Oil Well Conductor Pipe

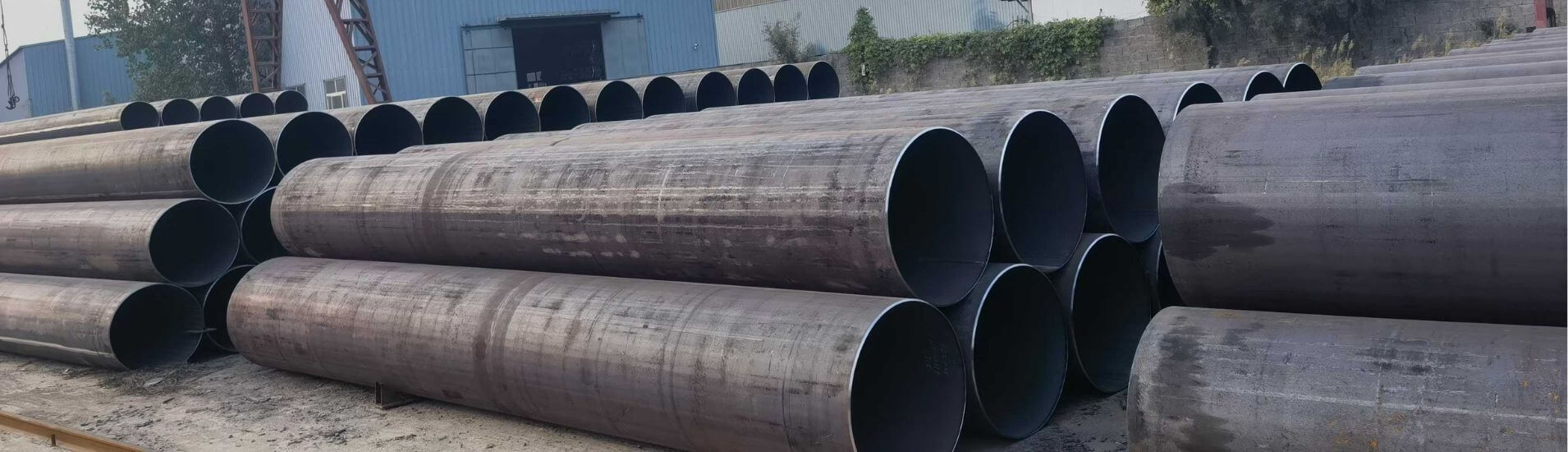

Oil Well Conductor Pipe Are Products Used In The Oil Extraction Process, And We Can Also Understand Them As Large-Diameter Pipes. Balingsteel Has 25 Years Of Professional Experience In The Steel Industry And Can Provide The Following Different Types Of Conductor Pipes For Your Oil Projects:

Conductor Pipe In Drilling

Oil And Gas Conductor Pipe Market

Balingsteel Is A Chinese Supplier Of Conductor Pipe, Casing And Tubing, Which Can Provide You With A One-Stop Solution To Your Oil And Gas Extraction Equipment Needs. According To Insight Business Research, Global Pipe Demand Will Continue To Grow Until 2033. Balingsteel Will Strive To Become A World-Class Conductor Pipe Supplier During This Period. Please Feel Free To Contact Us For Cooperation.

What Is Conductor Pipe

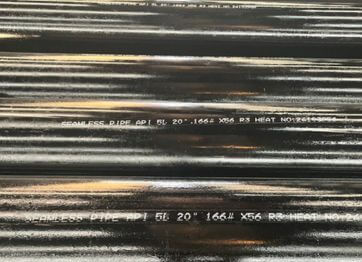

In The Process Of Oil Extraction, Oil Well Conductor Pipe Is Used. It Is The First Product Used In Oil Drilling. It Mainly Plays The Role Of Fixing And Preventing Wellhead Collapse, And Provides A High-Quality Construction Environment For The Subsequent Laying Of Oil Casing And Oil Pipe. Common Oil Conductor Pipe Materials Are Api 5l B, X42, X46, X52, X56. Balingsteel Can Quickly Provide You With A Large Number Of Oil Well Conductor Pipes And Send Them To The Nearest Port Within 7 Days.

