000 | 4.000 | 74400 | 1265800 | 44700 | |

| 7.000 | 3.875 | 82000 | 1358600 | 49200 | |

| BLIDS®6-5/8FH | 8.250 | 4.750 | 119700 | 1678100 | 71800 |

| 8.250 | 4.625 | 130200 | 1788600 | 78100 | |

| 8.000 | 5.000 | 97200 | 1448400 | 58300 | |

| 8.000 | 4.875 | 108300 | 1564800 | 65000 | |

| Note: All data is calculated based on SMYS 120ksi, and Makeup Torques are based on a friction factor of 1.0. | |||||

| Table B. 6 BLMT® Connection Mechanical Characteristics | |||||

| RSC Type | Tool Joint OD (in) |

Tool Joint ID (in) |

Torsional Strength (ft-lb) |

Tensile Strength (lb) |

Recommended Makeup Torque (ft-lb) |

| BLMT®2-3/8PAC | 2.875 | 1.375 | 7000 | 238500 | 4200 |

| BLMT®2-7/8PAC | 3.125 | 1.500 | 8500 | 273000 | 5100 |

| BLMT®38 | 5.000 | 2.563 | 29600 | 649200 | 17700 |

| 5.000 | 2.438 | 33000 | 708100 | 19800 | |

| 5.000 | 2.250 | 37700 | 790900 | 22600 | |

| 4.875 | 2.438 | 32800 | 708100 | 19700 | |

| 4.750 | 2.688 | 25700 | 587300 | 15400 | |

| 4.750 | 2.563 | 28400 | 649200 | 17000 | |

| BLMT®40 | 5.500 | 2.438 | 43800 | 897200 | 26300 |

| 5.250 | 2.688 | 36100 | 776400 | 21700 | |

| 5.250 | 2.563 | 39900 | 838300 | 23900 | |

| 5.250 | 2.438 | 43100 | 897200 | 25800 | |

| BLMT®46 | 6.000 | 3.250 | 47200 | 901200 | 28300 |

| 6.000 | 3.000 | 57300 | 1048400 | 34400 | |

| BLMT®50 | 6.625 | 3.500 | 66200 | 1109900 | 39700 |

| 6.625 | 3.250 | 78000 | 1269000 | 46800 | |

| 6.625 | 3.000 | 88800 | 1416200 | 53300 | |

| 6.500 | 3.500 | 65900 | 1109900 | 39600 | |

| BLMT®5-1/2FH | 7.000 | 4.000 | 77200 | 1265800 | 46300 |

| BLMT®5-1/2FH | 7.000 | 3.875 | 84800 | 1358600 | 50900 |

| Note: All data is calculated based on SMYS 120ksi, and Makeup Torques are based on a friction factor of 1.0. | |||||

