Modern engineering and manufacturing industries heavily depend on aluminum alloys because of their adaptability, strong build, and light weight. Notably, 6063 aluminum alloy is among the most appreciated and widely utilized in the aluminum industry. Its remarkable corrosion resistance, excellent strength-to-weight ratio, and machinability make 6063 a preferred option for everything from architectural frameworks to aerospace components. This guide will explain why 6063 aluminum alloy is popular by discussing its most important features, benefits, and main uses. This article aims to bolster project and decision-making processes from seasoned professionals to novices by arming readers with information and actionable insights.

What are the properties of 6063 aluminum?

6063 aluminum is highly resistant to mechanical damage and corrosion. The grade is also lightweight and malleable, making it easier to fabricate and shape into useful structures. The alloy is prized for its flawless surface finish, which is best suited for anodizing. It possesses fair weldability and modest machinability, making it an optimal candidate for precision and aesthetic applications: architectural parts, window frames, and signs.

Understanding the chemical composition of 6063 aluminum

6063 aluminum is made up of other elements such as magnesium and silicon. It usually holds 0.45-0.9% of magnesium and 0.2-0.6% silicon, which helps strengthen corrosion resistance and extrusion processes. Iron, copper, manganese, chromium, and zinc may also be present, but only in trace amounts. The mechanical properties of 6063 aluminum and its intermediate constituents result in exceptional surface quality, making it ideal for constructing objects where beauty and strength are desired.

Exploring the mechanical properties of 6063 alloy

6063 aluminum alloy is well-known to have a great middle ground in strengthening and resisting corrosion. Depending on the temper, such as T5 or T6, it has a typical tensile strength of 150-290 MPa, while T6 strengthened through heat treatment improves further. Its yield stress makes it lightweight at 110-240 MPa, which is advantageous for structural context. Also featuring good elongation properties, 6063 has an 8-12% yield, making extrusion malleable. Because of these aluminum features, it is easy to fabricate commandeered aerospace structures, architectural frameworks, and piping.

Examining the physical properties of 6063 aluminium

6063 aluminum is well-known for its high thermal conductivity, which usually ranges from 200 to 210 W/m·K. This makes it useful for heat exchangers and radiators, which need high heat dissipation. Also, its natural corrosion resistance, because of the protective oxide layer on its surface, allows it to perform better in environments where moisture and mild chemicals are present. This resistance works for little exposure to humidity and can be enhanced by anodizing, improving its strength and life span in harsh environments.

How does 6063 aluminum compare to 6061?

Comparing 6061 and 6063 in terms of tensile strength

Aluminum 6061’s tensile strength far surpasses that of 6063. The standard tensile strength for 6061 is around 45,000 psi, while 6063 tends to be in the ballpark of 27,000 psi. This illustrates why 6061 is preferred for anything that requires considerable strength, whereas 6063 is chosen when looks, corrosion resistance, or the simplicity of extrusion are valued.

Differences in corrosion resistance between 6061 and 6063

6061 aluminum is known to have good corrosion resistance, especially when it is in contact with fresh water or simply exposed to the atmosphere. Compared to 6063 aluminum, 6061 is more susceptible to corrosion due to the higher copper content. Conversely, due to its corrosion composition, 6063 aluminum possesses the best corrosion resistance, especially in marine or highly corrosive environments. For applications where further corrosion resistance is the primary focus, 6063 is the preferred option.

Why choose 6063 alloy for architectural applications?

The 6063 aluminum alloy is very popular for architectural use because its properties suit structural and aesthetic uses. The alloy has a wonderful extrudability, allowing it to form complex shapes needed for architectural parts like curtain walls, windows, and door frames. It also has great resistance to corrosion, which helps protect the alloy to ensure lasting durability in harsh environments. These industrial areas are constantly exposed to moisture and pollutants in coastal regions.

In addition, the 6063 alloy has outstanding surface finishes that can be improved further with processes such as anodizing and powder coating. Such ability makes it possible to produce modern architectural surfaces that require aesthetic appeal and added protection. Its mechanical strength is ideal for those features needing moderate load-bearing capabilities, thus making them appropriate for lightweight constructions. Compared with other materials and industry sources, 6063 aluminum also meets strict environmental protection and sustainability standards because of its recyclable nature and low energy consumption during production. All these reasons explain architects and designers’ choice of 6063 alloy as the best option to fulfill their needs for functionality, beauty, and responsible use of resources.

What are the applications of 6063 aluminum?

