Introduction

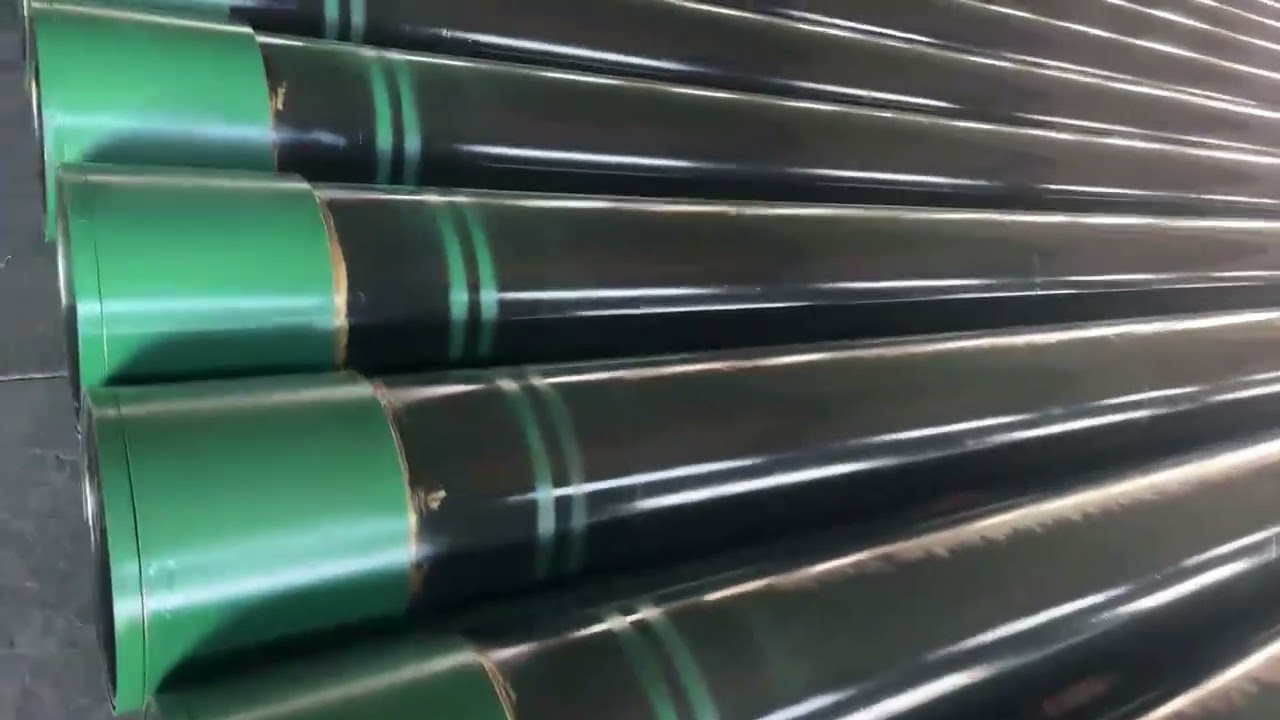

Balingsteel Is a Supplier of Tubing and Casing and We Have over 25 Years of Experience. We Have Provided the World with High Quality Oil Casing and Tubing Products. In This Article, We Will Take You Through the Definition, Uses, And Types of Petroleum Casing and Tubing to Differentiate Them from the Perspective of a Senior Industry Professional.

Key Differences Between Casing and Tubing

Differences in Size

The Size of the Oil Casing Is Generally Larger Than the Oil Tubing, So That the Oil Tubing Can Be Placed Inside the Oil Casing.

Differences in Ending designing

You Can Choose from a Wide Range of Buckle Types for Petroleum Casing, But the Buckle Types for Petroleum Tubing Are Basically EUE and NUE.

Differences in Length

The Length of Petroleum Casing Is Generally R2 and R3 Lengths, And the Length of Petroleum Tubing Is Basically R1 or R2 or Even Shorter.

Differences in Function

The Main Function of Oil Casing Is for Supporting and Isolating the Oil Wells from the Soil, And Oil Tubing Is Mainly for Pumping Crude Oil from the Oil Wells to the Surface.

Differences in Performance

Petroleum Casing Is Mainly Supportive and Therefore Requires High Resistance to External Pressure, While Petroleum Tubing Is Mainly Conveying and Therefore Needs to Withstand Greater Internal Pipeline Pressure.