| Table B. 7 BLST® Connection Mechanical Characteristics | |||||

| RSC Type | Tool Joint OD (in) |

Tool Joint ID (in) |

Torsional Strength (ft-lb) |

Tensile Strength (lb) |

Recommended Makeup Torque (ft-lb) |

| BLST®26 | 3.375 | 1.750 | 11100 | 296500 | 6600 |

| BLST®31 | 4.125 | 2.125 | 19000 | 433900 | 11400 |

| 4.125 | 2.000 | 21500 | 482500 | 12900 | |

| 4.000 | 2.250 | 16300 | 382300 | 9800 | |

| BLST®36 | 4.750 | 2.563 | 24400 | 502700 | 14700 |

| 4.750 | 2.438 | 27800 | 561600 | 16700 | |

| 4.750 | 2.250 | 32400 | 644500 | 19500 | |

| 4.750 | 2.125 | 35300 | 696000 | 21200 | |

| BLST®39 | 5.000 | 2.563 | 38900 | 723300 | 23300 |

| 5.000 | 2.438 | 41900 | 782200 | 25100 | |

| 4.875 | 2.813 | 31100 | 596700 | 18600 | |

| 4.875 | 2.688 | 34600 | 661500 | 20800 | |

| 4.875 | 2.563 | 36300 | 723300 | 21800 | |

| BLST®40 | 5.375 | 2.563 | 49800 | 869300 | 29900 |

| 5.250 | 2.688 | 45800 | 807500 | 27500 | |

| 5.250 | 2.563 | 49000 | 869300 | 29400 | |

| BLST®46 | 6.250 | 3.000 | 70100 | 1090700 | 42000 |

| 6.250 | 2.750 | 79600 | 1226200 | 47700 | |

| 6.000 | 3.500 | 47800 | 784400 | 28700 | |

| 6.000 | 3.250 | 59200 | 943400 | 35500 | |

| 6.000 | 3.000 | 69600 | 1090700 | 41800 | |

| BLST®52 | 6.625 | 4.000 | 62300 | 917500 | 37400 |

| 6.625 | 3.750 | 76800 | 1100100 | 46100 | |

| 6.625 | 3.500 | 90300 | 1270900 | 54200 | |

| 6.500 | 4.125 | 54500 | 821700 | 32700 | |

| 6.500 | 4.000 | 62100 | 917500 | 37300 | |

| BLST®54 | 6.875 | 3.750 | 98800 | 1333800 | 59300 |

| 6.750 | 4.125 | 75700 | 1055400 | 45400 | |

| 6.750 | 4.000 | 83600 | 1151200 | 50100 | |

| 6.625 | 4.250 | 67300 | 956800 | 40400 | |

| BLST®57 | 7.125 | 4.000 | 109800 | 1437800 | 65900 |

| 7.000 | 4.250 | 92900 | 1243400 | 55700 | |

| 7.000 | 4.000 | 103000 | 1437800 | 61800 | |

| Note: All data is calculated based on SMYS 120ksi, and Makeup Torques are based on a friction factor of 1.0. | |||||

| Table B. 8 BLIST® Connection Mechanical Characteristics | |||||

| RSC Type | Tool Joint OD (in) |

Tool Joint ID (in) |

Torsional Strength (ft-lb) |

Tensile Strength (lb) |

Recommended Makeup Torque (ft-lb) |

| BLIST®38 | 4.875 | 2.438 | 34900 | 658500 | 20900 |

| 4.750 | 2.688 | 27700 | 537800 | 16600 | |

| 4.750 | 2.563 | 31300 | 599600 | 18800 | |

| 4.750 | 2.438 | 34800 | 658500 | 20900 | |

| BLIST®39 | 5.000 | 2.563 | 40800 | 729700 | 24500 |

| 4.875 | 2.688 | 35900 | 667800 | 21600 | |

| 4.875 | 2.563 | 37600 | 729700 | 22600 | |

| BLIST®46 | 6.250 | 3.250 | 70200 | 1069300 | 42100 |

| 6.000 | 3.500 | 58100 | 910300 | 34900 | |

| 6.000 | 3.250 | 65700 | 1069300 | 39400 | |

| BLIST®50 | 6.625 | 3.500 | 90900 | 1256300 | 54600 |

| 6.625 | 3.375 | 97200 | 1337300 | 58300 | |

| 6.500 | 3.750 | 77300 | 1085500 | 46400 | |

| 6.500 | 3.625 | 84100 | 1172400 | 50500 | |

| BLIST®54 | 6.750 | 4.000 | 86600 | 1155100 | 52000 |

| 6.750 | 3.875 | 94300 | 1247900 | 56600 | |

| 6.625 | 4.250 | 70200 | 960700 | 42100 | |

| 6.625 | 4.000 | 84300 | 1155100 | 50600 | |

| BLIST®57 | 7.000 | 4.250 | 94600 | 1208700 | 56800 |

| 7.000 | 4.000 | 107700 | 1403100 | 64600 | |

| Note: All data is calculated based on SMYS 120ksi, and Makeup Torques are based on a friction factor of 1.0. | |||||

Balingsteel Can Supply Not Only New Drill Pipe but Also Used Drill Pipe, Please Let Us Know Your Specifications and We Will Provide You with an Official Quotation Program.

We Measure the Dimensions of the Joints and Tubes of the Drill Pipe Using a Series of Specialized Testing Equipment, Such as Tape Measure, Vernier Calipers, Thickness Gauges, And so On. If You Find It Troublesome, I Can Test It for You or Commission a Third-Party Inspection for You.

Drill Pipe Can Not Be Cut Arbitrarily, If You Still Need to Cut, Please Get in Touch with Us in Time, We Will Remote Technical Guidance for Your Operation!

