In the context of industrial, construction, and engineering sectors, the terms “pipe” and “tube” are more or less used synonymously. However, these components, which appear alike at first glance, have different purposes and are manufactured to different specifications. The distinction between pipes and tubes is important in many fields because their selection influences overhead costs, productivity, and operational efficiency. This document aims to describe these two components—pipes and tubes—in depth regarding their dimensions, materials, applications, and fabrication techniques. This article provides all the necessary information to allow veteran engineers, contractors, or anyone wanting to understand the topic better to make informed choices for their undertakings.

What is the difference between a pipe and a tube?

The distinctions between pipes and tubes arise from their applications, dimensions, and manufacturing practices. A pipe serves the specific purpose of conveying liquids or gases, and is sized according to its internal diameter (ID) and schedule (wall thickness). Tubes are used for structural purposes and are sized according to external diameter (OD) and wall thickness. Furthermore, pipes follow specific industry benchmarks concerning flow rate, whereas tubes observe stricter tolerances on geometry and dimensions, making them more suitable for precision applications.

Key differences between pipe and tube

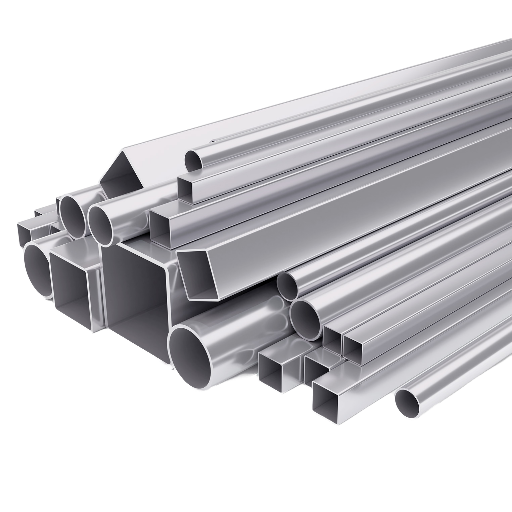

The shape, measurement criteria, application, tolerances, types of materials, and even industrial standards differ between pipes and tubes.

Here’s a short table outlining the distinctions:

|

Parameter |

Pipe |

Tube |

|---|---|---|

|

Shape |

Always round |

Round, square, rectangular |

|

Measurement |

Inside diameter (ID) |

Outside diameter (OD) |

|

Application |

Fluid/gas transport |

Structural/precision |

|

Tolerances |

Looser |

Tighter |

|

Material |

Hot-rolled |

Hot/cold-rolled |

|

Strength |

Lower |

Higher |

|

Size Range |

Larger |

Smaller |

|

Cost |

Lower |

Higher |

|

Flexibility |

Rigid |

Can be bent |

|

Telescoping |

Not possible |

Possible |

Why diameter matters in pipe vs tube

The differences between pipes and tubes are critically important for defining their use in practice. Pipes are aligned with industry regulations and standards, which state that they should be measured by inside diameter (ID) as they are mostly used for the transportation of liquid and gaseous substances. In plumbing systems, oil pipelines, or gas lines, ID is important as it affects flow capacity in systems; hence, efficiency. On the other hand, ID of tubes is rarely used as outside diameter (OD) is used more often because tubes are used mainly for structural purposes. In manufacturing, medicine, and even architecture, where precision external fits and tolerances are essential, OD is of utmost importance to preserve uniformity and consistency.

Some of the most recent data from Google’s search trends show an uptick in queries “pipe diameter vs tube diameter,” which seems to suggest there is increasing curiosity from users, be it companies, firms, or freelancers dealing with these items. Most searches stem from the need to find the correct item for various tasks, reinforcing the notion that it is crucial to even attempt understanding differences, no matter how fundamental. It is easy to see how miscalculated diameter measurements could lead to insufficient fluid flow in pipes and construction, or in some cases, even structural collapse. Hence, while deciding on pipe or tube, the measurement system used in mind should impact its intended use.

How is wall thickness measured in pipe and tube?

To obtain the wall thickness of pipes and tubes, one would measure the outer diameter (OD) and inner diameter (ID), and subtract the latter from the former, then divide the difference by two. The result is usually quantified in inches or millimeters. In terms of measurement, wall thickness is of critical importance due to the strength and durability requirements for specific applications of the pipe or tube. For maintaining precision, I use ultrasonic gauges as well as calipers.