Understanding Casing

What is Casing?

Petroleum Casing Is the Main Support Component of Oil Extraction Wells, With a Large Caliber and a Buckle-Type Connection Attached to Both Ends of the Casing. After the Drill Pipe Is Used, The Casing Needs to Be Laid Immediately to Stabilize the Oil Extraction Wellhead.

Types of Casing

Range:

| OD: | 4-1/2 to 20 Inch | 114.3~508MM |

| PPF: | 9.5~133 | |

| Length: | R2,R3 | 7.62~14.63M |

| Coating: | ACC API 5CT | |

Ending designing:

| Category | Thread Type | Application | Features | Sealing Performance | Tensile Strength |

| API Standard Threads | STC (Short Thread Coupling) |

Casing | Simple structure, easy to install | General | General |

| LTC (Long Thread Coupling) |

Casing | Longer thread, higher connection strength | General | High | |

| BTC (Buttress Thread Coupling) |

Casing | Larger contact area, stronger tensile capacity | General | High | |

| EUE (External Upset End) |

Casing&Tubing | Upset end for increased strength | Medium | High | |

| NUE (Non-Upset End) | Casing&Tubing | Simple structure, no upset end | Low | Low | |

| Premium Threads | VAM TOP | High-pressure, high-temperature deep wells | High gas-tightness, high tensile strength | High | High |

| VAM 21 | Extreme conditions | Advanced gas-tight design | Very High | Very High | |

| VAM FJL | Gas wells | High-performance tubing thread | High | High | |

| VAM EDGE | Large-diameter deep wells | Enhanced sealing, high-temperature resistance | High | High | |

| Hydril CS | High-pressure wells | High sealing performance, pressure-resistant | High | High | |

| Hydril PH-6 | Gas wells | Suitable for high-pressure gas wells | Very High | High | |

| Hydril FX | Extreme conditions | Pressure-resistant, corrosion-resistant | Very High | Very High | |

| TenarisBlue | High-temperature, high-pressure wells | High sealing performance | High | High | |

| TenarisHydril Wedge | Deep wells, high torque wells | Wedge-shaped thread, high torsional resistance | High | Very High | |

| JFE Fox | Deep wells, high corrosion environments | Developed by JFE, corrosion-resistant | High | High | |

| JFE Bear | Ultra-deep wells | Enhanced sealing, high-temperature resistance | High | High | |

| Hunting SL-HT | Offshore oil and gas | Suitable for high-strength operations | High | High | |

| NSCC-H | Domestic high-pressure wells | Developed by CNPC, suitable for high-pressure wells | High | High |

Materials:

| Classification Standard | Material Type | Steel Grade | Yield Strength | Tensile Strength | Main Applications |

| By API Standard | Carbon Steel Casing | J55, K55 | 379 – 552 MPa | ≥ 517 MPa | Shallow wells |

| Medium-Strength Casing | N80, L80 | 552 – 689 MPa | ≥ 655 MPa | Medium-depth wells | |

| High-Strength Casing | P110, Q125 | 758- 1034 MPa | ≥ 862 MPa | Deep wells | |

| By Corrosion Resistance | Carbon Steel Casing | J55, K55, N80 | 379 – 552 MPa | ≥ 517 MPa | Conventional wells, non-corrosive environments |

| H₂S-Resistant Casing | L80-3, C90, T95 | 552- 862 MPa | ≥ 655 MPa | Sour gas fields, acidic environments | |

| CO₂-Resistant Casing | L80-13Cr, Super 13Cr | 655- 965 MPa | ≥ 718 MPa | High CO₂-content oil and gas wells | |

| High-Corrosion-Resistant Alloy Casing | C110, C125, Inconel Alloy | 758- 1034 MPa | ≥ 862 MPa | Extreme environments, high-temperature high-pressure wells |

Understanding Tubing

What is Tubing?

Petroleum Tubing Is Piping Used to Transport Oil and Natural Gas, And It Has a Relatively Small Caliber. After the Casing Is Laid in the Oil Wellhead, A Set of Tubing Is Placed to Transport the Crude Oil from the Oil Field to the Surface Storage Tanks.

