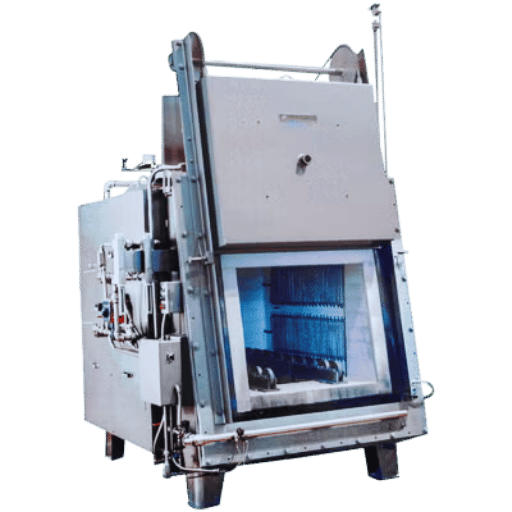

Modern manufacturing and material processing rely heavily on industrial annealing ovens, which optimize the performance of materials and products. These annealing ovens are sophisticated and tailored to meet industrial demands as they enhance the strength of metals, relieve stress, and improve elasticity. However, what is the reason for their immense dependence? What are their functions? Moreover, what are their distinguishing features? This guide will walk you through the workings of industrial annealing ovens, their numerous applications, as well as help you choose or refine your tool according to your needs. If you are an industry expert or even just inquisitive about the technology behind modern production, you will find everything you want to know here.

What is an Annealing Oven and How Does it Work?

An annealing oven is an industrial device that heats metals, glasses, and other polymers to specific temperatures and cools them at controlled rates. These materials undergo a process called annealing, which helps reduce internal stresses, improves ductility, and enhances overall material strength. An oven achieves the required results by using precise temperature control to maintain uniform heat distribution through the material. The uniform heating enables the material’s microstructure to realign, which provides the intended mechanical attributes. Ovens of this type are critical in modern industries that require high-quality and durable materials for manufacturing and production processes.

Understanding the Annealing Process in Ovens

Annealing in ovens is a form of heat treatment involving heating metal, glass, or plastic to relax internal stresses, change their microstructure, as well as enhance the material’s properties, such as its ductility and strength.

The Role of Heat and Temperature Control in Annealing

The most crucial factors regarding the microstructure and mechanical properties of the material are temperature and heat, which are the primary components of the annealing process. It is said that different materials being treated require a particular type of heater, called the recrystallization heater, that maintains specific energy levels associated with material type. The application of heat is controlled in a manner that provides undesired molecular movements, also termed as ‘dislocations’, within the material known to occur due to build-up of energy devoid of external forces realignment in a material denotes a process of injury recovery, termed ‘recovery processes’; and staff realign or relieve internal stress.

Since industries are known to rely on programmable real-time monitoring devices, more often than not, the mentioned devices offer novel technologies exclusive for perennial temperature, and advanced technologies offer modern solutions that guarantee temperatures at specific points through the annealing process. Such developed technologies provide clear results, enhance the efficiency of the entire procedure, and provide exquisite outcomes, especially in materials assembly precision. It is said that with advanced control at height, the manufacturer maintains programmed heating and controlled cooling rates, the intended material associated with high strength but low ductility proves to maintains structural integrity while being extremely durable.

Types of Industrial Ovens for Annealing

| Type | Heat Source | Temp Range | Airflow | Use Case | Size |

|---|---|---|---|---|---|

|

Batch |

Electric/Gas |

Up to 950°F |

Static |

Small batches |

Variable |

|

Continuous |

Electric/Gas |

Up to 1200°F |

Dynamic |

High volume |

Large |

|

Conveyor |

Electric/Gas |

Up to 1000°F |

Forced |

Mass production |

Large |

|

Forced Convection |

Electric/Gas |

Up to 572°F |

Circulated |

Uniform heating |

Medium |

|

Natural Convection |

Electric |

Up to 300°C |

Natural |

Sensitive loads |

Small-Medium |

|

Vacuum |

Electric |

Up to 482°F |

None |

Oxidation-free |

Small-Medium |

How Does the Annealing Process Benefit Various Industries?