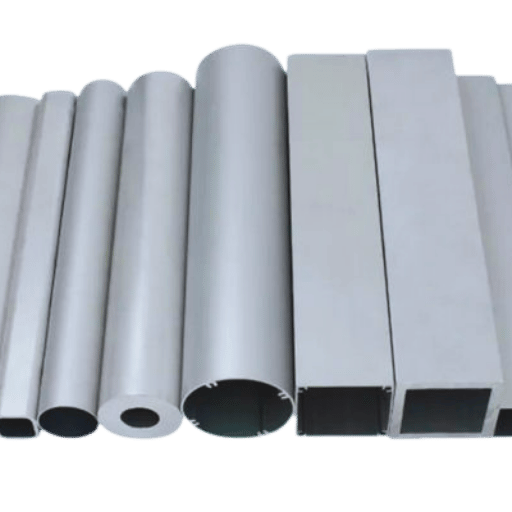

Using 6063 in window frames and door frames

6063 aluminum is commonly used in windows and doors because of its optimal strength-to-weight ratio, resistance to corrosion, and smooth surface finish. These characteristics are beneficial when crafting strong, light, and beautiful frames. The alloy’s good malleability ensures complicated designs are easy to achieve, while its environmental endurance guarantees performance durability in homes and businesses alike.

6063’s role in sign frames and railing

The combination of 6063 aluminum’s strength, corrosion resistance, and aesthetic appeal makes it a popular choice for framing signs and constructing railings. It is easy to fabricate and install because it is lightweight, easy to work with, and can endure the outdoors for long periods. Furthermore, 6063 aluminum’s smooth surface finish ensures a polished look, which is desired for functional and decorative structures.

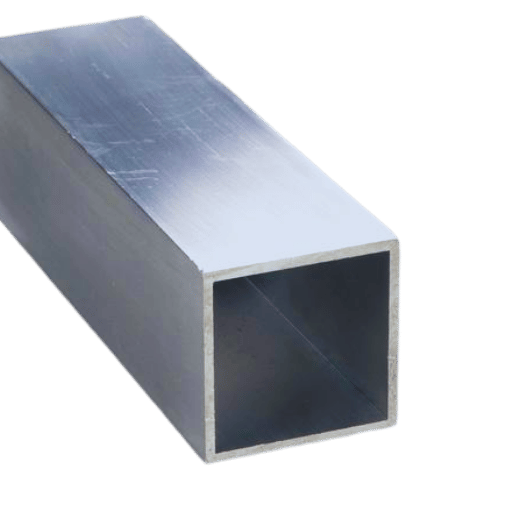

Why 6063 is perfect for irrigation tubing

6063 aluminum alloy is well adapted for irrigation tubing because of its excellent mechanical characteristics and resistance to environmental stress. The alloy’s high resistance to corrosion aids in protecting the moisture, soil, and agricultural fertilizers that could be damaging, guaranteeing a long service life even with constant exposure. In addition, its lightweight enables effortless transportation and installation of irrigation equipment, which assists in large-scale agriculture.

Additionally, 6063 is famed for its good extrudability, enabling complex designs to be manufactured with different profiles while maintaining consistent wall thickness, decreasing material waste. The tubing’s tensile strength, which is expected to fall between 27,000 and 38,000 psi depending on temper, guarantees that the tubing will endure water flow stresses applied from within without yielding or structural failure. In addition, the smooth surface finish of 6063 aluminum aids in minimizing friction losses when water is flowing, improving the overall efficiency of the irrigation system. These factors help support the argument that 6063 aluminum tubing is a wise and inexpensive option for modern farm irrigation systems.

How does extrusion affect 6063 aluminum’s properties?