How are pipes and tubes measured?

Understanding nominal pipe size (NPS) and nominal size

Nominal Pipe Size (NPS) and Nominal Size (DN) are both dimensionless standards applicable in marking and identifying particular pipe sizes, with NPS primarily used in North America and measured in inches, whereas DN is the metric equivalent measured in millimeters.

Deciphering the outside diameter and inside diameter

Pipes are typically measured by their inside diameter (ID), while tubes are measured by their outside diameter (OD) and wall thickness.

The role of diameter and wall thickness in determining pipe sizes

The dimensions of a pipe’s diameter and its corresponding wall thickness are of great importance in analyzing its functionality, strength, and flow capacity. Additionally, the inside diameter (ID) is critical for determining the volume of liquid or gas that can flow through the pipe, while the outside diameter (OD) is important in fitting and coupling the pipe. In the same way, wall thickness -often called the pipe schedule number- has an impact on the ability of the pipe to endure pressure and other forces from outside the pipe.

The most recent data and search trends indicate that there is an outstanding gap in piping selection for specialists to fill, owing to professionals’ persistent lack of clarity on how to accurately select pipes for particular applications. The ID and wall thickness are critical in the construction, manufacturing, and plumbing industries where specific flow rates or pressure requirements must be met. A case in point is a pipe with thicker walls, which in certain scenarios will be able to endure greater pressures and harsher conditions, but, due to a reduction in ID, restricts flow. This illustrates the need to understand these relationships for optimizing application-based performance.

What are typical applications for pipe and tube?

When to use a pipe or a tube for gas?

Pipes are commonly employed to convey gases because of uniformity in sizing and emphasis on the internal diameter for volumetric flow rate capacity. On the other hand, tubes are better suited for structural purposes and precise measurements.

Structural applications for hollow section tubing and pipe

- Building Frameworks – Applicable as vertical and horizontal bearing parts in commercial and residential buildings as columns and beams.

- Bridges – Often employed in trusses and other support structures because of their exceptional strength-to-weight ratio.

- Industrial Structures – Used as struts in factory and warehouse buildings, as roof trusses and mezzanine floors.

- Scaffolding – Offers temporary robust platforms and structures for works in construction or maintenance.

- Transportation Infrastructure – Incorporated in the construction of railings and supports for transportation facilities like train and airport stations.

- Canopies and Awnings – Create strong but light frameworks used for shading and weather protection.

- Sports and Recreational Facilities – Commonly used in the equipment and the structures of the stadiums as well as in gyms and playgrounds.

- Machinery Frames – Used for industrial machines and equipment as structural bases and support frames.

- Transmission Towers – Applied in the making of the steel structures for electric and telecommunication towers.

- Fencing and Gates – Used in designing strong and reliable boundary fencing and gates.

The importance of schedule 40 and schedule 80 in different uses

Schedule 40 is best for low-pressure and general-purpose uses. Schedule 80, with its thicker walls, is more durable and is therefore best for high-pressure, industrial, and chemical applications.

| Parameter | Schedule 40 | Schedule 80 |

|---|---|---|

|

Wall |

Thinner |

Thicker |

|

Pressure |

Lower |

Higher |

|

Durability |

Moderate |

High |

|

Cost |

Lower |

Higher |

|

Color |

White |

Gray |

|

Flow |

Less restricted |

More restricted |

|

Use |

General |

Industrial |

|

Weight |

Lighter |

Heavier |

How do material and construction affect pipe and tube usage?