Annealing Metal and Its Mechanical or Electrical Properties

The annealing process enhances the ductility of metals, reduces their hardness, relieves internal stress, improves machinability, and may also increase electrical and magnetic susceptibilities.

| Property | Effect | Details |

|---|---|---|

|

Ductility |

Increased |

Restores flexibility |

|

Hardness |

Reduced |

Softens material |

|

Stress |

Relieved |

Removes internal stress |

|

Machinability |

Enhanced |

Easier to shape |

|

Conductivity |

Improved |

Better electrical flow |

|

Magnetism |

Enhanced |

Improves magnetic properties |

The Impact of Annealing on Plastic and Glass

Annealing is essential in improving the characteristics of plastic and glass. In case of plastic materials, the process reduces internal stresses due to molding or extrusion, which tend to warp, crack, or fail under load. It also improves dimensional stability, increases clarity in some polymers, and improves visibility.

In the case of glass, the annealing process removes residual stresses generated during the cooling stage of production. This minimizes the chances of the material breaking or shattering easily when subjected to temperature changes or mechanical forces, thereby improving strength and durability. The amount of both materials is significantly enhanced by the use of annealing, due to increased reliability and longevity in applications.

Applications of Annealing Furnaces in Industry

- Metalworking Industry: The Primary function in annealing processes is to make steel, aluminum, and copper softer to improve ductility and prepare them for further machining or shaping processes.

- Glass Manufacturing: Essential for removing internal strains from glass bottles, window glasses, and even optical components to ensure durability and consistency.

- Polymer Processing: Applied in the manufacture of some plastic materials to enhance their internal structure, clarity, and mechanical properties.

- Electronics Industry: This is applied in the kinds of processes that involve annealing semiconductor parts to improve their structure and electronic functions.

- Automotive Sector: Central to the production and processing of parts such as gears, shafts, and body panels to guarantee their strength and reliability standards.

- Construction Materials: Uses annealing processes for structural materials such as beams of steel and pre-stressed glass to improve safety and longevity in engineering applications.

- Tool Manufacturing: Focused on Hand tools, cutting tools, and industrial dies are refined with heat to improve their accuracy and endurance.

- Aerospace Industry: Vital for operating high-tech alloy components made of composites, which are lightweight yet exceptionally strong and which must endure extreme operational conditions.

What are the Different Types of Annealing Furnaces Available?

Exploring Programmable and Custom Annealing Ovens

Like metals, plastic, and glass, materials require definite temperature management for precise treatment. Programmable and custom annealing ovens are tailored heating systems that are designed to meet such challenges with automation control, custom settings logic, and uniform heating capabilities, providing for the varying needs of industries.

Comparing Convection and Forced Convection Ovens

In convection ovens, heating is achieved through natural circulation of the air, whereas in forced convection ovens, a fan is used to distribute heat evenly and expedite drying.

|

Parameter |

Convection Oven |

Forced Convection Oven |

|---|---|---|

|

Heat Source |

Natural air |

Fan-assisted |

|

Heat Uniformity |

Moderate |

High |

|

Drying Speed |

Slower |

Faster |

|

Energy Use |

Lower |

Higher |

|

Cost |

Economical |

Expensive |

|

Applications |

General |

Precise |

|

Maintenance |

Simple |

Moderate |

How to Choose the Right Oven for Your Annealing Needs?

Key Features to Look for in an Industrial Annealing Oven

- Oven Thermal Accuracy: Ensures a consistent range of temperature across the entire oven area, which is crucial for achieving uniform heating during annealing.

- Fine Engineering: Increases the temperature to the required degree of any process or material to be treated within the oven.

