In oil and gas operations, the choice of casing and tubing pipes is a very important factor for achieving efficiency, safety, and the best performance. Of all the grades standard API 5CT to the most commonly used, J55 and K55 have different properties and applications but they are still very much alike at some points. However, what factors to consider when choosing one over the other for your particular needs? This guide reveals the main differences and similarities between J55 and K55 casing and tubing pipes, and it is loaded with tips for you to make the right choice. No matter if you are looking for cost, durability, or operational needs to be met, knowing these differences is a must for the success of the project.

Introduction to Casing and Tubing

Casing and tubing are very important parts in the process of drilling oil and gas with a rig, where each of the two has its own function but still supports the other. Casing is the material that forms the wellbore wall; it is also the structural support for the whole well and the barrier between different mineral strata. The tubing is the one that goes inside the casing and carries the oil and gas in an area that is safe to the surface. Materials for both are often selected based on their criteria of being efficient, safe, and lasting with the well.

Definition of Casing and Tubing

Casing is a wide pipe that serves to support the wellbore, to prevent it from collapsing and to separate the various underground layers.

Tubing is a narrow pipe inserted into the casing that has been purposefully made to quickly carry the produced oil and gas to the surface. The two parts are critical for well integrity and safe resource extraction.

Importance in the Oil and Gas Industry

Casing and tubing hold a pivotal position in guaranteeing the safety, efficiency, and durability of oil and gas operations. Casing gives the wellbore a robust structure, thus preventing any collapse and reducing the chances of any contamination between the layers of earth. Tubing guarantees that the hydrocarbons are moved to the surface in an efficient manner which again optimizes production while minimizing the risks. These components, together, are the mainstay of the well and hence the sustainable development of the resource.

Overview of API 5CT Standards

The American Petroleum Institute has set the API 5CT standards in order to determine the requirements for casing and tubing utilized in the oil and gas industry. These standards include the whole process from manufacturing, testing, marking, and finally, inspecting steel pipes to make sure that they have the desired properties, are suitable, and will perform under changing operational conditions. Operators who comply with the API 5CT standards will not only boost well integrity, but also guarantee safer operations and help the extraction of resources become more efficient.

Understanding J55 and K55 Grades

J55 and K55 are two steel grades that are considered the best ones for casing and tubing in the oil and gas industry, and even more so, they are characterized by API 5CT standards. Their main characteristics are trustworthiness and moderate depths and pressures as the primary installations.

J55 Grade

J55 is the cheapest alternative that is acceptable for less demanding operations. Its minimum yield strength of 55,000 psi makes it a perfect choice for shallow wells, where high pressure and temperature are not significant difficulties.

K55 Grade

K55’s physical properties are the same as those of J55 but it has slightly higher strength, thus better resistance to collapse and burst pressures. That is why it is a more suitable option for wells with slightly more adverse conditions.

The two grades have the same chemical compositions but their performance varies according to the exact operational requirements. It is necessary to carefully evaluate the well conditions when making a choice between J55 and K55 to ensure both safety and efficiency.

Overview of J55 and K55 Steel Grades

Steel grades J55 and K55 are among the most commonly used for casing purposes, with a major application in the oil and gas industry. They have similar chemical compositions but their mechanical properties vary to some degree. K55 is stronger and more resistant to both collapse and burst pressures than J55, which is why K55 is the stronger option for moderately demanding wells. A decision between the two needs to be based on an assessment of the specific operational requirements in order to guarantee safety and performance at the best possible level.

Mechanical Properties of J55 vs K55

J55 and K55 share almost identical chemical compositions; however, they are different in terms of mechanical strength and performance. K55’s minimum yield strength is 95 ksi which is higher than J55’s 75 ksi, thus giving K55 better resistance to collapse and burst pressures. What is more, K55 has superior tensile strength which makes it more suitable for moderate to heavy drilling conditions. J55, conversely, is more frequently utilized in less arduous environments because of its adequate performance and low-cost. The selection of one over the other should depend on the specific operational and environmental conditions of the well.