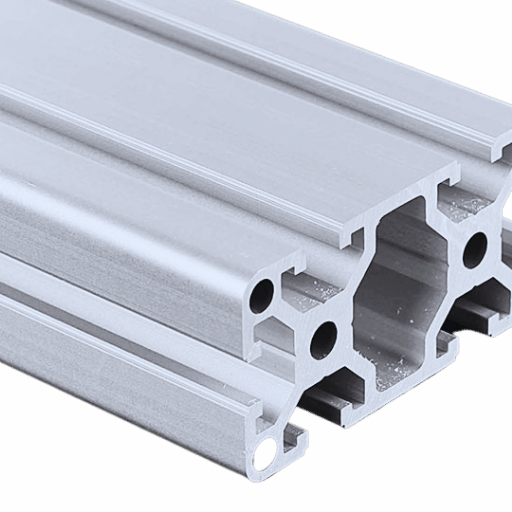

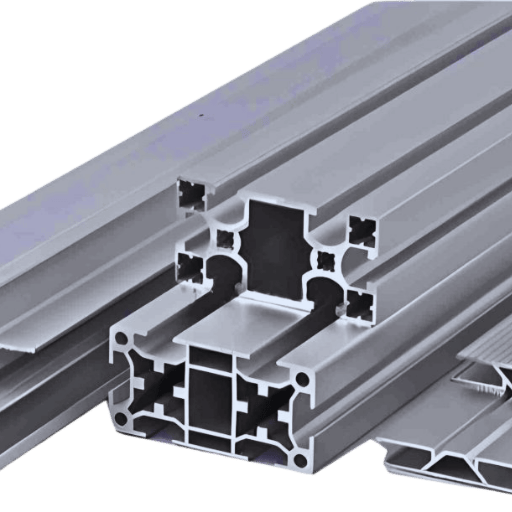

The process of extruding 6063 aluminum

To extrude 6063 aluminum, the aluminum alloy is forced through a die to achieve a particular cross-section. This process is done at high temperatures to soften the material and make it flow through the die more easily. The extrusion process achieves the enhanced character of the material’s strength, uniformity, and accuracy. It also enables the construction of lightweight and corrosion-resistant profiles tailored for different applications, particularly construction and manufacturing, which underscores its uses for 6063.

Impact of temperature on 6063 during extrusion

The extrusion process for 6063 aluminum alloy is susceptible to temperature. The initial heating before extrusion should fall within the optimal range of 900°F and 950°F (482°C to 510°C). The alloy becomes pliable enough to flow through the die without losing strength within this limit. For the wrong temperature, too low: the material becomes resistant to change, which will cause problems with the extrusion quality. Too high a temperature can cause surface issues and change the mechanical value of the product, which hurts the modulus of elasticity. Proper control over heat ensures a balance of ease of working with the material and how well the product functions.

Creating complex shapes with 6063 aluminum

6063 aluminum alloy is an essential material for applications that require complex and intricate shapes due to its excellent extrudability. 6063 aluminum also possesses low density, high corrosion resistance, and is more suitable than 6061 aluminum for lightweight structures, which are durable and have a long lifespan. The material can be easily extruded into complex geometries such as multi-hollow profiles and components with tight tolerances.

Newer methods of extrusion have improved the capabilities of 6063 aluminum even further. Advanced cooling systems and other components form uniform shapes with few surface defects. Due to 6063 aluminum’s superior response, additional protective and aesthetic anodizing is possible in architectural applications such as window frames, curtain walls, and ornate trims, making it a more appealing option.

Engineering data outlines the alloy’s moderately balanced mechanical properties, like tensile strength, typically around 186 MPa (27,000 psi), and Brinell hardness at around 60 HB. The ability to heat treat 6063 aluminum alloy (especially in T5 or T6 tempers) increases the alloy’s strength and wear resistance, enabling manufacturers to comply with strict industry requirements. These features make 6063 aluminum an adaptable option for industries that need precise structural profiles in complex designs.

What are the weldability and machinability of 6063 aluminum?

Understanding the weldability of 6063 alloy

6063 aluminum alloy is renowned for its superb weldability, especially when employing tungsten inert gas (TIG) or metal inert gas (MIG) welding. This alloy’s lower copper content than others reduces the risk of hot cracking during welding. Increasing the alloy’s strength and hardness post-weld may require heat treatment. For the best outcome, the filler alloy should closely match 6063.

Machining techniques for 6063 aluminum alloy

6063 aluminum alloy has good workability and moderate strength, making it ideal for machining operations. Its turning, milling, and drilling abilities can be performed using standard machining techniques. Sharp cutting tools should be used to achieve precision and quality, as well as the correct cutting speed and feed rates, which also boost the strength of the final product. Coolant during machining processes helps control temperature rise and reduce tool wear. Moreover, the softer characteristics of the alloy demand particular care to surface distortion when machining thin-walled parts due to deformation during machining.

Frequently Asked Questions (FAQs)

Q: What are the most notable properties of 6063 aluminum alloy?

A: 6063 aluminum alloy is well-known for its good mechanical properties, high strength-to-weight ratio, excellent resistance to corrosion, and workability. Because of its aesthetic value, it is sometimes referred to as architectural aluminum and is used extensively in aluminum extrusions.

Q: How do the material properties of 6063 aluminum and 6061 aluminum compare?