- Long Term Operational Reliability: Constructed from resilient materials that can endure high temperatures and extensive use, ensuring longevity, reliability, and safeguarded operational safety.

- Low Energy Consumption: Implemented means that alter energy utilization without compromising operational efficiency and performance.

- Automated Safety Features: Advanced protection mechanisms designed to maintain the safety of both the personnel and the machine, such as alarms and power cut-off systems.

- Adjustable Chamber Dimensions: Available for chambers of different sizes to fit varying batch amounts or samples to be processed.

- Low Maintenance: Enhanced design for cleaning and repairing to ensure minimum operational downtime.

- Automated Processes: Precision-engineered controls for advanced process programming that increase precision and workflow efficiency.

- Multiple Industrial Uses: Capability to process a wide variety of materials like metals, glass, and polymers, thereby increasing the scope of industrial applications.

- Industry Compliance: Following stipulated legal demands and industry policy benchmarks defined regarding safety, performance, and eco-friendliness standards.

Understanding Temperature and Controller Options

The temperature and controller settings are key elements in today’s industrial systems, providing effective thermal management as well as dependable operation. The latest temperature controllers make use of programmable control algorithms, adaptive control techniques, and integrated sensors for maximum optimization of operation. Moreover, these systems are often compatible with PID (Proportional-Integral-Derivative) control, thus providing accuracy in temperature control even at fluctuating ambient conditions.

While selecting temperature controllers, it is crucial to determine the selection criteria, such as the range of temperature, time of response, and the system’s alignment with materials and processes. Advanced controllers also feature integration with other IoT components for instantaneous tracking and monitoring, real-time changes, or even remote updates on the system’s processes via cloud systems, including Google’s analytical platform, which employs machine learning. Such modern technological devices enhance energy savings, prolong the operational lifetime of serviced equipment, and meet compliance requirements of normative US standards: ISO and ANSI. Thus, using those allows remarkable enhancement of performance as well as reduction of costs during production and other industrial activities.

When to Consider Walk-in Ovens for Large-Scale Annealing Applications

- High-Volume Production Requirements: Walk-in ovens are excellent for plants that have to process a lot of materials at once because they guarantee that all materials receive the heat treatment in a consistent and thorough manner.

- Oversized or Heavy Components: These ovens are particularly suited for rough machining these bulky, oversized, or heavy workpieces, as they cannot be accommodated in smaller ovens.

- Custom Temperature Specifications: Walk-in ovens can be set to execute processes within certain bounds owing to their advanced programmable features, which guarantee accuracy in imposing the desired range of precise and controlled temperatures for material manipulation.

- Batch Uniformity and Quality Standards: For sectors such as aerospace or automotive, where there is intense and unyielding quality control, consistency and compliance with overall walk-in ovens features key specifications guarantee sufficiency.

- Energy Efficiency in Large Scale Operations: For advanced facilities, modern walk-in ovens offer greatly integrated efficiency savings concerning energy use while upholding performance needs through high-end insulation aids, conserving energy during peak operational times.

- Flexible Loading/Unloading Requirements: These ovens are ideal for operations where large or oddly shaped items need to be effortlessly loaded and unloaded with forklifts and other handling equipment.

What are the Safety and Maintenance Tips for Operating Annealing Ovens and Furnaces?

Ensuring Heat and Temperature Safety

To guarantee the safe and operational upkeep of an annealing oven or furnace, one must carry out routine servicing such as inspection and cleaning, ensure exhaust and ventilation requirements are met, enforce appropriate temperature control and monitoring, comply with PPE relating to the equipment being worn, safekeep the defined mechanical and electrical systems, and practice preventative maintenance strategy.

