Butt weld fittings are an essential component in many industrial applications, serving as the backbone for creating robust, reliable, and functional piping systems. Whether you are in the oil and gas sector, chemical processing, or power generation, understanding these fittings is paramount to their effectiveness and structural correctness. In this presented context, super acidity provides plenty of information on butt weld fittings starting from the different types, and the raw materials used to construct them, to the extent of their application and their flips. Geared towards bridging both theoretical and practical aspects of butt weld fittings, this article seeks to demystify butt weld fittings, as well as empower you with the adequate skills to apply them appropriately to humane smart decisions about your specific engagements. Continue reading to dig deeper and get answers regarding those very essentials.

What are the Different Types of Butt Weld Fittings?

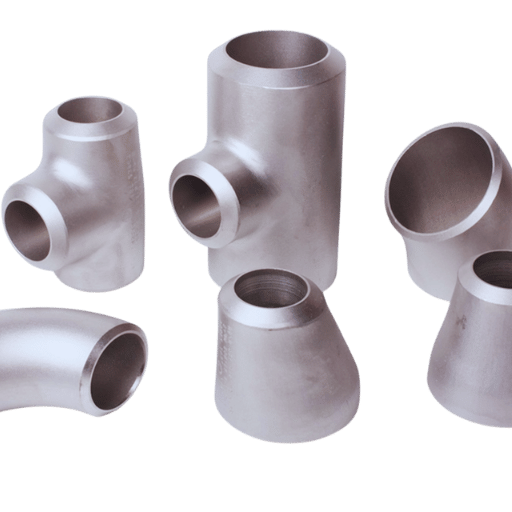

- Elbows: Used in flow-line systems as turnpoints. Generally come in 45-degree, 90-degree, and 180-degree configurations.

- Tees: This fitting allows the division or confluence of fluid flow and the full or partial dismantling of pipes.

- Reducers: These fittings transition the diameter of two pipe sections and are sold concentrically or eccentrically.

- Caps: Are used as end closures to tighten the end faces to prevent leakage.

- Crosses: These fittings connect four pipes in a single location, which is neurotic at best.

Understanding the Elbow Variants

Elbow fittings are indispensable in a network of pipes when the direction of fluid flow needs to be altered, which is commonly done at angles like 45°, 90°, and 180°.

- 45° Elbows: They redirect the flux at a slight (and symmetrical) angle, effectively reducing resistance and the non-uniform pressure drop within the system.

- 90° Elbows: They are frequently used, especially where a sudden flow direction change is required without much space.

- 180° Elbows: This component facilitates complete flow inversion, a feature often contributed to U-bendings and flow looping applications.

Every fitting has various operational capabilities and incorporates the system’s efficient functionalities and physical integrity. A client’s correct choice regarding the specified angle and purpose will ensure the best results in a given installation.

Exploring Tee Connections

Tee connections are pipe fittings that direct fluid flow from a single source into two, mainly opposite directions or paths. Typical configurations are equal tees and reducing tees. Equal tees have three similarly sized openings, whereas in a reducing tee, one branch is larger than the other. Tee connections are mainly used for fluid flow direction or distribution within a system. The proper tee connection can ensure the appropriate flow levels and help counter issues such as pressure imbalances.

Types of Reducers in Butt Weld Fittings

|

Type |

Shape |

Axis |

Use Case |

Material |

Pressure |

Corrosion |

|---|---|---|---|---|---|---|

|

Concentric |

Funnel |

Aligned |

Vertical pipelines |

Steel/Alloy |

High |

Resistant |

|

Eccentric |

Offset |

Non-aligned |

Horizontal pipelines |

Steel/Alloy |

High |

Resistant |

How to Choose the Right Butt-Weld Fittings for Your Project?

Factors to Consider in Weld Selection

- Material Compatibility: Consider the situation of corroding or designing for life, make sure the fitting material for example butt weld fittings matches the pipeline material.