Applications of J55 and K55 Casing

The usage of J55 and K55 casing for wells is decided by the operational needs and the well conditions. The main application of J55 casing is in shallow wells characterized by low to moderate pressure such as freshwater, coalbed methane, or geothermal wells, where, among many factors, cost-effectiveness prevailing is the most important one. Unlike K55 casing which is limited to these conditions of pressure and temperature, it can be used in deeper wells or higher pressure and temperature areas, thus providing strength and durability that can withstand even the most demanding conditions. The right casing choice guarantees not only perfect performance but also long-lasting drilling process reliability.

Comparison of J55 and K55 Casing

The core distinction that separates J55 from K55 casing is their respective tensile strengths along with stress performance. K55 has a tensile strength that is greater than J55 thus making the latter more suitable for wells that have higher pressures or operate under more challenging conditions. Both grades are similar in terms of their chemical compositions, however, K55’s strength has been augmented so as to be able to support greater workloads thus enabling it to remain durable and reliable in harsh environments.

Conversely, J55 is a budget-friendly alternative and has a good performance in less strenuous situations like shallow wells or low-pressure cases. The decision of picking between J55 and K55 should depend on the actual well conditions and consider the factors of depth, pressure, and environmental stress to get the maximum performance and safety.

Key Differences between J55 and K55

- Strength Characteristics:

K55 has higher tensile strength and yield strength compared to J55, making it suitable for more demanding applications - Application Suitability:

J55 is ideal for shallow wells with low pressure; K55 is designed for moderate depth and pressure applications - Cost Factor:

J55 is more economical; K55 commands a higher price due to enhanced performance characteristics - Durability:

K55 offers better resistance to collapse and burst pressures, ensuring longer service life in challenging conditions

Performance in Different Environments

K55 is an absolute powerhouse in high-pressure, high-depth environments where durability is a major factor. The material’s tensile strength and toughness allow it to withstand very harsh operational conditions. On the other hand, J55 is, however, a better option for environments that are not so demanding, like shallow wells, or in places that have lower pressure requirements, giving an economical and efficient solution that still has the performance standard adequate for these conditions.

Cost Analysis of J55 vs K55 Casing

In general, when taking a look at cost references, the J55 casing material is considered to be economic, in comparison to the K55, because of the latter’s challenging applications. This likens it to be the cost-effective pick for the operations with the least strict specifications. Meanwhile, the K55 casing is a bit superiorly priced, given it has more tensile strength and endurance; both very necessary for the high pressure or, deep-well conditions. The choice of material between J55 and K55 must consider the price of one with the other. It will reduce the cost of the equipment and will supply the same or even better performance.

API 5CT Casing and Tubing Specifications

API 5CT guideline serves to standardize tubing and casing both industries of oil and gas to make sure that the specificity of the operations is met with the highest quality and consistency for all manufacturers. The most crucial and required factors are the materials being used, how they perform in terms of mechanical properties, and the standard requirements of the performance in various environments of the well. The necessities in API 5CT are:

- Material Grades: There are several common grades with J55, K55, N80, and P110 being among the most known ones, each of them designed for specific pressure and temperature conditions.

- Mechanical Properties: Minimum yield strength, tensile strength, and hardness are among the properties to know when dealing with the operation stresses.

- Dimensions: Outer Diameter ranges from 4.5 inches to over 20 inches, and Wall Thickness varies reflecting the varying pressure range for the well infrastructure.

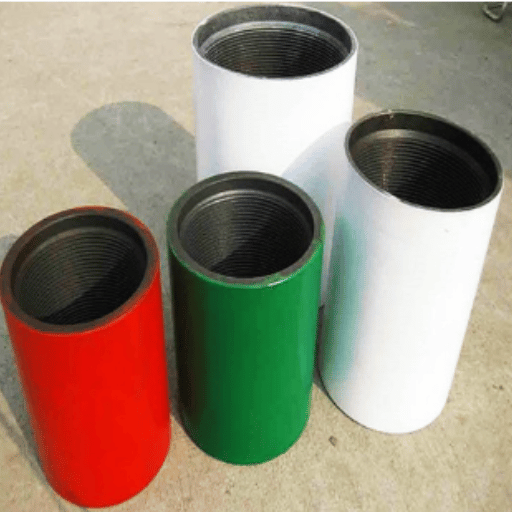

- Thread Connections: API standards include LTC (Long Thread Coupling), STC (Short Thread Coupling), and BTC (Buttress Thread Coupling) ensuring joints are both safe and not leaky.