Conductor Pipe Size

Baling Steel Can Provide You With The Following Popular Sizes:

| Outside Diameter (OD) | Wall Thickness (WT) | Grade | Product Type | Connection | FOB Price (USD/Ton) |

| 18″ | 0.375″ | X56 | Welded&Seamless | Beveled&Plain End | 870 |

| 20″ | 0.500″ | X56 | Welded&Seamless | Beveled&Plain End | 895 |

| 24″ | 0.500″ | X56 | Welded&Seamless | Beveled&Plain End | 910 |

| 26″ | 0.562″ | X56 | Welded&Seamless | Beveled&Plain End | 935 |

| 30″ | 0.625″ | X56 | Welded&Seamless | Beveled&Plain End | 980 |

| 36″ | 0.750″ | X56 | Welded&Seamless | Beveled&Plain End | 1020 |

| 42″ | 1.000″ | X56 | Welded&Seamless | Beveled&Plain End | 1080 |

In Addition, We Can Also Customize The Size According To Your Requirements, Welcome To Inquire.

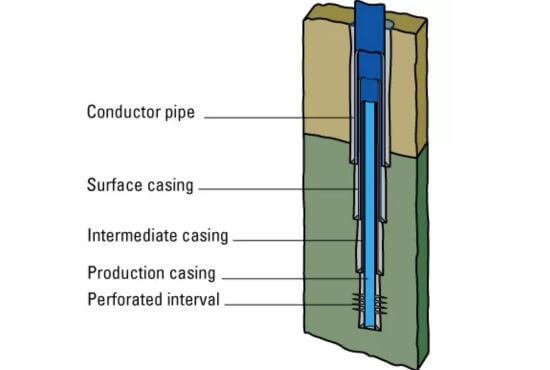

The conductor pipe is a pipe product used for fixing, supporting and subsequent work in oil well installation.

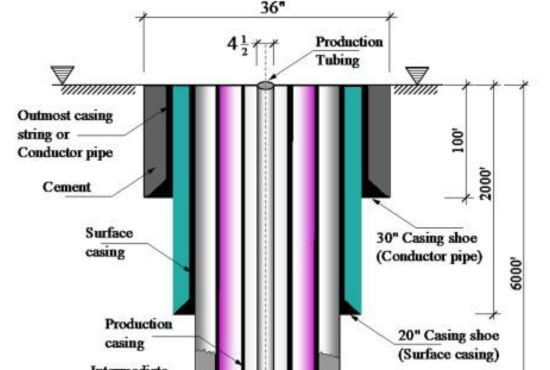

In oil and gas drilling, it is a steel pipe buried in the wellhead and used to stabilize the upper part of the well. The size usually ranges from 18 inch to 30 inch.

It is mainly to prevent the soil collapse at the wellhead and protect the normal operation of the equipment.

- The conductor casing is mainly used to support the wellhead and the base of the blowout preventer, protect the loose soil, and prevent the loss of drilling fluid.

- The surface casing is mainly used to support the base and the deep casing to protect the integrity of the aquifer and formation.

The purpose of steel casing is to isolate and protect the different conditions and conditions inside and outside the steel pipe.

When using and placing oil drilling or water wells, it will cause pollution to the wellhead, so we need casing for isolation and protection.

PVC pipes can be used as conduits for water wells.

Yes, for different construction environments, aluminum pipes can also be used as conduits, but the cost of use will be higher.

Yes, most conduits are made of metal, usually carbon steel, such as API 5L X56 PSL 1.

It is a pipe that fixes and supports the wellbore.

Before drilling begins, the conductor is driven into the ground to protect the soil and the recycling of drilling fluid.

Isolate the soil from pollution and make full use of the recycling of drilling fluid.

The conductor pipe can be a welded pipe or a seamless pipe.