Exploring steel pipe vs steel tube

Steel pipes, which are used in the transportation of fluids, are cost-efficient and measured by their internal diameter. Tubes made of steel are more costly, but are more precise and measured by external diameter. Unlike steel tubes, which have a more versatile shape, they are used for structural purposes.

| Parameter | Steel Pipe | Steel Tube |

|---|---|---|

|

Shape |

Always round |

Round, square, etc. |

|

Use |

Fluid transport |

Structural |

|

Measurement |

Internal diameter |

External diameter |

|

Strength |

Moderate |

Higher |

|

Cost |

Lower |

Higher |

|

Material |

Steel, alloys |

Steel, alloys, others |

|

Tolerance |

Less strict |

Very strict |

|

Length |

Standard sizes |

Customizable |

|

Production |

Mass-produced |

Precision-made |

|

Flexibility |

Rigid |

Can be bent |

The significance of weld and flange in pipe construction

Welding and flanging are vital for pipe construction as they provide durability, reliability, and efficiency for a wide range of industrial applications. Through welding, a pipe section is elevated to a heat or pressure level that is sufficient to join it to another section. This process results in a low-leakage connection and is suitable for high-pressure systems. The system functions effectively due to strong flow and the absence of internal joints or gaps. In contrast, flanging means attaching flat disks or rings called flanges to the ends of the pipe. This makes assembly, disassembly, and maintenance simpler. Flanged connections have great benefits for systems that need regular inspection or reconfiguration, as they easily allow for non-permanent but secure connections.

Searches over the recent years show interest in new pipe construction methods, such as more precise robotic and laser welding. Likewise, newer methods of flange manufacturing, which include better sealing and anti-corrosion materials, are solving problems faced in the petrochemical and energy sectors. The matter of whether to weld or flange is determined by operational needs, budget, and system adaptability, which makes both methods important when creating custom piping systems.

Choosing between stainless steel pipes and other materials

Stainless steel pipes are compared with materials like carbon steel, copper, aluminum, and PVC for their corrosion resistance, durability, cost, and application suitability.

Here’s a concise table summarizing the key points:

|

Material |

Corrosion |

Strength |

Durability |

Cost |

Maintenance |

Applications |

|---|---|---|---|---|---|---|

|

Stainless Steel |

High |

High |

Long |

High |

Low |

Versatile |

|

Carbon Steel |

Low |

Medium |

Medium |

Medium |

High |

Industrial |

|

Copper |

Medium |

Medium |

Medium |

High |

Medium |

Plumbing |

|

Aluminum |

Low |

Low |

Short |

Low |

Medium |

Lightweight |

|

PVC |

Low |

Low |

Short |

Low |

Medium |

Budget |

What are the standards and tolerances in pipe and tube manufacturing?

Understanding standard sizes and their importance

Regulatory documents such as ASTM A513 and ANSI B36.10/36.19 stipulate the standards and tolerances in pipe and tube fabrication, guaranteeing uniform precision, like outer diameter and wall thickness. These dimensions are vital to ensure seamless fit, safety, and functionality across multiple use cases.

Deciphering tolerance in pipe vs tube production

Pipes are produced in bulk and, as such, have looser tolerances and rougher surface finishes. In contrast, tubes are more slender and have finer surface finishes along with stricter manufacturing tolerances.

The impact of standard combinations of pipe nominal on usage

Standard combinations of pipe nominal sizes are critical in determining their applications across different sectors. These pipe nominal sizes, including the nominal pipe size (NPS) and schedule numbers, dictate a pipe’s flow capacity, pressure rating, and compatibility with fittings and valves. For example, in plumbing and HVAC systems, nominal pipe sizing directly impacts fluid or gas movement and overall system performance. Recent data from Google’s search engine suggests growing interest in the relationship between NPS, inner diameter (ID), and wall thickness, underscoring the need for accuracy in system design and optimization. These considerations additionally impact the selection of materials, cost-efficiency, and compliance with industry regulations.

Frequently Asked Questions (FAQs)

Q: What is the defining difference between pipes and tubes?

A: There are two significant distinctions between a tube and a pipe. First is their measurement; pipes are measured by ID, whereas tubes are measured by OD. Second is the purpose of use; tubes serve structural purposes while pipes transport fluids.

Q: How are a pipe and a tube outer diameters measured?

A: Both a pipe and a tube’s outer diameters are measured in inches and millimeters. In the case of a tube, its outer diameter is measured as the actual value. For pipes, their measurement is taken at a nominal value, which is important in terms of fluid capacity and flow.

Q: Is there a possibility to switch the terms of pipes and tubes?

A: There are certain terms, pipe and tube, which people use interchangeably and out of context. The two serve different purposes and measurement standards; hence, it is critical to understand the specifics of their intended use.