- Testing and Certification: All products undergo hydrostatic pressure, impact, and hardness testing to satisfy performance stipulation.

Understanding API 5CT specifications is a must for choosing safe, durable, and operationally efficient casing and tubing.

API 5CT Casing Pipe Specifications

Specifications for API 5CT casing tubing cover a plethora of parameters that are required for the use of the product in various oil and gas wells. These may include the specifications of the material and the strength grades as J55, K55, N80, L80, P110, and Q125 that are different in level and the resistance to corrosiveness. In addition, sizes of pipes matched with standard outside diameters, wall thicknesses, and limits would achieve different well conditions while honoring API rules. Connections such as LTC, STC, and BTC prevent leaks, and each one of the pipes is subjected to strict testing involving hydrostatic, impact, and hardness records. These exams are such that they are to identify the conformity with the API 5CT standards and for the pipes to be safe in the operation.

Understanding PSL1 and PSL2 Requirements

API 5CT has PSL1 (Product Specification Level 1) and PSL2 (Product Specification Level 2) as two of the standards’ classes that specify the quality levels and testing requirements for casing and tubing used in oil and gaswells at different levels. The PSL1 represents the standard quality level, the basic testing requirements of which make it suitable for almost all applications. PSL2, on the other hand, the demands imposed have higher quality controls including also chemical composition limits and considerably more mechanical testing. This standard also requires that the material be reheated and heat-treated. This makes PSL2 not only ideal for those critical operations where a high level of performance and reliability partnering is needed but by all means one that is all very much required. As to the question of PSL1 and PSL2 for the project, it should be assessed based on the specific project needs, environmental conditions, and operational demands.

Comparison of API 5CT Grades

API 5CT grades have been classified according to material composition, mechanical properties, and their primary use cases. These are the usual grades: J55, K55, N80, L80, and P110, with each grade serving distinct operating conditions. It is worth mentioning that J55 and K55 are preferable if you are in a low-pressure situation, both being the most cost-effective among the API 5CT grades, whereas L80 and P110 are the API 5CT grades that are to be used in the highest pressure and sour service conditions because of their higher than average strength and corrosion resistance. The durability and operating efficiency of a product largely depend on the choice of the grade in terms of variables such as pressure, temperature, and the presence of corrosive elements.

Frequently Asked Questions (FAQs)

Reference Sources

- World Iron Steel – Difference Between K55 and J55: It explains the differences between the casing pipes as well as their applications, also stating that they are low cost choices for wells having not so strict requirements.

- ZC Pipe – Understanding J55 Vs K55 API 5CT Casing Pipe: This helps the reader to notice the main differences between the two with greater focus on their oil and gas sectors use.

- Continental Steel – API-5CT Casing Steel Grades: Just gives a brief on API-5CT casing steel grade and the two steel grade involved and the role they play in the oilfield application.

- Octal Steel – API 5CT J55/K55 Casing and Tubing Pipe Specification: Elaborates on the specifications, uses, and benefits of J55 and K55 casing and tubing.

- The SCX Change – J55 vs K55 Casing Pipe: Here the conversation is around the mechanical properties and difference in the tensile strength and elongation of J55 and K55.

Conclusion

Choosing between J55 and K55 casing and tubing pipes is a critical decision that directly impacts the safety, efficiency, and cost-effectiveness of oil and gas operations. While both grades share similar chemical compositions and comply with API 5CT standards, their mechanical properties and performance characteristics make them suitable for distinctly different applications. J55 offers an economical solution for shallow wells and low-pressure environments, while K55 provides enhanced strength and durability for moderate-depth wells and higher-pressure conditions. By carefully evaluating factors such as well depth, pressure requirements, environmental conditions, and budget constraints, operators can make informed decisions that optimize both performance and cost. Understanding these differences ensures not only the success of your project but also the long-term integrity and reliability of your well operations. Always consult with industry experts and adhere to API 5CT specifications to guarantee safe and efficient resource extraction.