- Operating Pressure and Temperature: Choose fittings that will perform under the prevailing pressure and temperature of the system.

- Pipeline Alignment Requirements: Check and assess if the alignment needs concentric biased or eccentric reducers for the flow.

- Application Type: Determine if the system is intended for horizontal or vertical pipelines, as this would affect the use of the reducer.

- Industry Standards and Certifications: The fittings must comply with relevant industry standards, such as ASTM and ASME, to ensure quality.

Material Compatibility with Stainless Steel and Carbon Steel

Selecting materials with appropriate properties is essential to avoid corrosion, manage structural integrity, and meet performance objectives. One standard mechanical alloy is stainless steel, which contains chromium, enhancing corrosion resistance. This material is widely used in applications where elements like water, chemicals, and often extreme temperatures are present. In contrast, this is circumvented in carbon steels, which offer significant mechanical properties and cost savings.

However, when systems involve stainless and carbon steel pipes and butt weld fittings, galvanic corrosion becomes an issue unless some dielectric material is used to separate the two dissimilar metals which are in contact. Insulating materials such as gaskets, bushings, or other items should be used between the welded pipe and any interior or exterior materials to impede corrosion. Also, using stainless steel type 304 or 316, which are non-aggressive towards carbon steel, will help overcome such a problem.

A further consideration is temperature, as it is understood that stainless steel will usually outperform carbon steel in environments where temperatures are relatively high. However, untreated carbon steel may soften at these higher temperatures and lose strength. Moreover, using protective coatings and cathodic protection may aid in the durability of carbon steel components in systems of various materials. Considering such factors allows for introducing systems using both stainless steel and carbon steel, with the retention of reasonable prices and suitable long-term operation.

What is the Installation Process for Butt Weld Fittings?

Step-by-Step Weld Fitting Procedure

- Preparation and Inspection: At this stage, check each butt weld fitting and other materials, such as the pipes and adapters, crackles, and dents, for any faults and to ensure no corrosion is present. Check the fitting for conformity with the specified drawings and relevant industry standards.

- Cutting and Cleaning: Shorten the length of the pipe according to the order, bevel the ends in preparation for welding, and clean the edges. Thoroughly clean the edges of the pipe ends and inside the fittings, wiping away any dirt, rust, or oil that might affect the quality of the weld.

- Fit-Up and Alignment: Place the butt weld fitting inline with the ends of the pipe and make way for an acceptable alignment followed by a prescribed gap. Clamps, spacers, a laser pointer, and other alignment instruments must be used during this step.

- Tack Welding: With preparation, the fitting and pipe are tack welded to position for multiple joints. This is crucial in maintaining the alignment of the piping system as it provides support and prevents any movement when the welding is conducted in full.

- Welding Execution: Carry out the welding operation by selecting the correct method, e.g., GTAW, SMAW, or MIG, and applying the relevant welding procedure specifications (WPS). Attention must be given to controlling heat input, welding speed, and technique to ensure the desired quality without defects.

Ensuring Pipe Alignment and Precision

- Use of Alignment Tools: Pipe alignment clamps, levels, and laser alignment systems can also help position the two pieces accurately within each other’s ends. Therefore, alignment between the two pieces is maintained throughout the welding process.

- Visual Inspection: In addition, a thorough visual examination should be conducted to ensure that both the pipe ends and any butt weld fittings are well aligned without any potential gaps that can impair the weld performance.

- Secure Joint Stability: Adjustable clamps or tack welds should be used on the pipe to stop it from moving before commencing welding, which could cause misalignment.

- Verification: Devices such as calipers and gap gauges can perform the actual alignment check regarding the other measurements in the specification or tolerance.

Why are ANSI B16.9 Standards Important for Butt-Weld Fittings?