Types of Tubing

Range:

| OD: | 1.05 to 4-1/2 Inch | 26.67~114.3MM |

| PPF: | 1.14~12.75 | |

| Length: | R1,R2 | 4.88~10.36M |

| Coating: | ACC API 5CT | |

Ending designing:

| Thread Type | Application |

| API EUE and NUE | Oil and gas wells with low pressure |

| Screw Thread and UPT® | Lower-requirement wells |

| VAM®, Hydril®, TenarisHydril® Wedge, and ReedHycalog® | Deep wells, high-corrosion gas wells, and offshore oilfields. |

Materials:

| Material (Steel Grade) | Yield Strength (MPa) | Tensile Strength (MPa) |

| J55 | 379 – 552 MPa (55,000 – 80,000 psi) | ≥ 517 MPa (≥ 75,000 psi) |

| K55 | 379 – 552 MPa (55,000 – 80,000 psi) | ≥ 517 MPa (≥ 75,000 psi) |

| N80 | 552 – 758 MPa (80,000 – 110,000 psi) | ≥ 689 MPa (≥ 100,000 psi) |

| L80 | 552 – 758 MPa (80,000 – 110,000 psi) | ≥ 689 MPa (≥ 100,000 psi) |

| C90 | 621 – 758 MPa (90,000 – 110,000 psi) | ≥ 689 MPa (≥ 100,000 psi) |

| T95 | 655 – 862 MPa (95,000 – 125,000 psi) | ≥ 724 MPa (≥ 105,000 psi) |

| P110 | 758 – 965 MPa (110,000 – 140,000 psi) | ≥ 862 MPa (≥ 125,000 psi) |

| Q125 | 862 – 1034 MPa (125,000 – 150,000 psi) | ≥ 931 MPa (≥ 135,000 psi) |

| L80-13Cr | 655 – 793 MPa (95,000 – 115,000 psi) | ≥ 718 MPa (≥ 104,000 psi) |

| Super 13Cr | 758 – 965 MPa (110,000 – 140,000 psi) | ≥ 862 MPa (≥ 125,000 psi) |

| Inconel 625 | 1034 MPa (150,000 psi) | 1379 MPa (200,000 psi) |

| C110 | 758 – 965 MPa (110,000 – 140,000 psi) | ≥ 862 MPa (≥ 125,000 psi) |

| C125 | 827 – 1034 MPa (120,000 – 150,000 psi) | ≥ 965 MPa (≥ 140,000 psi) |

| Inconel Alloy | 1034 MPa (150,000 psi) | 1379 MPa (200,000 psi) |

How to Choose Casing and Tubing

- Basic Selection Criteria – When Selecting Tubing and Casing We Need to Pay Attention to the Pressure Environment and Depth of the Oil Wellhead, And Select Different Caliber, Wall Thickness and Buckle Type for Different Depth. Of Course, All Oil Casing and Tubing Are Produced Based on API5 CT

- Special Use Scenario – If the Oil Wellhead Is Shallow and the Extraction Difficulty Is Not High, Usually We Can Use the Oil Tubing Only for Supporting and Transporting the Crude Oil, Which Will Greatly Save Our Cost.

- Used Oil Casing and Tubing – Meanwhile, With Safe and Standardized Operation, Some Casing and Tubing Can Be Recycled for Secondary Use After Completing the Extraction Task.

Conclusion

Petroleum Casing and Petroleum Tubing Are the Most Commonly Used Products in the Process of Crude Oil Extraction, And They Need to Be Used in Conjunction with Each Other. We Need to Fully Understand the Characteristics and Performance of Their Products to Ensure the Smooth Construction. If You Need to Use Oil Casing and Tubing in the Oil Fields to Be Exploited, Welcome to Contact Us, We Will Provide You with the Best Oil Casing and Tubing to Carry out Your Work!

FAQ

What Is the Difference Between a Casing and a Liner?

The Casing Is the Support and Protection Pipe from the Bottom of the Well to the Surface, And the Liner Is Part of the Casing, Which Does Not Extend to the Surface.

How Does Casing Work?

First Wait for the Completion of the Drilling Stage Before the Casing Work, And Then Inject Cement Mortar Between the Casing and the Well Wall to Fix the Wellhead, And Then Continue Drilling and Then in Accordance with the Oil Casing.

What’s the Different Between Drill Pipe and Tubing?

Different Uses, Oil Tubing Is Mainly Used to Transport Oil, The Drill Pipe Is Mainly Used to Extract Oil, You Need to Use the Drill Pipe Before the Use of Oil Tubing.