A: Even though 6063 and 6061 are parts of the 6000 series and have magnesium and silicon as the principal alloying elements, 6061 aluminum typically has greater yield strength and ultimate tensile strength, giving it an edge for structural uses. On the other hand, 6063 has much better workability and is more desirable for applications where a good surface finish is essential.

Q: What are some of the common uses for 6063 aluminum?

A: 6063 aluminum is commonly used to extrude windows and doors, irrigation tubing, frames, and recreational equipment. Its aesthetic value also makes it a preferred option for architectural products, especially when used with 6061 and 6063 aluminum.

Q: Why is the 6063-T6 temper designation critical?

A: The 6063-T6 designation means a certain level of strength and hardness has been achieved with the alloy’s heat treatment process. The “T6” temper includes treatment with the specific steps of solution heating followed by artificial aging, where an alloy and aging are done to improve the ultimate tensile and yield strength of the alloy.

Q: What changes does heat treatment bring to aluminum 6063 properties?

A: Heat treatments such as T5 and T6 accelerate the strength and hardness of the 6063 aluminum alloy considerably. They alter the distribution and amount of magnesium and silicon alloying constituents, improving thermal behavior and performance on many levels.

Q: Is it possible to easily weld 6063 aluminum?

A: Various welding methods can be applied to join 6063 aluminum, which makes it easy to weld. This means it can easily be used in industries that need intricate shapes and designs that can be formed by aluminum extrusion.

Q: How thermally conductive is 6063 aluminum?

A: 6063 aluminum is thermally conductive, which makes it ideal for use in heat exchangers and places where dismantling a setup for cores issuing heat is necessary. Due to its melting points and other specified thermal attributes, it can be an effective material in several thermal control devices.

Q: What are the 6063 and alloy 6061 variations in construction applications?

A: In construction applications, 6063 is more appealing aesthetically and easier to work with, whereas alloy 6061 is stronger and has better load-bearing capabilities. The decision between the two varies with the project’s demand, such as needing a high strength-to-weight ratio or a smooth surface.

Q: What makes 6063 a widely used alloy for aluminum products?

A: 6063 is a widely used alloy because it has good mechanical properties and is easy to fabricate. It can be extruded to create beautiful and complex forms, and it is corrosion resistant, which makes it suitable for many aluminum products.

Reference Sources

1. Effect of Excitation Settings on Surface Finish in Magnetorheological Finishing of 6063 Aluminum Alloy

- Authors: Yiming Fang, Jinzhong Wu

- Published in: Materials Volume 17 June 2024

- Key Findings:

- The research analyzes the impact of magnetorheological finishing with a low-frequency alternating magnetic field on the 6063 aluminum alloy’s magnetorheological polishing performance.

- Critical excitation parameters like current, frequency, excitation gap, and iron powder granulometry were studied.

- The best surface roughness result for the sample was achieved at 1 Hz, when surface roughness was improved to 3.54 nm from 285 nm.

- Methodology:

- A single-factor experiment was used.

- The surface was assessed with a Zigo non-contact white light interferometer (Fang & Wu, 2024).

2. Assessment and Enhancing the Efficiency of Eco-Friendly Sustainable Turning of 6063 Aluminum Alloy in Dry Conditions Using Grey Relational Analysis

- Authors: A. Kannan, N.M Sivaram

- Published in: International Journal of Automotive and Mechanical Engineering, March 2024

- Key Findings:

- Every eco-friendly machining method relative to 6063 aluminum alloy was analyzed, and the turning parameters for performing the methods were rounded.

- The most economical turning performance was accomplished at a cutting speed of 200 m/min, a feed of 0.05mm/rev, and a depth of cut of 0.25mm.

- Carbon emissions were reduced by 72.84%, energy consumption by 72.82%, and surface roughness by 6.83%.

- Methodology:

- The machining processes’ characteristics and sustainability indicators are evaluated using grey relational analysis (GRA) and ANOVA (Kannan & N.M. Sivaram, 2024).

3. The Microstructure and Properties of MAO/PA/MoS2 Composite Coating on 6063 Aluminum Alloy by Micro Arc Oxidation

- Author: X. Qi, Hong Gao, Yafeng He, X. Su, Renguo Song

- Published: Surface & Coatings Technology, April 2024

- Key Findings:

- This work describes the structural and compositional properties of a composite coating on 6063 aluminum alloy.

- MAO (Micro Arc Oxidation) was performed to improve the properties of the alloy surface.

- Methodology:

- The formation of the composite coating and its characterization are given in the paper. The authors avoided specific descriptions of experiments in the abstract (Qi et al., 2024)