Overview of ASME and ANSI Standards

The American Society of Mechanical Engineers (ASME) and the American National Standards Institute (ANSI) are notable bodies that establish and promote standards that facilitate systems’ safety, reliability, and compatibility in all industrial sectors. There are specific ASME standards related to pressure piping and pressure vessels, such as ASME B31 and its Boiler and Pressure Vessel Codes (BPVC), among others, which are applicable for the design, construction, and inspection of components to be deployed in critical systems. Such standards are vital to minimizing failures during operations that involve severe conditions like high pressure or high temperature.

Conversely, ANSI acts as a certifying authority for standards from different organizations to enable harmonization and uniformity across various industries. ANSI B 16.9 relating to standard butt weld fittings gives yet another illustration of standardization and its role in making piping systems compatible. These specific fittings, forged within the requisite dimensional and strength specifications, play a critical role in achieving correct orientation and placement, minimizing potential leaks, and enhancing the system’s structural integrity, which is a pipe.

Industry segments like oil & gas, power, chemical, civil, etc., cannot function without assiduous following of the ASME and ANSI standards. Not only does such practice save them from regulatory impediments, but it also saves operational expenses by eliminating the obscurity of weld connections of pipe elements, increasing the durability and service life of the components. Updating and addingenda to the standards related to materials, knowledge, and even situations are regularly performed as approximations of these changes over time. The perpetual synchronization of the standards indicates the ASME ANSI dedication to productive industry development with optimal quality contained within.

Benefits of ANSI B16.9 Compliance

Meeting ANSI B16.9 specifications gives pipe-dependent industries several key benefits, including:

- Enhanced Safety: Fittings made to exact measurements and tight tolerances lower the chance of leaks or failures.

- Standardization: Consistent part dimensions ease installation and upkeep by removing guesswork.

- Regulatory Acceptance: Components that match recognized rules clear the approval path in regulated settings.

- Cost Efficiency: Less scrap, fewer breakdowns, and lower upkeep bills stem from reliably made parts.

- Global Compatibility: International specs allow components to fit systems built anywhere, streamlining logistics.

Together, these gains make ANSI B16.9-compliant piping strong, dependable, and suited to productivity and safety.

Common Challenges in Using Butt-Weld Fittings and How to Overcome Them

Dealing with Eccentric and Concentric Misalignments

- Precision Installation: Appropriate measuring tools and alignment fixtures shall be applied during installations to integrate components accurately. This ensures minimization of the offset between joint elements.

- Correct Fitting Selection: Select fittings that are specifically made for the purpose. Concentric reducers shall be used for vertical transitions to avoid fluid entrapment within the pipe, while eccentric reduction shall apply to all horizontal butt weld fitting transitions.

- Regular Inspections: Schedule regular assessments to detect alignment problems early enough and take remedial action, curbing systems’ long-term inefficiency.

- Proper Welding Practices: Make sure that a qualified welder is present to perform the welding process and comply with the appropriate design welding codes to avoid introducing misalignments due to the welded interference.

Managing Tolerance Issues in Piping Systems

Proper pipe fitting work is achieved by understanding simple design measures, following specific quality procedures, and accurately carrying out all installation work. First, the structural elements should be chosen so that their tolerance is greater than or equal to the expected resolution in the real application. Secondly, the work should not be assembled until it has been thoroughly inspected regarding correct dimensions. Lastly, during the process of installation, utilize calibrated instruments along with experienced personnel wherever needed so that the tubing is in perfect shape and position to avoid any discrepancies and any inefficiency of the system tends to arise. This ensures and provides an effective use of the piping system.

Ensuring Sanitary Standards in Production

Maintaining cleanliness in every aspect of production is imperative to achieve consistent quality of products delivered to consumers and to comply with the set standards. One practical measure is the adoption of Good Manufacturing Practices (GMPs), including compliance with regular cleanings, design of hygienic facilities, training of workers, and so on. Clean-in-place (CIP) devices are primarily used in cleaning production equipment due to efficient cleaning and minimum downtime, as industry guidelines propose. Automated CIP systems are shown to be effective by research; when practiced over time, the systems help lower the microbial levels by almost 90 percent, among other efficiencies in the system. In addition, it is essential to assess the high-risk locations, including any contact surfaces, air filtration equipment, and microbial detection with state-of-the-art sensors, to avoid contamination possibilities. Adopting an analytical and transparent Principles approach in managing production will help facilities retain high levels of hygiene and, more importantly, maximise the available resources.