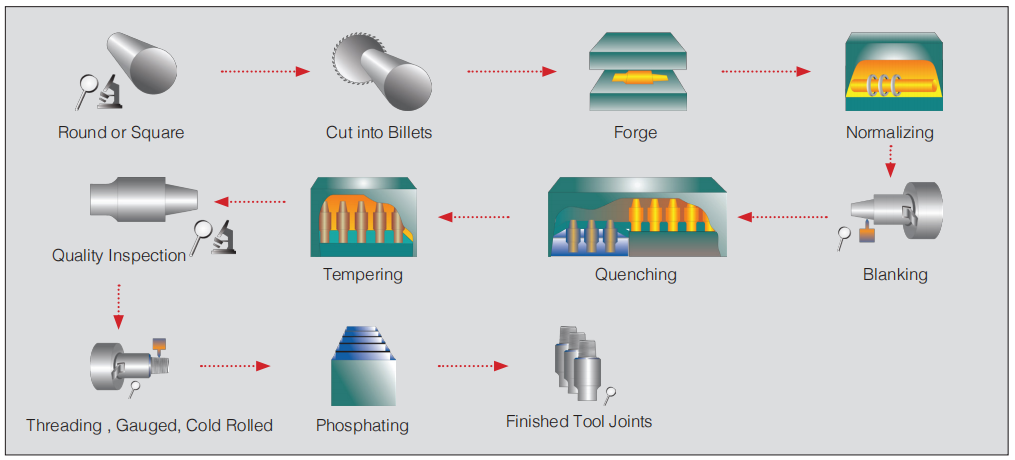

How Is Drill Pipe Manufactured?

-

Tool Joint Manufacturing Flow Chart:

Round or Square——Cut into Billets——Forge——Normalizing——Blanking——Quenching——Tempering——Quality Inspection——Threading , Gauged, Cold Rolled——Phosphating——Phosphating

-

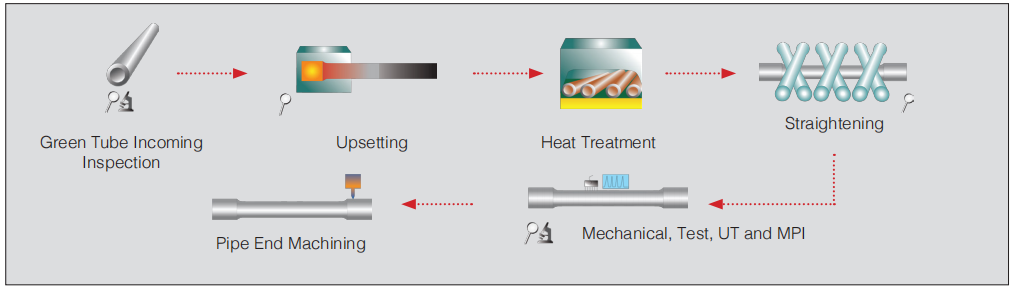

Drill Pipe Body Manufacturing Flow Chart:

Green Tube Incoming Inspection——Upsetting——Heat Treatment——Straightening——Mechanical, Test, Ut and MPI——Pipe End Machining

-

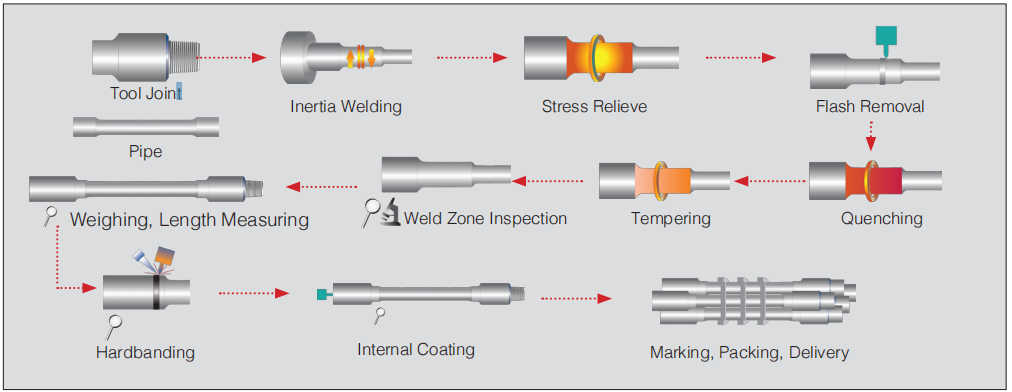

Drill Pipe Welding Flow Chart:

Tool Joint——Inertia Welding——Stress Relieve——Flash Removal——Quenching——Tempering——Weld Zone Inspection——Weighing, Length Measuring——Hardbanding——Internal Coating——Marking, Packing, Delivery

If You Would like to Learn More About Drill Pipe and Balingsteel, Contact Us Today!