Q: What does “schedule” mean regarding a pipe?

A: “Schedule” signifies the thickness of a steel pipe’s wall. There are common schedules, such as schedule 40 pipe and schedule 80 pipe, where both differ in their wall thickness and therefore, pressure withstanding capacity.

Q: Why is Pipe ID more important than OD?

A: As for the pipes, ID is much more important than OD because it dictates how much fluid can be carried in the pipe. ID is influential in fluid dynamic systems and is essential in fluid transport-designed systems.

Q: How do tube sizes assist in structural considerations?

A: Tube sizes assist in structural consideration because they help determine the strength and stability of the structure. The actual outside diameter and wall thickness of the tube must control the loads and forces that are expected to be encountered to provide accurate protection against structural failure.

Q: How do straightness and roundness compare for tubes and pipes?

A: Straightness and roundness for both tubes and pipes are extremely vital as far as their quality and functionality are concerned. For structural purposes, the tube must be straight and round to ensure proper integration and protect the structural integrity.

Q: What is the application of construction pipes and tubes?

A: The transportation of fluids and gases makes use of Steel pipes, while structural applications that require precision and strength make use of tubes. Pipe designation is done based on ID and wall thickness for pipes, and tubes are selected for their wall thickness and structural capabilities.

Q: Explain what an NPS pipe is and how it relates to pipe sizes.

A: NPS (nominal pipe size) is a systematic method used for marking the size of a pipe. It serves to state the lineal diameter of the pipe with the aim of knowing what dimensions of pipes are available in the market, depending on the expected flow and usage of the pipe.

Reference Sources

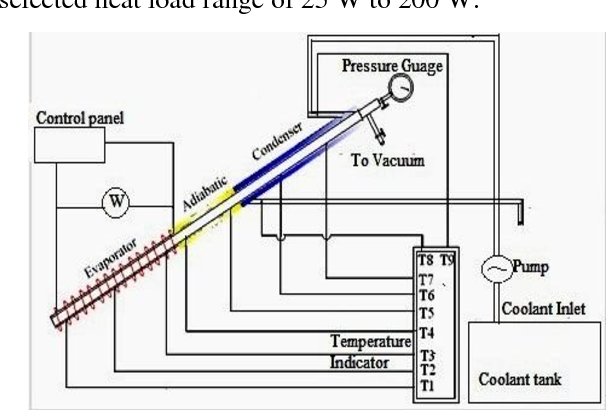

1. Title: Influence of the Filling Ratio on the Performance of Thermosyphon Heat Pipes

- Authors: Faddas Nikhil Ashok et al.

- Publication Year: 2015

- Citation Token: (Ashok et al., 2015)

- Summary: The principles regarding thermosyphon heat pipes are well understood; however, the influence of the filling ratio on their thermal performance remains underexplored. As such, the authors have conducted experiments aimed at evaluating the filling ratio on thermosyphon heat pipe performance, specifically its heat transfer efficiency. The results indicate that the filling ratio has a direct effect on performance, underscoring a critical parameter that can be controlled to optimize performance for engineering applications.

2. Title: Comparison of Qu-Tubes and Capillary-Pumped Heat Pipes in Aqueous Solution Heat Pipe Transport

- Author: K. Kihm

- Publication Year: 2013

- Citation Token: (Kihm, 2013)

- Summary: This work discusses the functionality of a new heat transfer device, Qu-tubes, in comparison to traditional capillary-pumped heat pipes. The study sheds light on some benefits offered by Qu-tubes, particularly their gravity-independent operation and superior thermal conductivity. The study offers an understanding of the operational limits and possible uses of these sophisticated thermal transport devices.

3. Title: Fabrication and Characterization of Heat Pipe With Composite Structure for the Adiabatic Section

- Authors: H. Parikh, Kedar Pathak

- Publication Year: 2020

- Citation Token: (Parikh & Pathak, 2020)

- Summary: This work investigates the design and function of a heat pipe featuring a composite structure in its adiabatic section. A new technique for adhesive bonding of composite and metal cores is suggested, along with the performance improvements of the heat pipe. Their findings support the theory that composite materials increase thermal conductivity, which is beneficial for heat pipe applications.

4. Difference With Pipe and Tube – Academia.edu