Regular Maintenance for Longevity of Annealing Ovens

To prolong the life of the annealing ovens, I focus on a few key maintenance activities. Performing regular cleaning and examination of the interior prevents the accumulation of residues that might hinder performance. Proper calibration of temperature controllers guarantees energy-efficient operation along with reliable metered output. As a matter of routine, I inspect the electrical and mechanical parts and, if necessary, replace the faulty parts to maintain operating reliability without unwanted interruptions. Following the specific plan for scheduled maintenance activities allows me to detect any potential equipment issues at an early stage, ensuring the equipment is suitable for prolonged use.

Handling Internal Stress and Stress Relieving

To operate and maintain the ovens and furnaces used for annealing, thorough cleaning, inspection, and calibration, alongside protective equipment and proper ventilation, is necessary. Adhering to the manufacturer’s guidelines prevents internal stresses while achieving effective stress relief.

Frequently Asked Questions (FAQs)

Q: What is the Primary Role of Industrial Annealing Ovens?

A: Industrial ovens are the ovens used for annealing, a process of heat treatment for materials that necessitates heating and cooling processes of materials. It is beneficial in metal materials to increase ductility, decrease internal stresses, and effectiveness in functionality during the use of metal parts.

Q: How do Annealing Ovens Aid in the Glass Annealing Operation?

A: Annealing ovens in glass annealing are used to provide unevenly heated chambers that gradually lower, which slows down the cooling process. This slow temperature decrease strengthens internal stresses as well as eliminates chances of cracking, hence providing durability and lucidity to the glass.

Q: What are the Heating Features of the Annealing Ovens to Achieve the Recommended Value in Temperature Uniformity?

A: The failure and the success of ovens in the tempering of annealing ovens depend greatly on the enhancing features. Such as having all the necessary add-ons, measurement, and space controlling systems that are put in the heating chamber for the tempering to provide the necessary conditions, must then function with accurate control and even distribution of the heating elements for tempering to be successful.

Q: Why is the slow cooling step important in the annealing process?

A: Slow cooling is especially important because it allows the change of the microstructure of a material to happen gradually without the release of internal stresses. The improvement of the ductility and reduction of the hardness of the material is achieved through this transformation process.

Q: In what ways do materials differ in their temperatures used for annealing?

A: There is variation in materials when it comes to temperatures used for annealing. For instance, glass may require lower annealing temperatures than metals. The specific temperatures depend on the anticipated microstructure and the mechanical attributes that are aimed to be achieved in the final product.

Q: What is the function of annealing batch ovens, and how are they different from other ovens?

A: These ovens are tailored to work with materials in fixed amounts or batches. They maintain an ideal environment during the heating and cooling stages for each batch to ensure consistency and uniform processing. This contrasts with continuous ovens that treat materials without interruption as a singular stream.

Q: In what way can the processes involved in heat treatment influence the microstructure of metals?

A: Heat treatments such as annealing influence the microstructure of metals by changing the positioning of atoms, as well as the scale of the grains within the metal. This Alteration fosters improvement in metals’ ductility, toughness, and hardness, thereby preparing it for further manufacturing processes.

Q: What is the function of filaments in an annealing oven?

A: Filaments in an annealing oven serve the purpose of supplying intense heat, which is essential for the heat treatment processes of metal components. The heat energy they provide is essential for the formation of the microstructure of the components, enabling the desired mixture of mechanical properties.

Q: Is there a range of industrial annealing ovens in different designs?

A: Of course, there are industrial annealing ovens that are specially designed to suit the needs and materials of various industries. From small batch ovens to large-scale continuous systems, each design offers a different advantage in terms of capacity, efficiency, and control of the processes.