Frequently Asked Questions (FAQs)

Q: What are buttweld fittings, and why are they essential in pipeline systems?

A: Buttweld fittings are pipe fittings used to change direction, branch off, reduce size, or change the pipe diameter. They are important in pipeline systems because they help make an almost perfect connection and offer a lot of strength. They are also pressure—and temperature-resistant, which makes them useful in most industrial piping systems.

Q: How do you differentiate between a 45° and 90° butt weld elbow?

A: The 45° and 90° butt weld elbows differ in the angle at which they bend the pipeline. To explain, a 45-degree elbow will bend the pipe at 45 degrees for smooth curves, while a 90-degree elbow will bend the pipe at 90 degrees for sharp bends in the pipework.

Q: What is the role of a concentric reducer in a piping system?

A: In a piping system, situations might arise where the need to reduce the pipe sizes exists. A pipe fitting, especially a concentric reducer, aligns the centers of the relatively larger and smaller-sized pipes. It reduces the flow through pipe lengths of different sizes and effectively minimizes shock waves in pipes.

Q: Can you explain the usage of a butt-weld lateral in industrial piping?

A: A butt welded lateral, often referred to as a welding lateral, is a special type of pipe fitting which is used to increase the size of the piping system at an angle of 45 degrees. It is often integrated into a more complex piping system to branch out some more pipelines without affecting the overall strength and tightness of the piping.

Q: What are the benefits of using a stub end in flange connections?

A: A Stub end is fabricated when the system is built so that there can be no butt welding at the joint or when there is no access to the rear part of the flange. It is useful as it does not require close tolerances and does not cause distortion. More importantly, it is cheaper since the flanges can be reused during a maintenance check.

Q: How does a reducing tee differ from other buttweld fittings?

A: Torispherical ends are used, namely trepanning, but in this case, reducing tees are used, also known as reducers. One of the three elements is oriented perpendicular to the remaining two, with an outer diameter smaller than the other elements. Such a system is constructed by tees, concentric reducers, and other components to accommodate lower fractions of the flow in the smaller branch.

Q: What factors should be considered when selecting the wall thickness for steel butt weld fittings?

A: In the context of the wall thickness, consideration of the operating pressure, temperature, material of the pipe, possible interactions with the environment, and the life span of the products is expected to vary. The thickness of the walls is usually given in schedule numbers such as schedule 40, 80, etc.

Q: Why is seamless construction significant in carbon steel butt weld fittings?

A: Seamless construction in carbon steel butt weld fittings is essential as it does not comprise welded areas, which can indicate weaknesses of the structure. It is stronger and can depend on it to resist heat and any acidic substances, preventing the risk of leakage. It finds its value in high-pressure and critical applications in industrial piping.

Q: How does the choice of alloy impact the performance of butt weld fittings?

A: The choice of alloy influences the efficiency of butt welds by defining their tolerance to environmental effects such as chemical corrosion, heat, and pressure. Different materials like stainless steel and carbon steel have pros and cons, so using the suitable material with the application in mind is imperative.

Reference Sources

1. Ultrasonic Testing for the Process Piping Butt Weld (2011) (Zhao, 2011)

- According to Zhao (2011), this paper deals with the study of the ultrasonic testing of inspection of process piping butt welds.

- The study reveals the efficiency of ultrasonic testing in locating the defects in the butt weld of welded pipe.

2. International Trade Administration – Stainless Steel Butt-Weld Pipe Fittings

- Provides the scope description and specification of stainless steel butt-weld pipe fittings.

3. Welding

4. Butt welding