Reference Sources

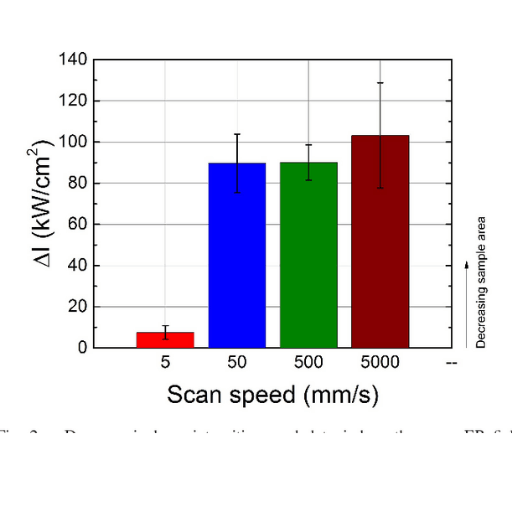

1. Photonic Drying/Annealing: Influence of Oven, Visible Light, Infrared, Flash Lamp, on Drying or Annealing of WO3 for Electrochrome Smart Windows

- Authors: K. Mallikarjuna et al.

- Published on: November 1st, 2021

- Journal: ACS Sustainable Chemistry & Engineering

Research Highlights:

- The focus of the study is to understand the impact of etching and drying processes on the electrochromic smart windows tungsten trioxide (WO3) films.

- Comparison to traditional methods was made, such as oven drying versus drying using visible or infrared light.

- Findings demonstrate that the selected method of annealing alters the electrochromic properties of WO3 films and thus their suitability for integration into smart windows.

Research Approach:

- The authors applied different etching and drying processes and characterized the films electrochemically and optically (Mallikarjuna et al., 2021, pp. 14559–14568).

2. Improving the performance and consistency of CH3NH3PbI3−xClx perovskite solar cells by an air-heated oven-assisted annealing technique at different humidities

- Author(s): Qing Zhou and others

- Publishing Date: February 16, 2016

- Journal: Scientific Reports

Summary:

- The article claims that the air-heated oven annealing technique is capable of producing better and more uniform films in comparison with hot plate annealing.

- The research results demonstrate that the oven process enhances the power conversion efficiencies of the perovskite solar cells.

- The conclusion suggests that the step of annealing is important when aiming to obtain good-quality perovskite films that are needed in efficient solar cells.

Approach:

- The authors performed the experiments at varying humidity levels and analyzed the solar cells from different annealing methods, using the oven method of soldering(Zhou et al., 2016).

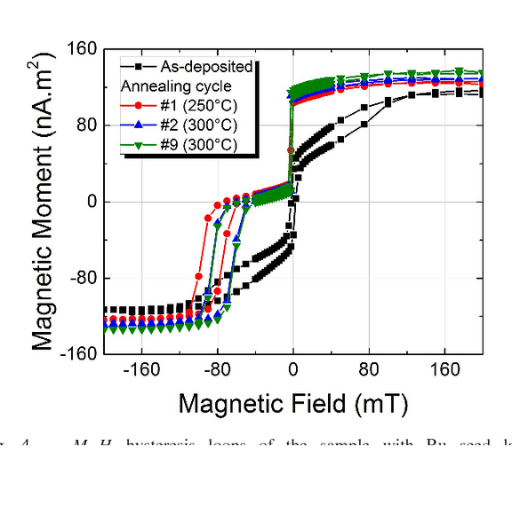

3. Magnetic Tunnel Junctions: Laser vs. Oven Annealing

- By: Apoorva Sharma and colleagues

- Published: 2019

- Source: IEEE Transactions on Magnetics

Major Takeaway:

- This study investigates the impact of both laser annealing and conventional oven annealing on the functionality of CoFeB/MgO tunnel junctions.

- The investigation concludes that laser annealing is beneficial for managing process scalability and enabling transverse magnetization configuration.

- The findings suggest that laser annealing enhances the magnetoresistance ratio more than oven annealing.

Research Approach:

- The authors studied the magnetic characteristics of the junctions in the post-annealing period to explain the differences in performance and the mechanisms responsible for them (Sharma et al., 2019, pp. 1–4).

4. Photons: A Non-Thermal Approach To Annealing—Oregon State University: Explores different annealing techniques, such as oven heating for stimulating chemical and phase reaction changes in materials.